noise protection

for extraction systems and extraction cabins

Noise protection in extraction technology

Sound insulation in industry is crucial, as workplace noise endangers the health and performance of your employees. Long-term exposure to noise leads to hearing damage, stress and other health problems. Did you know that the most common occupational disease in Germany is noise-induced hearing loss? Companies are therefore required to comply with regulations such as the Workplace Ordinance, which demands low sound pressure levels in order to minimize health risks.

Decibel dynamics: benchmark for volume and health

Decibel is a logarithmic unit of measurement used to measure sound. The relationship to perceived loudness is not linear, but depends on the sensitivity of the human ear.

On the decibel scale, the quietest audible sound is 0 dB. Even an increase of 10 dB is perceived as a doubling of the volume. Each further increase of 10 dB corresponds to an exponential increase, for example 20 dB means a sound that is 100 times stronger, and so on.

Every decibel is important, especially with extraction systems or work cabins, but also with other machines. Even small reductions in sound can have a significant impact on perceived loudness and potential health effects.

The sound level of our extraction systems is between approx. 68 and 79 dB, depending on the appliance and power rating. This corresponds roughly to the volume of a normal to loud conversation, a typewriter or a passing car. The noise level is in the moderate range, is perceived as acceptable in an everyday environment and does not cause any immediate damage to hearing. We can achieve even lower sound levels with additional soundproofing techniques.

Noise protection measures for extraction systems and filter systems

There are various techniques for soundproofing extraction systems in order to minimize the noise level in production halls. It should be emphasized that the selection of suitable noise control measures depends on various factors, including the specific type of filter system (wet separator, deduster, oil mist separator), local regulations and the individual requirements of the workplace.

