Extraction arms

Extraction arms for welding, grinding and other processes

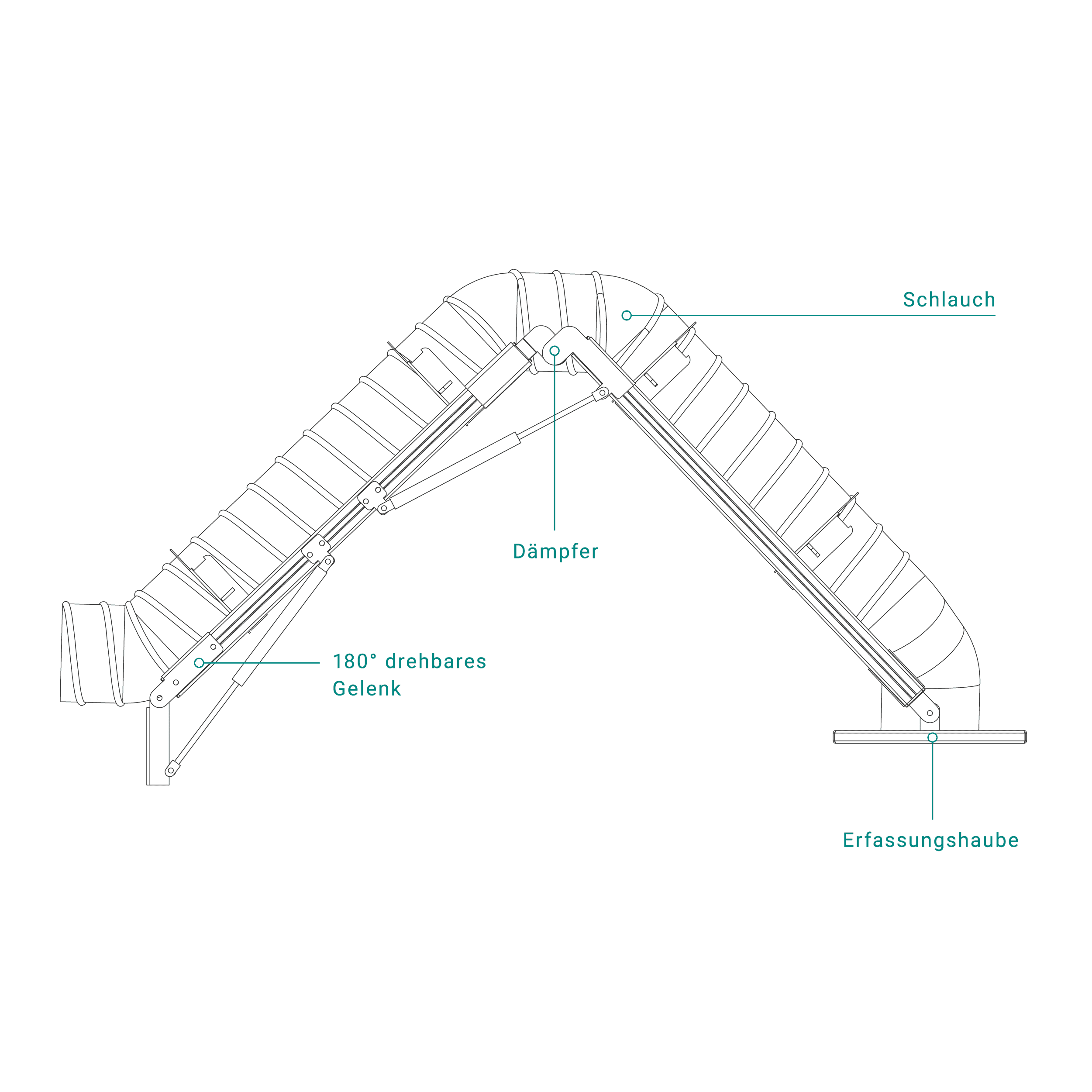

Extraction arms serve as a capture element and are connected to an extraction system or a pipe system and capture emissions such as fumes, welding fumes and dust directly at the point of origin. Due to the flow-optimized design and low resistance in the extraction arm, they are also suitable for continuous shift operation.

Spot extraction using extraction arms

-

Fast adjustment possibilities

-

Special captures for each process

-

Maximum extraction power

-

No deposits

-

No pressure loss

-

Low cleaning effort

-

Easy installation

MEDIA

Dust, smoke, vapor, oil mist, emulsion, soldering fumes, aerosols

PROCESSES

Welding, grinding, polishing, sawing, cutting, separating, turning, milling, flexing, lasering

APPLICATION

Single-user solution

Multi-user solution

Hall ventilation

Flexible extraction arms – ergonomic and efficient

Maximum efficiency and easy handling ensure a safe and ergonomic workplace. We use our technical expertise to design flow-optimized extraction arms and other collection systems, which are available in numerous options. Low resistance and smooth inner surfaces ensure consistently high extraction power and minimal cleaning effort for our extraction arms.

Extraction arms in ATEX design are completely electrically conductive and suitable for the selective extraction of explosive dusts and gases (according to ATEX Directive 2014/34/EU). All extraction arms are delivered fully assembled and tested.

