ATEX extraction systems

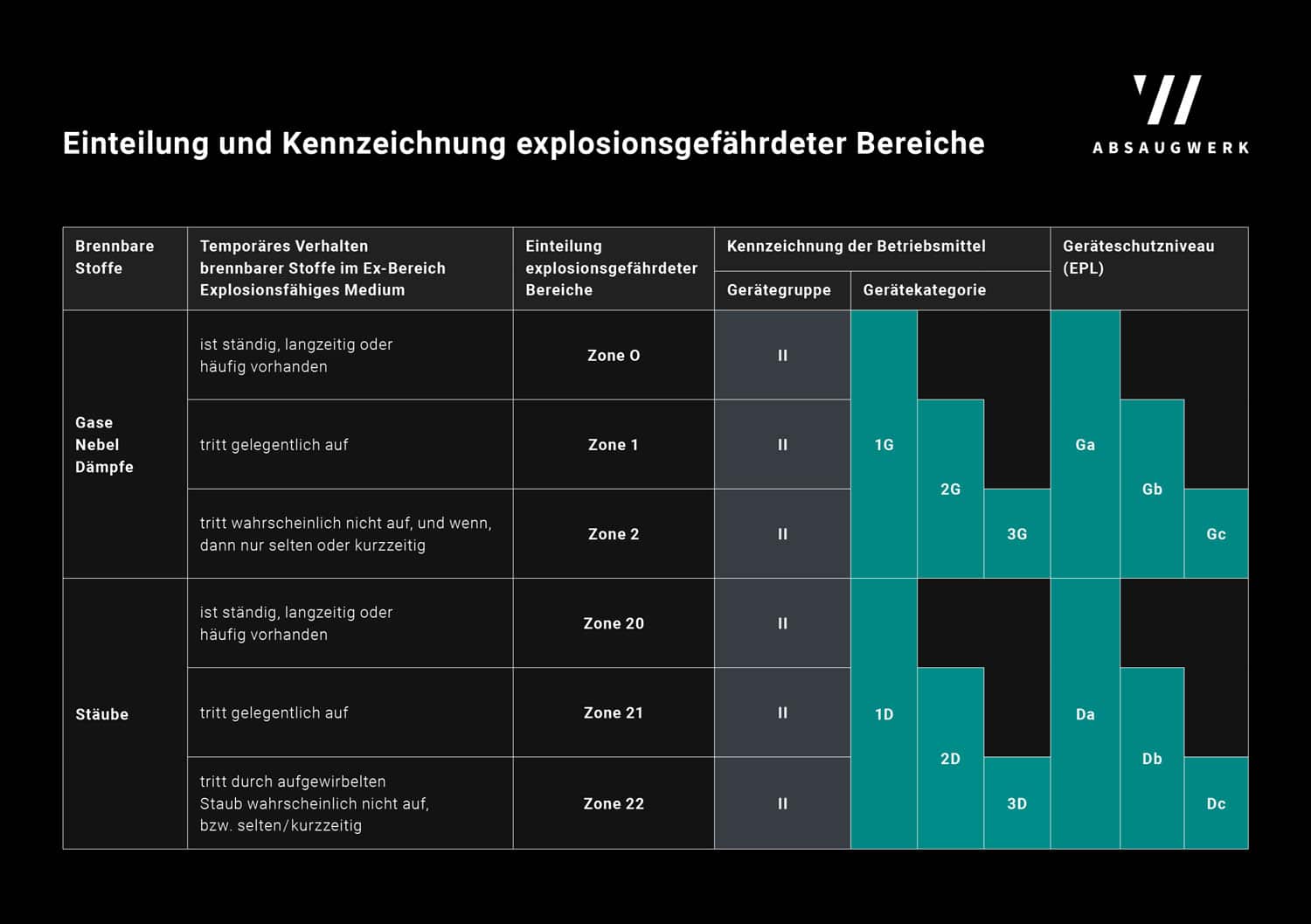

In many business and industrial sectors, flammable and explosive media are released during production processes, which can trigger serious fires and violent explosions due to chemical reactions. This can injure people, destroy buildings and plant components, and ignite other flammable substances.

