Customized extraction systems for your needs

Customized extraction systems

Low maintenance & durable

Energy-saving & future-proof

Customized extraction systems

The right system for your industry

and your process.

Expert maintenance & cleaning

To ensure smooth operation, we maintain

and clean systems from all manufacturers.

Looking for a cool sock!

Apply as an electrician, mechatronics engineer, mechanic or product designer. Easy in 60 seconds without Vita!

WERKER News

Why do dust, welding fumes or oil mist need to be extracted effectively?

Did you know? In industrial environments, the extraction of dust, welding fumes and oil mist is crucial: It ensures occupational health and safety, improves product quality, extends machine service life and ensures compliance with regulations.

The ABSAUGWERK principle

Process analysis

Insufficient capture, low suction power, incorrect placement and filter selection impair the efficiency of many extraction units.

Customized systems

We develop and manufacture custom-fit extraction solutions, from A for extraction arms to Z for supply air. This increases safety in your production!

Lower follow-up costs

A customized extraction unit reduces long-term operating costs in terms of maintenance, energy and productivity. This makes them a sustainable and economical investment.

We find a solution – for every industry and every process

Our customers about ABSAUGWERK …

Our customers

More than just standard!

The specific requirements of a company often demand more than standardized systems can offer. Customized extraction systems from ABSAUGWERK, on the other hand, are characterized by higher efficiency by meeting individual needs more precisely, are ATEX-certified in potentially explosive environments and contribute to long-term cost savings. We create holistic solutions consisting of pipe systems, captures, extraction units and discharges. Our wide range of accessories extends from cyclone pre-separators to extraction arms and special discharge systems, accompanied by comprehensive service.

