FILTER TOWER

R SERIESPlug & Play filter tower for the industry

Filter towers are powerful extraction systems for welding fumes, dust and smokes. They are used when point extraction is impractical or insufficient to meet dust limits. The Plug & Play filter tower runs in recirculation mode, is powerful and very quiet at the same time. The quick start-up and small footprint make filter towers an efficient shop ventilation system for welding, tacking, cutting and other processes.

Filter towers as flexible hall extraction

The mobile extraction system for industrial halls for the extraction of welding fumes and dust can be installed quickly and easily according to the plug & play principle. The installed EC fans with IE5 technology are energy-saving, quiet and at the same time enormously powerful. The adjustable power control makes the filter tower a flexible and energy-saving room ventilation system. Heat recovery can also save up to 70% on heating costs.

-

Plug & Play in only 1 min

-

Efficient welding fume extraction & air purification

-

Hall extraction without pipe system

-

Compliance with workplace limits (TRGS 528 and ArbStättV § 3a)

-

Up to 70% heating cost savings

-

Only 1.56 m² space requirement

-

Energy-saving recirculation mode

%

LONGER

FILTER LIFE

DRAUGHT-FREE

ALL-ROUND DISCHARGE

%

HEATING COST SAVING

LOWER

SOUND LEVEL

Quiet, energy efficient and flexible

Our filter towers are more powerful, quieter and at the same time require less energy than conventional devices. The extraction systems can replace a complete hall extraction or hall ventilation system and do not require a pipe system. In this way, dust limit values can be better observed and the air quality for the employees is improved enormously.

Space saving filter tower

Floor space is in short supply in any production hall. Therefore, when developing our filter tower series, we paid attention to a minimum space requirement with maximum performance. The extraction units require only 1.56 m² of floor space and no piping.

Subscribe to our YouTube channel!

There we regularly publish new service and product videos on filter towers, hall extraction and other extraction systems to make the use of our extraction systems even more customer-friendly.

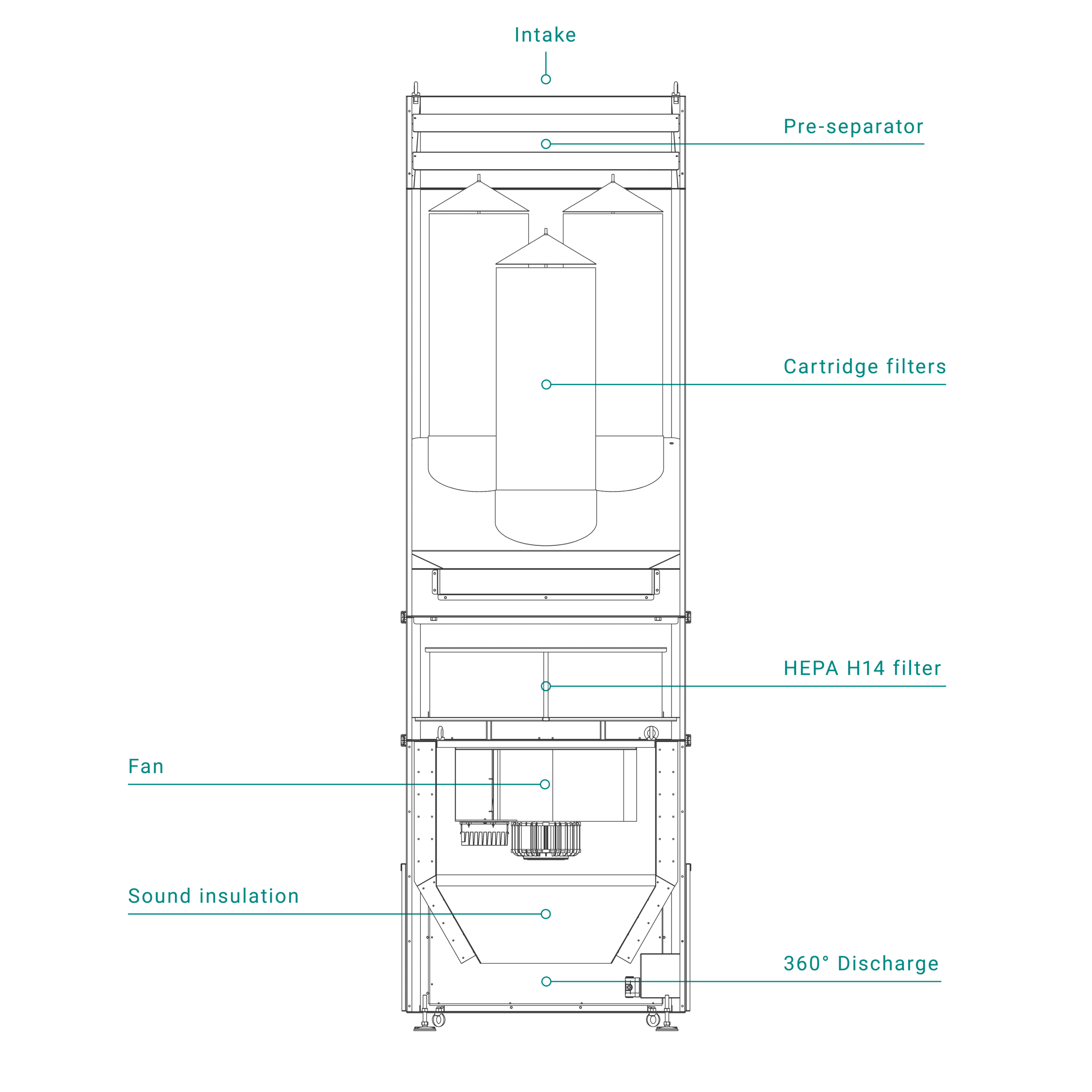

Filter Tower Functionality

A proven system in hall ventilation is stratified ventilation, which is recommended by professional associations and the IFA. Its thermal properties cause the contaminated, warm air to rise to the top. There it is extracted at the intake area at the top of the filter tower and cleaned via several filter stages. The clean air is returned to the room without drafts via the outlet near the floor. This creates a protected zone for employees and machines with almost outdoor air quality.