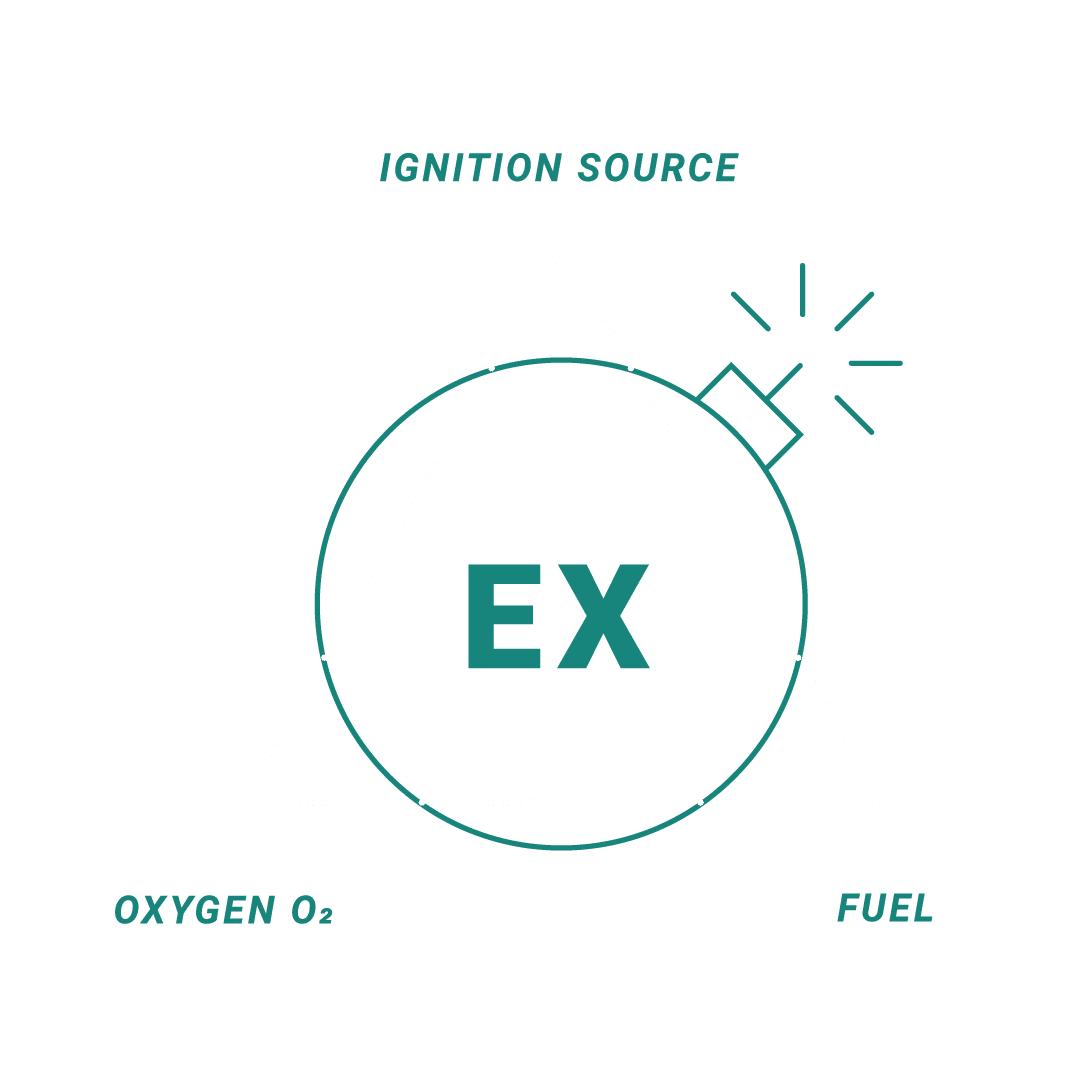

Requirements for an explosion

The combination of oxygen, explosive dusts and an ignition source can cause severe explosions.

