Fire protection

for extraction systemsPreventive fire protection in extraction technology

Fires are caused by the combination of oxygen, an ignition source and combustible material. Unlike explosions, they are often not immediately recognizable. Deposits in the pipe system or the extraction system itself, can cause dangerous smoldering nests, which do not immediately form high smoke columns and can remain unnoticed for a long time. For this reason, preventive fire protection measures for exhaust systems as well as effective monitoring and extinguishing systems are absolutely necessary.

Fire protection technology by ABSAUGWERK

Fires in industrial plants can severely damage employees, machines and production halls and endanger the existence of a company. Metalworking processes such as flexing, grinding or polishing generate dust and sparks that can enter the filter systems during extraction and pose a constant fire hazard. Here, a microprocessor-controlled object protection extinguishing system in accordance with DIN14497 with rapid fire detection provides safety and prevents fires or smoldering nests in extraction systems.

Such safety equipment primarily protects the workforce, but also workpieces, machines, material and buildings.

Fire protection investment vs. follow-up costs:

If the follow-up costs of a fire, such as repairs, production downtimes and delivery delays, are put in relation to the initial costs of a property protection extinguishing system, the marginal investment for the necessary fire protection measures becomes apparent.

Together with Kraft & Bauer, a renowned manufacturer of fire extinguishing equipment, we have developed a multi-stage fire protection concept for our extraction systems based on the preventive fire protection principle. ABSAUGWERK’s fire protection measures offer a reliable solution for detecting and effectively combating sources of fire before they arise. The fire protection concept of our extraction systems thus not only complies with legal requirements, but also prevents fires preventively and minimizes possible damage and subsequent costs.

