Why extraction

Safe production and occupational safety by extracting emissions

Lower costs

Lower disposal costs as raw materials or water can be separated from the waste

Recycling

Saving of raw materials through reuse of e. g. chips and granules

Cleanliness

Less effort for cleaning machines and halls

No odors

Neutralization of odors such as food, varnishes

Accident protection

Less risk of slipping due to dirty floors and work surfaces

Fire/ex protection

Preventive explosion and fire protection through safe extraction and pipe systems

Environmental protection

Clean air ensures a healthy environment and significantly supports climate protection

Occupational safety

Respirable substances can cause serious respiratory diseases or cancer

Human

The extraction of respirable dusts, paint residues, oil mists and similar substances, ensure the protection and safety of employees.

Machine

Less deposits and contamination. This guarantees the quality of your workpieces and ensures the longevity of machinery and tools.

Environment

Our customized systems consume only the amount of energy and water that is needed. The clean air can either be led outside or back into the hall via a heat recovery system. This significantly saves heating costs and protects the environment.

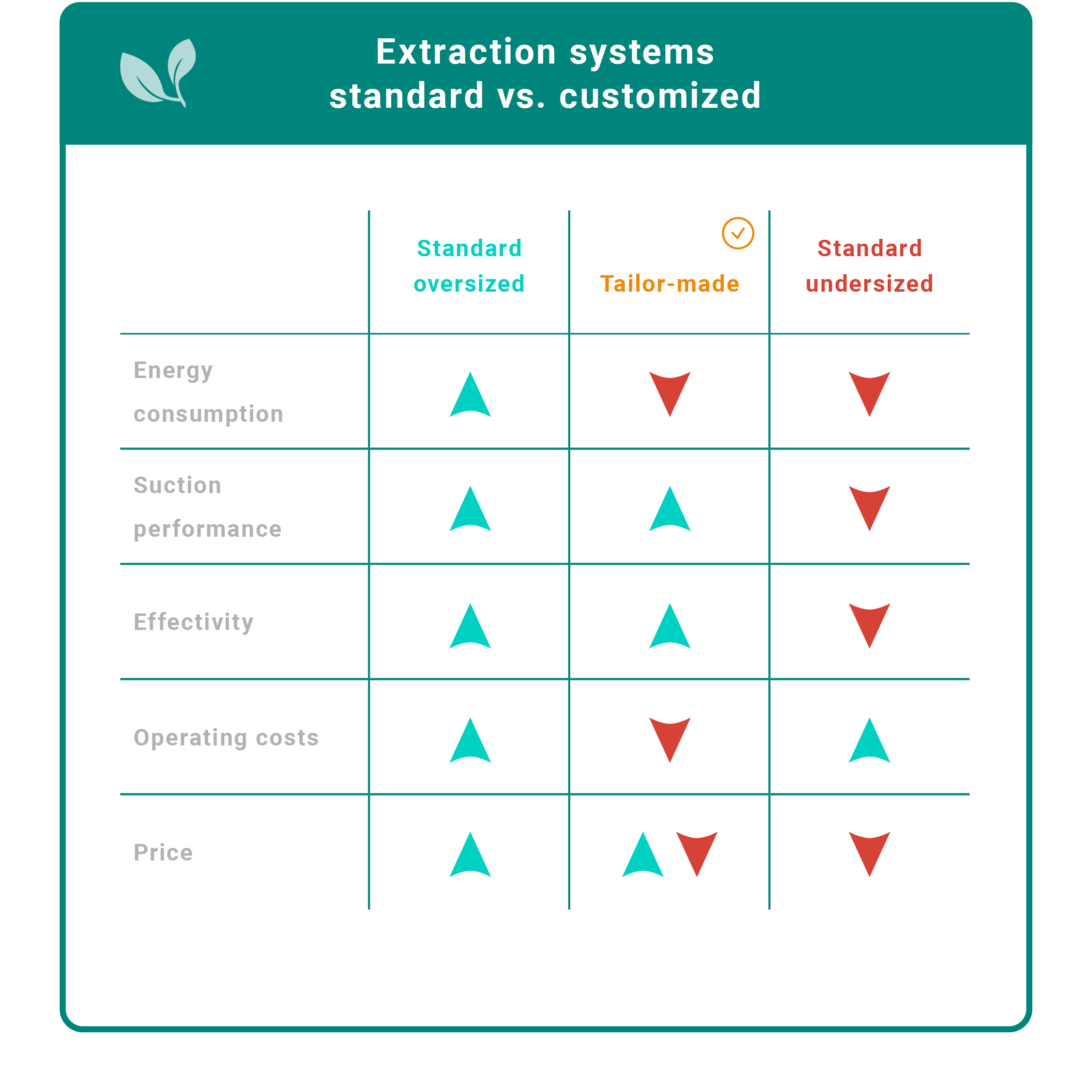

Standard vs. customized in the industry

Where the standard ends, we start with our customized extraction systems. These are developed, designed and produced in our own factory. With our know-how and numerous configuration options, we adapt our extraction systems to the respective application and thus deliver systems that are as efficient as possible in terms of performance, energy consumption and quality.

Where the standard ends, we begin!

- Construction and technical design inhouse

- Numerous configuration options

- Long filter service life

- Process-optimized extraction systems

- Constantly high performance without loss of energy

- Extendable and future-proof

- Low-maintenance extraction systems

- 360° service including pipe planning and assembly

- For every industry and every use case

- Qualität made in Germany

Individual extraction systems

Our broad product portfolio ranges from deduster, fume filter and wet separators to filter towers and extraction tables for a wide variety of industrial processes. We offer individual extraction solutions and suitable pipe systems for almost every area of application in manufacturing plants.