Possible ignition sources:

- Spark/flame

- Discharge of static electricity

- Electrical malfunctions

- Hot surfaces

- Grinding/friction sparks

Explosion protection technology from ABSAUGWERK

The design principle of our systems is based on primary explosion protection, which preventively avoids the formation of explosive atmospheres. This is achieved through maximum separation efficiency, high air velocities and ATEX-compliant components. We use various ATEX components and an innovative design to ensure the safe operation of our systems.

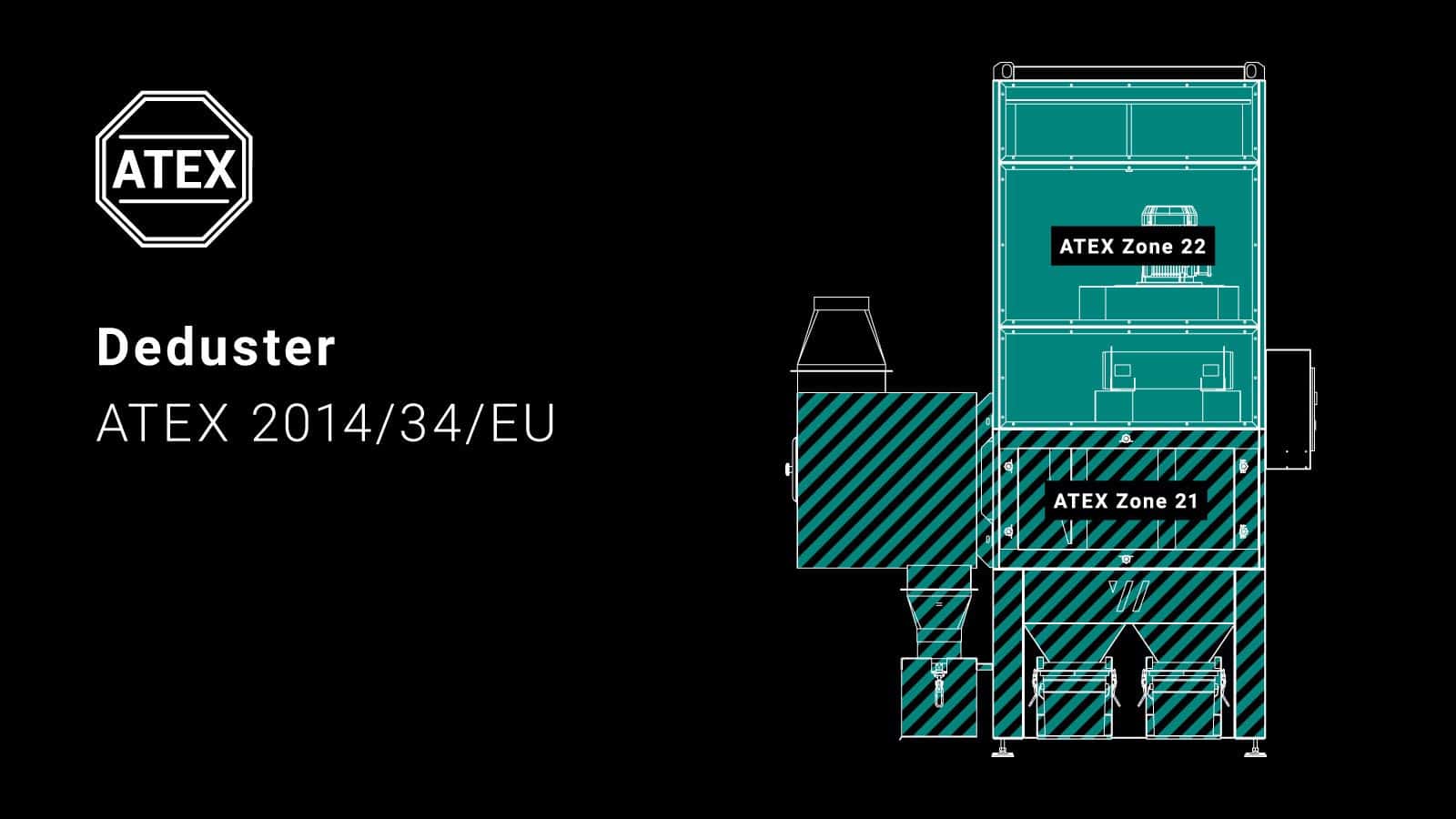

ATEX components dry extraction

- Pre-separator

- Spark detection

- Automatic extinguishing systems according to DIN/EN: water, powder, CO₂

- Air speed in the pipe min. > > 20 m/s

- Automatic shutdown of the system

- Negative pressure and volume flow monitoring

- Motor according to ATEX Zone 22

- Painted impellers

- Construction free of ignition sources and conductive

- No Ex-zones during operation

- All electronic components installed in conformity with ATEX

- Control cabinet outside the plant (no Ex-zone)

- Precoat unit (filter coating)

- Automatic jet pulse cleaning (offline)