Clean air: layer by layer!

Unit components filter tower

FILTER

- Permanent filter cartridges

- Dust class M

- Automatic Jet Pulse cleaning

TECHNICAL DATA

- Motor power: 4.3 kW

- Operating point: 12,500 m³/h

- Weight: approx. 900 kg

INSTALLATION

- Electricity and compressed air connection

- No piping necessary

- Safe installation due to crane eyes

Options filter tower

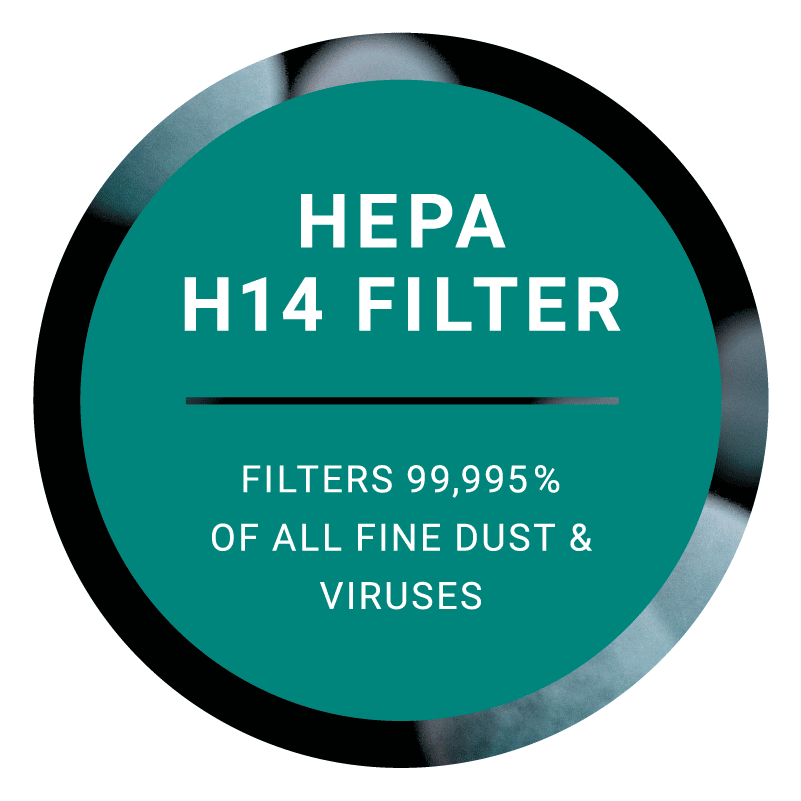

HEPA H14 FILTER

Against carcinogenic substances

COLOR & BRANDING

Individual as desired

HEPA H14 FILTER

Against carcinogenic substances

COLOR & BRANDING

Individual as desired

Environmental protection & sustainability

We develop economical and energy-saving filter towers using the latest technology. R Series filter towers are equipped with long-life filter components, are energy efficient and can achieve heating cost savings of up to 70%.

High-quality processing

for a long service life

Less energy costs

per year

High volume

HEPA H14 Filter

Summer/winter switchover

through intelligent control

Reduced heating costs

due to cross heat exchanger

Low maintenance and

less cleaning effort

Noise protection through

soundproofed construction

Manual regulation

of the air output

Secure up to 40 % state subsidy!

The Federal Office of Economics and Export Control (BAFA) and the Reconstruction Loan Corporation (KfW) offer a federal subsidy program to increase energy efficiency in industry. Small and medium-sized companies receive a subsidy of up to 40% for filter towers and systems for hall extraction. Funding is limited to a maximum of € 200,000 per investment project. Get advice from your energy consultant.

Related Links:

Air purification with filter towers in industry:

HEPA filters clean the air of viruses, bacteria, fine dust and other small particles!

The R series filter tower effectively filters harmful substances such as carcinogenic stainless steel dusts, viruses & bacteria, allergens, mold spores and other pathogens from the air you breathe. This not only has a positive impact on the health of your employees, but also significantly reduces the burden on the environment and the economy.

We achieve this with so-called HEPA filters of class H14, which are also used in operating theatres. The filters can be optionally added to the filter towers and have a separation efficiency of 99.995%.

Filter tower references

Other filter towers were significantly louder with less power!

»We opted for the ABSAUGWERK...

Significantly higher performance than competitors!

»The performance of the filter tower clearly stands out...

Other filter towers were significantly louder with less power!

»We opted for the ABSAUGWERK...

Significantly higher performance than competitors!

»The performance of the filter tower clearly stands out...Filter tower inquiry – simple & non-binding

We offer comprehensive technical planning and advice on our filter towers and extraction systems. Our technical sales team will find the right extraction solution for your process and provide you with a no-obligation quote.

Filter tower for welding fumes

Welding poses a particularly high risk to health, regardless of the welding process or material. Welding fume consists of ultra-fine fume particles that settle deep into the alveoli. Inhalation of chromium and nickel compounds during stainless steel welding can even lead to cancer. Effective extraction is therefore essential.