WET EXTRACTION

BasicsWet extraction in industry

Both dry separators and wet separators are suitable for separating and filtering dust or chips from the air. Which extraction system is optimal for your application depends on various factors: Process, medium, installation site as well as specific regulations for fire and explosion protection.

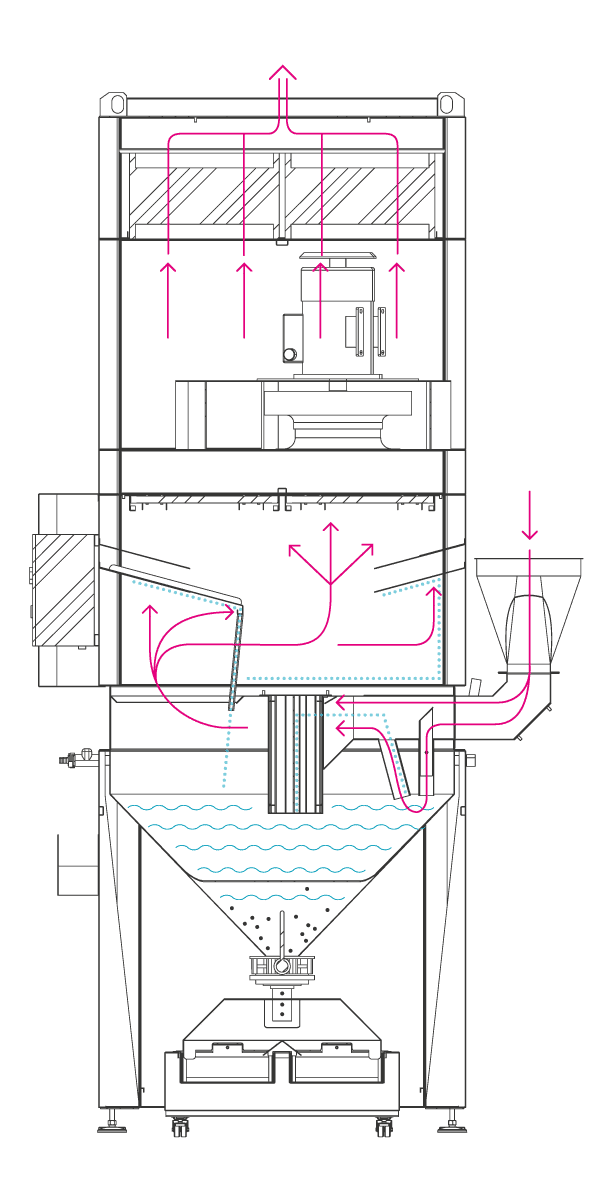

Functionality wet separator

In addition to dry dust extractors and smoke filters, wet separators are often used in industrial exhaust air purification. While dry extraction systems clean the air containing dust via several filter levels, wet separators use water to filter the substances out of the air.

The contaminated process air is drawn through either a water basin, a water wall or a water vortex. The particles are bound in the water by this technique and any remaining fine dust is separated in a HEPA H14 filter. The cleaned air can then be fed back into the hall or outside. Instead of dry dust, industrial sludge remains here as so-called discharge, which must be disposed of in accordance with regulations.

Efficient disposal of sludge discharge

Due to the innovative design of our sludge containers, the water is separated from the sludge by a sieve and can be fed back into the wet separator via an optional feed pump. This reduces water and disposal costs many times over and protects the environment. On average, up to 5,200 L of water can be saved per year. The remaining sludge can be disposed of more economically in accordance with local regulations.

Water recovery = less water, less costs, more environmental protection.

Dry extraction or wet extraction?

Whether a wet separator or dry dust extractor is suitable for your application depends on the nature of the material, the quantity and the physical properties.

Pros and cons

Wet extraction

-

Minimal fire risk

-

Inexpensive purchase

-

Low filter wear

-

Ideal for sticky, sparking

and wet materials

-

Higher cleaning and maintenance effort

-

Outdoor installation not possible

due to danger of freezing -

Higher disposal costs

of the discharge

Areas of application

Wet separators or wet scrubbers are particularly suitable for processes and substances that are associated with high levels of flying sparks, are sticky, moist, flammable or explosive (ATEX regulations). Grinding, deburring or sawing aluminum releases dusts and chips that must be safely extracted and filtered to comply with occupational health and safety regulations and environmental protection.

This process is also called wet dedusting and is used in a wide variety of sectors such as the automotive industry, mechanical engineering, the food industry or other metalworking companies.