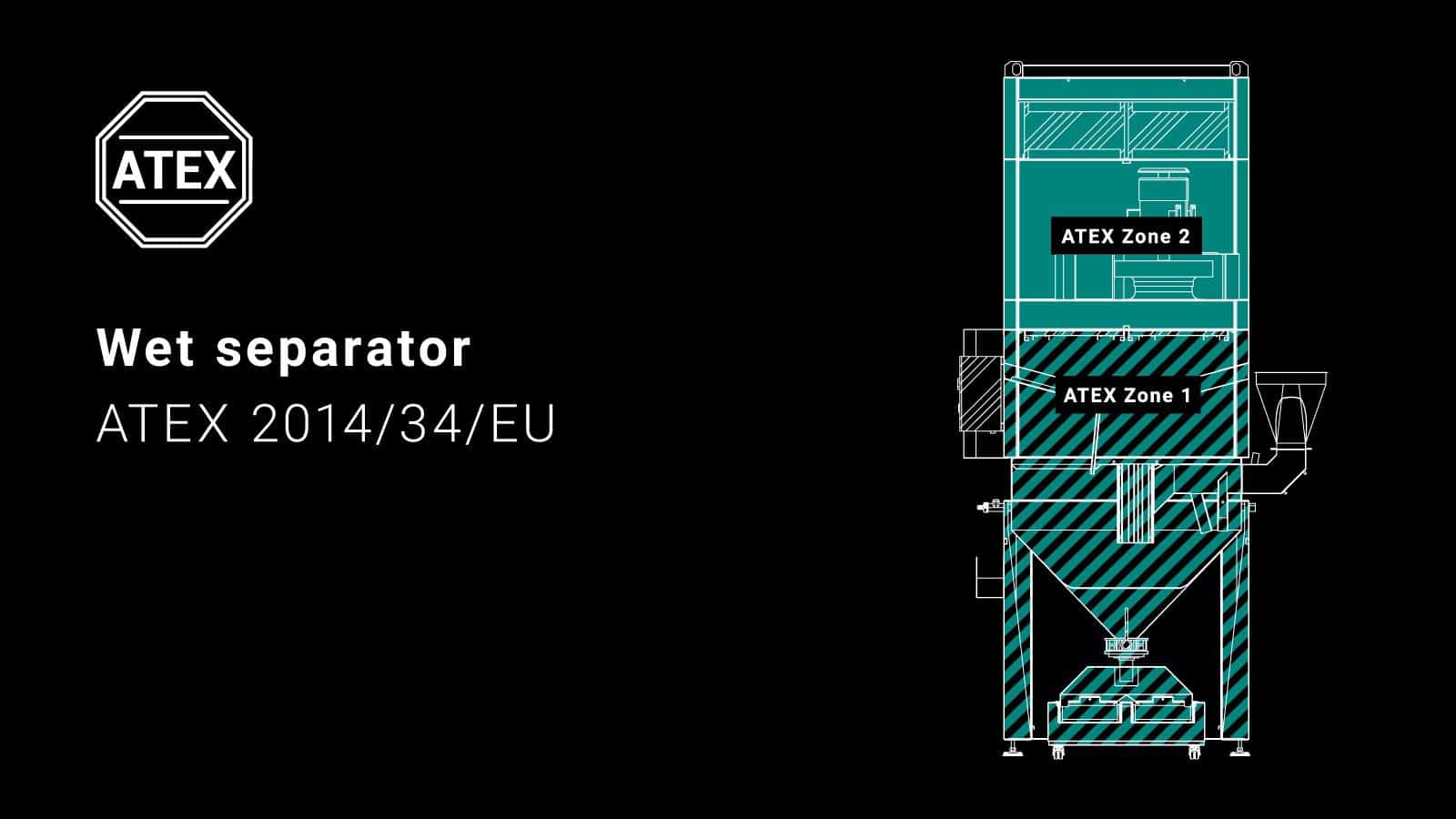

ATEX components wet extraction

- Air speed in the pipe min. > > 20 m/s

- Automatic shutdown of the system

- Negative pressure and volume flow monitoring

- Motor according to ATEX Zone 2

- Painted impellers

- Construction free of ignition sources and conductive

- No Ex-zones during operation

- All electrical components installed in conformity with ATEX

- Control cabinet outside the plant (no Ex-zone)

Legal requirements

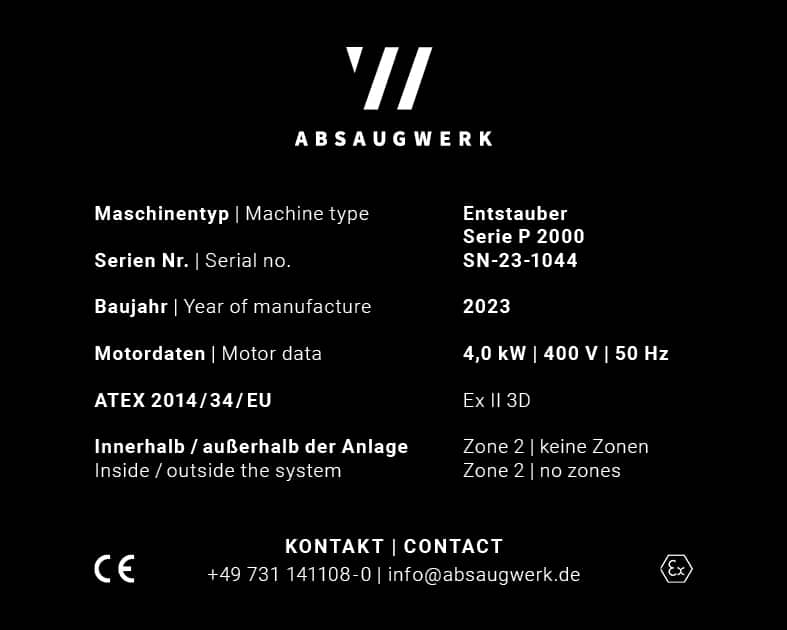

Within the European Union, all aspects and specifics of explosion protection are listed in the so-called ATEX directives. The directives distinguish between manufacturers and operators and must be observed by both parties in order to ensure safe operation and to comply with occupational health and safety. When designing our extraction systems, we include all relevant parameters, evaluate them according to legal regulations and thus manufacture ATEX-compliant systems for every application.

Your advantages

Savings

up to 50%

Low operating

and follow-up costs

Maximum

extraction power

Maximum

separation efficiency

Safe operation with

highest quality standard

Installation in

interior possible

Mixed operation

aluminum & stainless steel

When processing stainless steel and aluminum, chemical reactions produce self-igniting and highly carcinogenic dust mixtures. We have developed a special deduster that reliably extracts and filters both substances even in mixed operation.