Pipe systems

Folded spiral duct

Flared spiral duct

Longitudinal seam-seamed duct

Longitudinal seam-seamed duct with shelf

Captures

Extraction arms

Extraction hoods

Extraction tables

Machine connection

Individual captures

Extraction systems

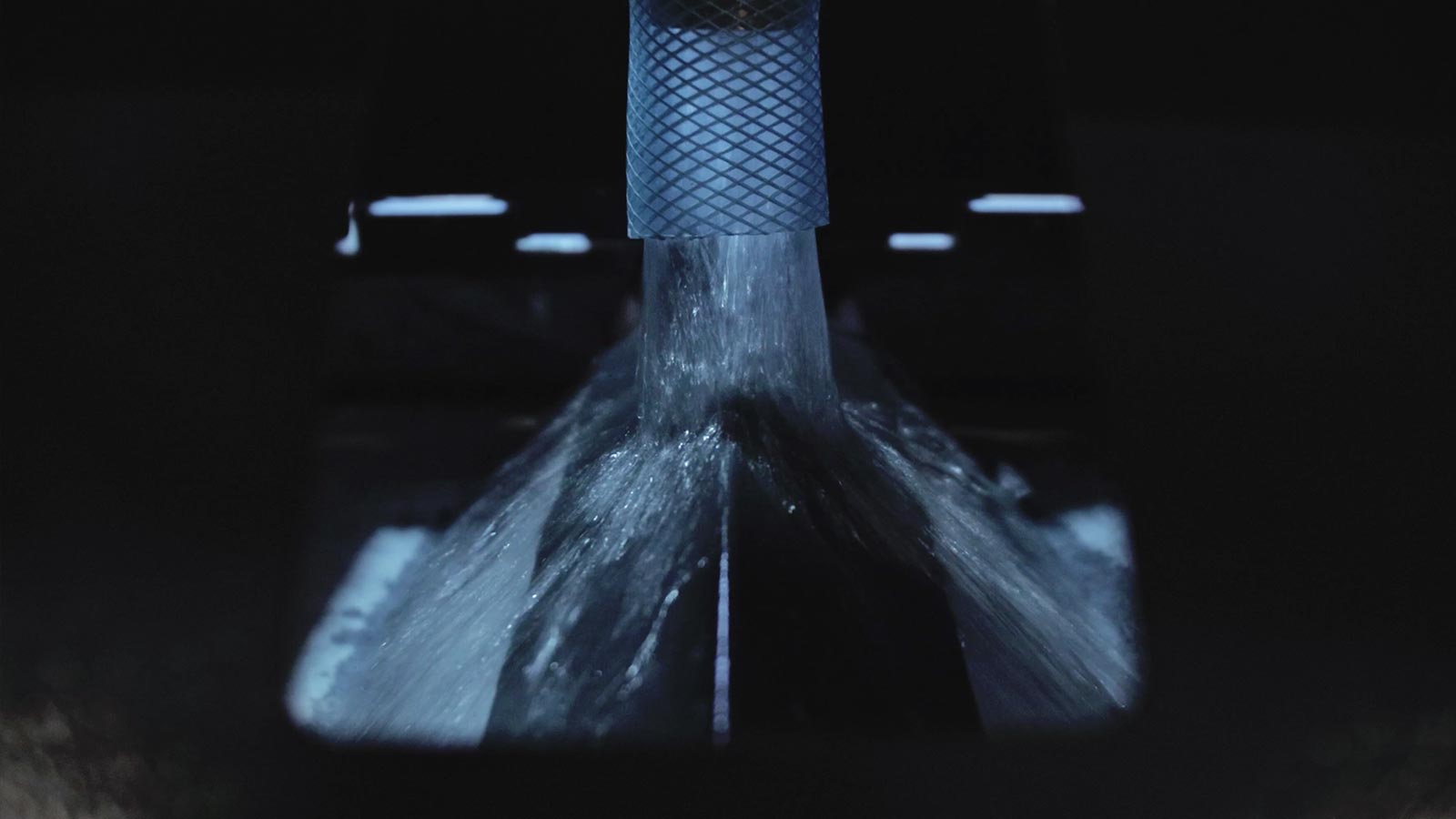

Wet separator

dedusters

fume filters

Oil mist separator

filter tower

Discharges

Bucket

Drawer

Container (dry)

Sludge container

Automatic discharge

Extraction cabins

Direct extraction at relevant sources

Hall extraction

Effective extraction in large production facilities

Equipment

Precoat unit

Precoater

Cleanbox

360° Service

Consulting

Planning

Assembly & installation

Training

Cleaning & maintenance

After-sales

Made in Neu-Ulm

The »Made in Neu-Ulm« extraction systems are manufactured and tested according to strict quality criteria. Certifications from recognized institutions such as TÜV, DGUV (IFA) or BSFZ guarantee compliance with the highest standards.

ATEX extraction systems

Take extra care when working with flammable and explosive materials (aluminum, stainless steel, flour, etc.). Special ATEX directives apply here for extraction systems.

Maintenance & Service

Our experts ensure the reliable operation of your extraction units: from regular maintenance and preventive inspections to rapid support in the event of a malfunction. This ensures that your systems remain efficient and safe in the long term.

5 steps to a sustainable production plant:

Protect your employees and become an attractive employer in the region!

👨💻

Process analysis

In the first step, your work processes are examined, sources of pollutants analyzed and existing extraction systems checked. Your extraction requirements are evaluated on this basis.

💬

Personal on-site appointment

We will then be happy to arrange an appointment for a personal consultation. Our experts will take measurements on site to precisely record your individual requirements.

✍️

Individual offer

After analyzing your specific requirements and creating technical drawings, we look for the most cost-effective solution. You will receive a customized offer.

🏭

Production

Once the order has been placed, we start production of your extraction unit immediately. Our modern technologies and dedicated professionals ensure maximum efficiency and quality to ensure that your extraction unit meets the highest standards.

🔧

Assembly

Your extraction system is installed by our own installation team; if necessary, we call in external partners. In this way, we guarantee professional installation and perfect functionality.

Air pollution control

Saving energy

Conserving resources

With our innovative and sustainable extraction technology, you contribute to a sustainable industry and a healthy environment.

Who are we?

✓ Pioneering spirits

✓ Developer

✓ Air purifier

✓ real. Uuulmer.

✓ On the road in D-A-CH & Europe

✓ Top sponsor of BBU

We invite interested parties to visit our WERK in Neu-Ulm or realized customer projects in your area.