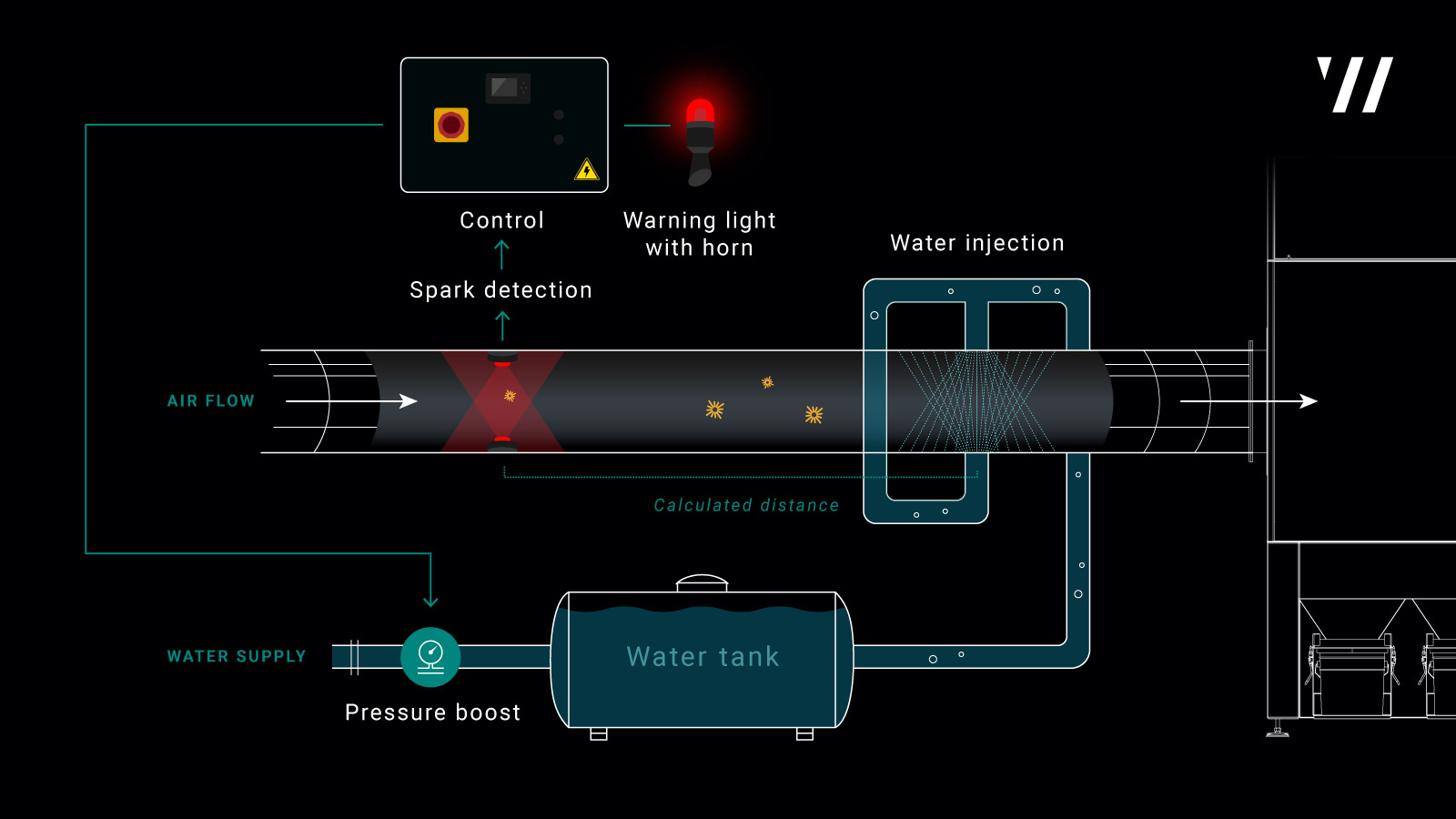

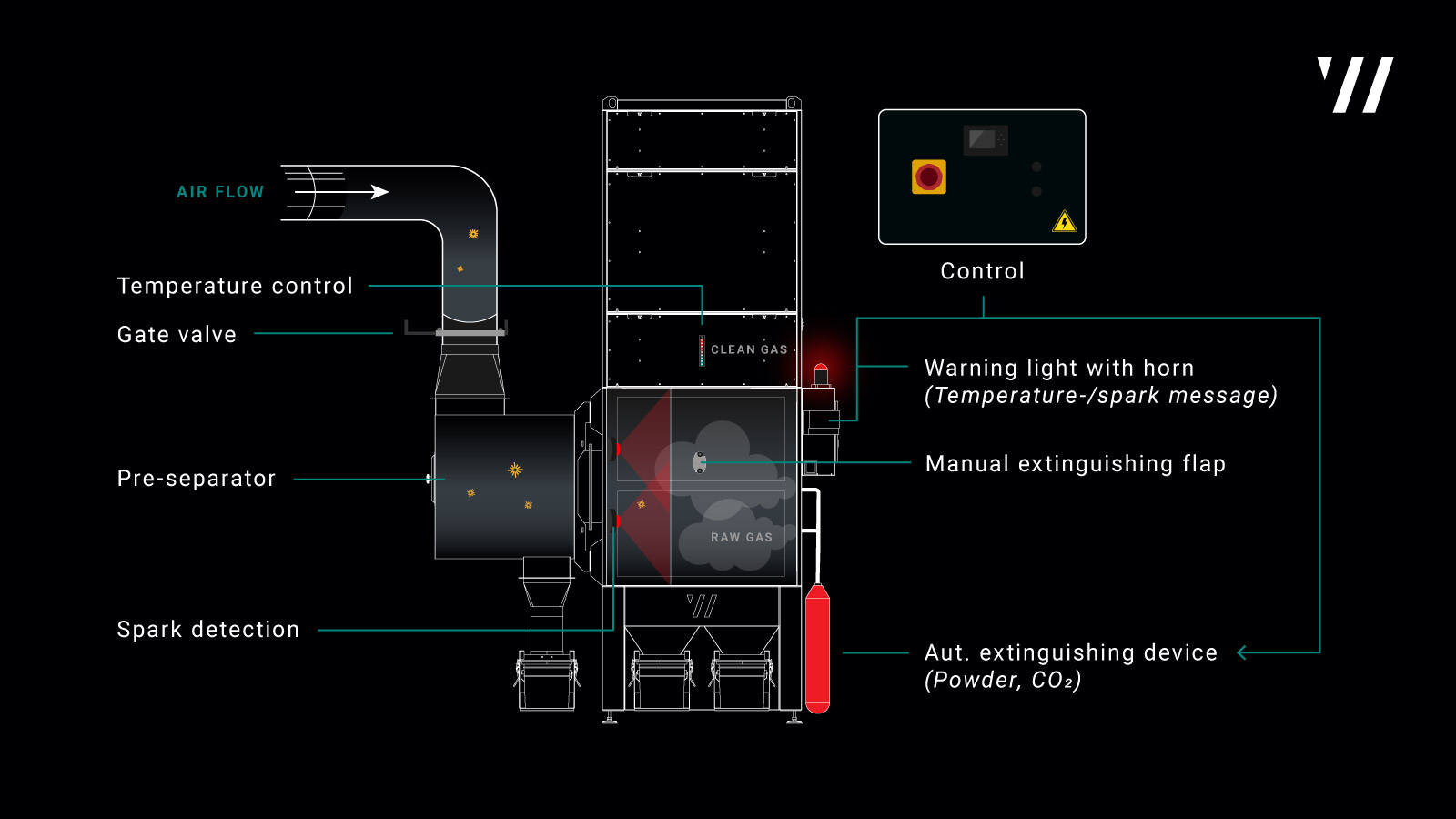

Sparks are already detected and extinguished in the pipe system by sensors.

If a spark gets into the filter system, additional extinguishing devices are used.

The design principle of our systems is based on preventive fire protection measures that eliminate and monitor possible sources of fire in advance. This is achieved through maximum separation efficiency, high air velocities and special fire protection components.

Fire protection components dry extraction

- Pre-separator

- Spark detection

- Automatic extinguishing device: water, powder, CO2

- Smoke detector (optical, thermal)

- Gate valve

- Extinguishing flap (manual extinguishing)

- C-connection for flooding

- High air velocity in the pipe min. > 20 m/s

- Automatic shutdown of the system

- Construction free of ignition sources and conductive

- Negative pressure and volume flow monitoring

- Automatic cleaning (offline)

- Precoat unit

Fire protection components wet separator

- Pre-separator

- Spark detection

- Automatic extinguishing device: water, powder, CO2

- Smoke detector (optical, thermal)

- Gate valve

- Extinguishing flap (manual extinguishing)

- C-connection for flooding

- High air velocity in the pipe min. > 20 m/s

- Automatic shutdown of the system

- Construction free of ignition sources and conductive

- Negative pressure and volume flow monitoring

Legal requirements

The responsibility within the framework of production and occupational safety for fire protection measures lies solely with the operator. With this in mind, we are happy to offer you individual advice and recommend the use of an effective extraction system.

Fire protection checklist

We recommend the following measures:

- Hazard assessment by an accredited fire and explosion protection officer, e.g. TÜV, DEKRA, insurance company

- Keeping a fire protection regulation ready

- Operation of the loading equipment only by trained personnel

- Regular fire drills

- Keeping an extinguishing bottle ready

- Annual maintenance and cleaning of the system

- Regular emptying of the discharge system

»Together, we have professionally developed a strong protection concept with ABSAUGWERK, which enables the optimal ratio of price/performance and safety, respectively, for the customer.«