Extraction of several sanding cabins with robot

Sound insulation

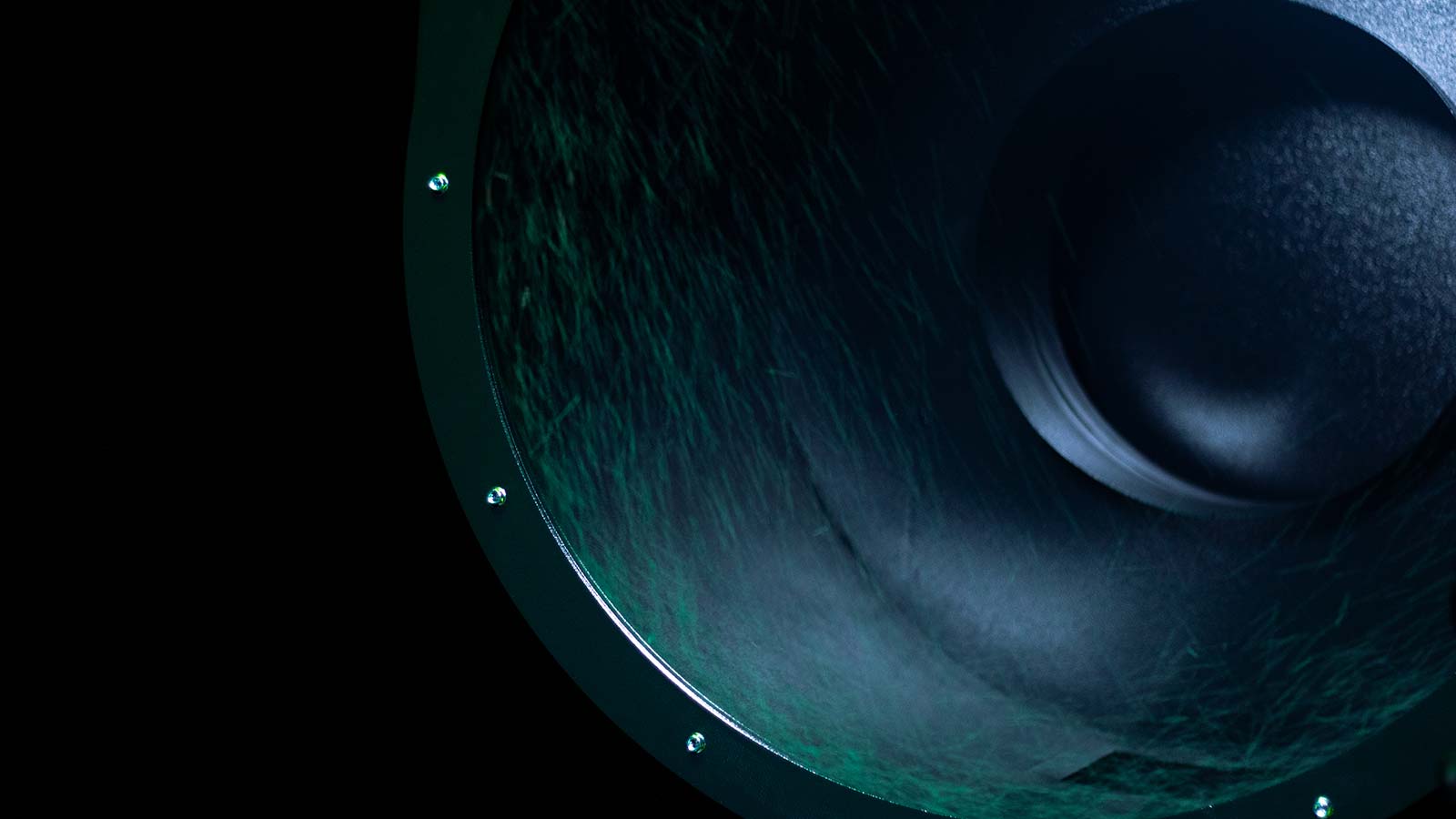

Use of sound-absorbing materials, such as special sound-insulating hoods or cabins.

Silencer

Integration of silencers in the exhaust air ducts of the extraction system and the pipelines.

Vibration damping

Use rubber mats or rubber pads to dampen vibrations.

Distancing

Spatial separation between the extraction system and the work areas.

Maintenance & servicing

Regular maintenance for proper function and minimal noise development.

Quieter components

Use of quiet fans, motors and other extraction system components.

Soundproofing technology & soundproof cabins

The use of modern, quiet extraction systems is crucial for compliance with noise limits and makes a positive contribution to the working environment, health and performance of the company. Extraction cabins also play an important role, not only by effectively extracting pollutants, but also by reliably absorbing noise emissions. Note that the effect of soundproofing on extraction systems depends on various factors, but in many cases can contribute to an overall more efficient working environment.

Sound insulation components

- Stable and low-vibration construction

- Quiet, smooth-running fans

- Vibration damper

- Pre-separator for coarse material

- Optimized piping systems with a smooth inside, larger radii and smooth transitions

- Cyclical material discharge

- Intelligent SIEMENS LOGO! Control

with day and night operation - Soundproof cabins

Limits & measures

The specified noise levels and action values are part of the statutory regulations on noise protection in the workplace. The measures required here depend on the noise exposure levels measured:

With a daily noise exposure level LEX, 8h of 80 dB(A) or a peak sound pressure level LpCpeak from 135 dB(C):

- Information for employees

(when the trigger value is reached) - Provision of hearing protection

(if the trigger value is exceeded) - Offer of occupational health care

(if the trigger value is exceeded)

With a daily noise exposure level LEX, 8h of 80 dB(A) or a peak sound pressure level LpCpeak from 135 dB(C):

- Information for employees

(when the trigger value is reached) - Provision of hearing protection

(if the trigger value is exceeded) - Offer of occupational health care

(if the trigger value is exceeded)

Legal requirements

Various regulations and directives govern noise protection in the workplace, including the German Noise and Vibration Occupational Healthand Safety Ordinance (LärmVibrationsArbSchV), which sets limit values and prescribes noise reduction measures.

EU Directive 2003/10/EC also lays down minimum requirements for occupational noise protection .

Workplace regulations, as in Germany, emphasize the responsibility of employers to minimize sound pressure levels through measures such as hearing protection, optimization of work processes and soundproofed rooms. In Germany, these guidelines can be found in the Technical Rules for Workplaces ASR A3.7.