VDI 2263:

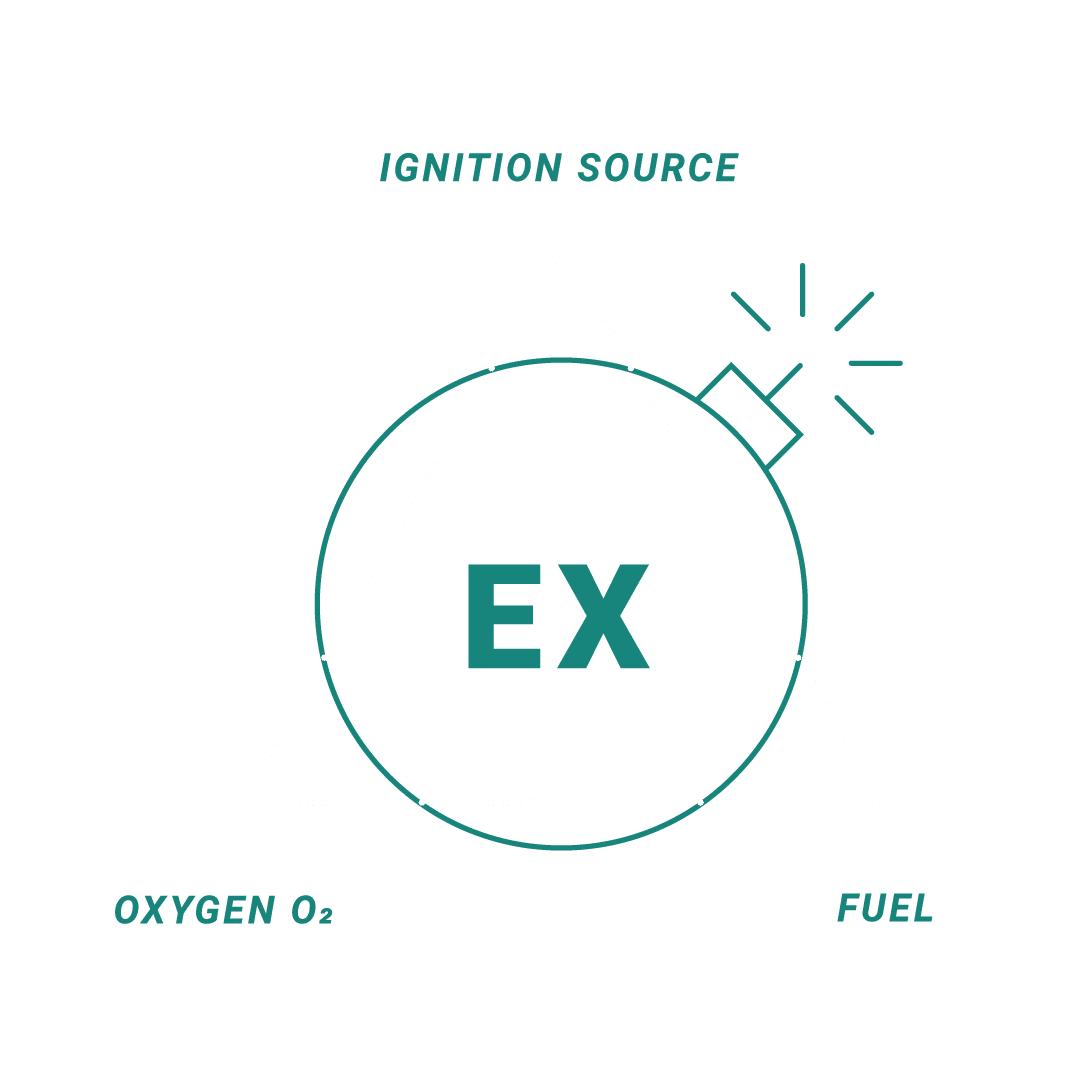

Dust fires and dust explosions; hazards, assessment, protective measures

VDI 2263 sheet 1:

Dust fires and dust explosions; hazards, assessment, protective measures; test methods for determining safety-related parameters of dusts

VDI 2263 sheet 2:

Dust fires and dust explosions; hazards, assessment, protective measures; inerting

VDI 2263 Sheet 3:

Dust fires and dust explosions; hazards, assessment, protective measures; explosion pressure shock resistant containers and apparatus; calculation, construction and testing

VDI 2263 sheet 4:

Dust fires and dust explosions; hazards, assessment, protective measures; suppression of dust explosions

VDI 2263 sheet 5:

Dust fires and dust explosions; hazards, assessment, protective measures; explosion protection in fluidized bed plants

VDI 2263 sheet 5.1:

Dust fires and dust explosions; hazards, assessment, protective measures; explosion protection in fluidized bed plants; instructions and design examples for manufacturers and operators

VDI 2263 sheet 6:

Dust fires and dust explosions; hazards, assessment, protective measures; fire and explosion protection at dust extraction plants

VDI 2263 sheet 6.1:

Dust fires and dust explosions; hazards, assessment, protective measures; fire and explosion protection on dust extraction systems; examples

VDI 2263 sheet 7:

Dust fires and dust explosions; hazards, assessment, protective measures; fire and explosion protection at spray drying plants

VDI 2263 sheet 7.1:

Dust fires and dust explosions; hazards, assessment, protective measures; fire and explosion protection at spray drying plants; examples

VDI 2263 sheet 8:

Dust fires and dust explosions; hazards, assessment, protective measures; fire and explosion protection on elevators

VDI 2263 sheet 8.1:

Dust fires and dust explosions; hazards, assessment, protective measures; fire and explosion protection on elevators; examples

VDI 2263 sheet 8.2:

Dust fires and dust explosions; hazards, assessment, protective measures; explosion suppression and combination of constructive protective measures on elevators

VDI 2263 sheet 9:

Dust fires and dust explosions; hazards, assessment, protective measures; determination of the dust behavior of bulk materials

VDI 3673 sheet 1:

Pressure relief of dust explosions

DIN EN 1127-1:

Explosive atmospheres, explosion protection,

Part 1: Basic principles and methodology

DIN EN 1127-2:

Explosive atmospheres, explosion protection,

Part 2: Basic principles and methodology in mines

DIN EN 1755:

Industrial trucks – Safety requirements and verification – Additional requirements for use in potentially explosive atmospheres

DIN EN 14491:

Protective systems for the pressure relief of dust explosions

DIN EN 14986:

Design of fans for use in potentially explosive atmospheres Avoidance of ignition hazards due to electrostatic charges