Smooth-running suction arm with PVC hose

and plastic hood with handle

Solid extraction arm with aluminum tube

with energy saving throttle valve

Solid extraction arm with aluminum tube

in ATEX design

Individual configuration of extraction arms

The joints with light guidance offer maximum flexibility and a large radius of action. The extraction arm can be guided into the correct working position with just one hand and is held there permanently. The adjustable hoods reduce tracking and make alignment even more precise. As every process and the material to be processed has different requirements, we offer our extraction arms in all standard diameters, various lengths and (2–9 meters)hoods, hose or pipe in various designs.

Options & variants extraction arms

LIGHTING

Perfect working light

START BUTTON

Position on extraction hood

VARIOUS CONSTRUCTION

Individual as desired

EXPLOSION PROTECTION

ATEX execution

360° WORKING RADIUS

Optimal setting

VARIOUS ACQUISITIONS

Funnel hood, flat hood, Coanda hood and much more

PU HOSE

High flexibility

SOLID PIPE

Steel or aluminum

CANTILEVER

Practical extension

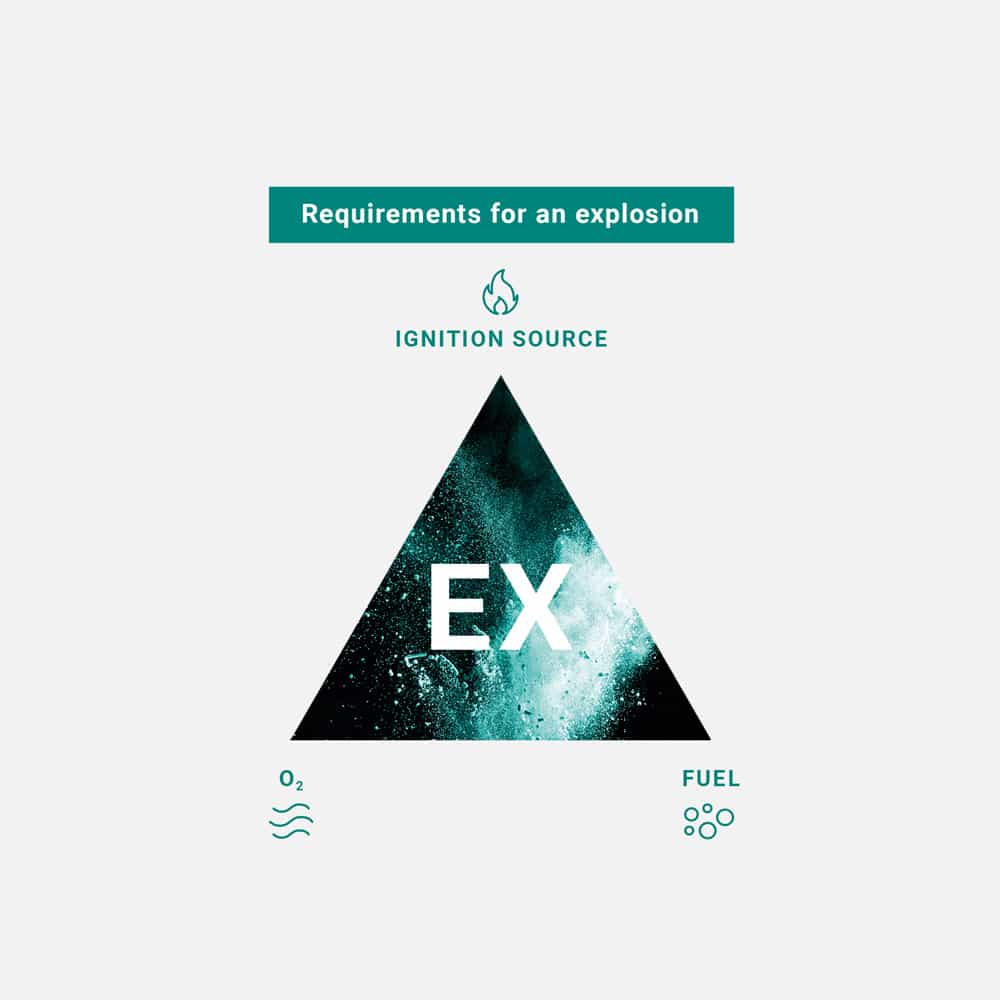

Fire and explosion protection

at ABSAUGWERK

Flammable and explosive media such as gas, steam, mist or dust can cause serious fires and violent explosions. Our extraction arms are therefore equipped with special fire and explosion protection components and offer safe operation:

- Flow-optimized design

- No deposits

- External joints

- ATEX execution (electrically conductive)

Fast installation

For our extraction arms, we offer versatile connections such as fans, central or mobile extraction systems, filter units, pipe systems or hall ventilation systems. However, the arms can also be easily attached to existing systems and are thus quickly ready for use We offer a wide range of mounting options for our extraction arms:

- Ceiling mount

- Floor mounting

- Wall mounting

- Extraction slot channel (various versions)

- Connection to extraction or pipe systems