INDUSTRIES

- Metalworking

- Food

- Stone and earth

- Pharmacy

- Recycling

- Plastics

- Automotive

PROCESSES

- grinding, polishing

- Sawing, cutting, separating

- Machining, milling

- Decanting, filling, mixing

MEDIA

- Flammable and/or explosive dusts

- Dusts of aluminum, magnesium, steel, titanium

- Wet or sticky dusts

- Leather, rubber and plastic abrasion

- Fibers, lint, textile dusts

- Chips

Wet separator for aluminum dust

Machining aluminum can produce an explosive dust-air mixture. Wet separators offer a safe and reliable extraction solution for aluminum, stainless steel and other metals through the technical use of water.

FAQs

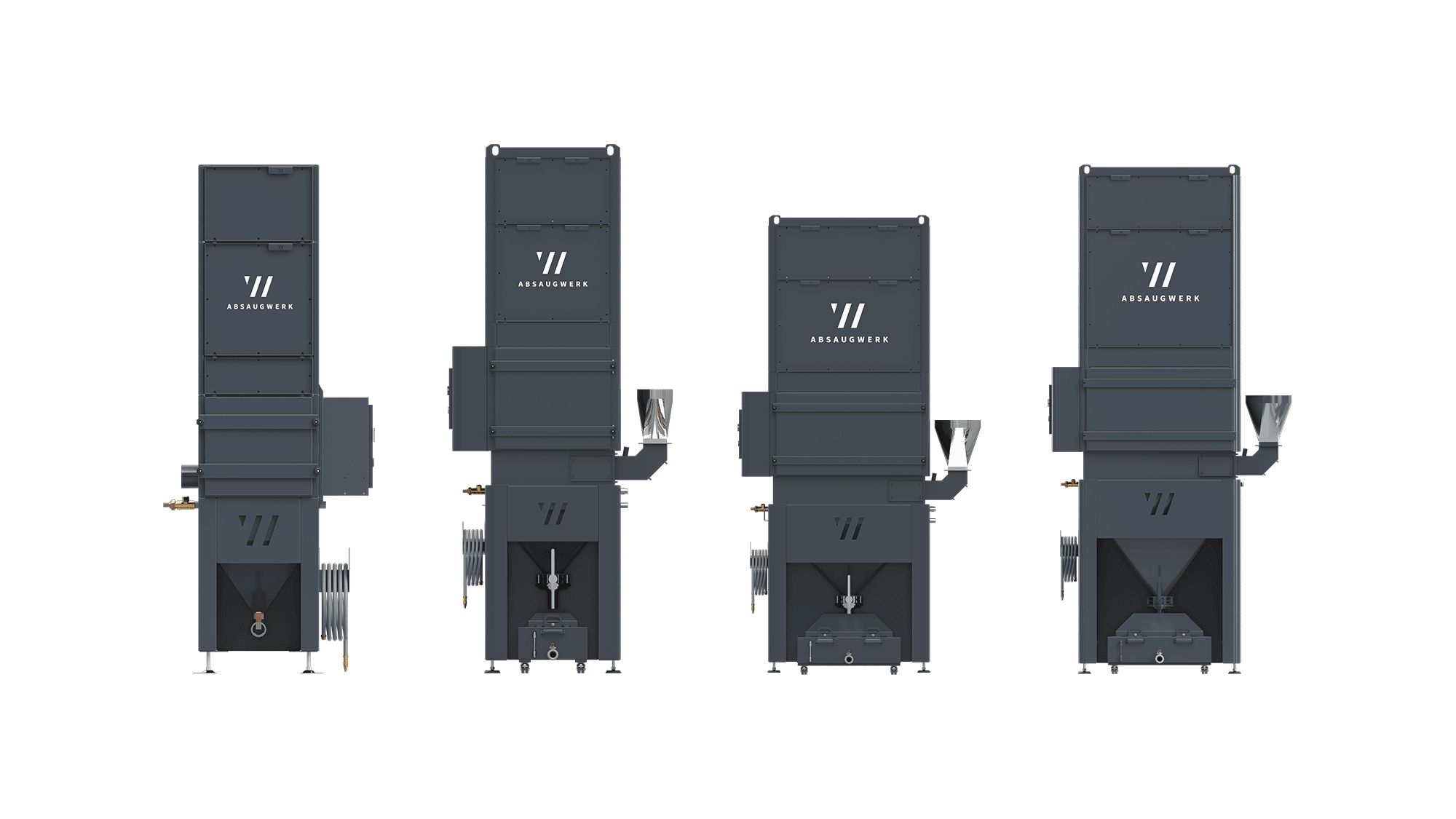

Wet separators from ABSAUGWERK

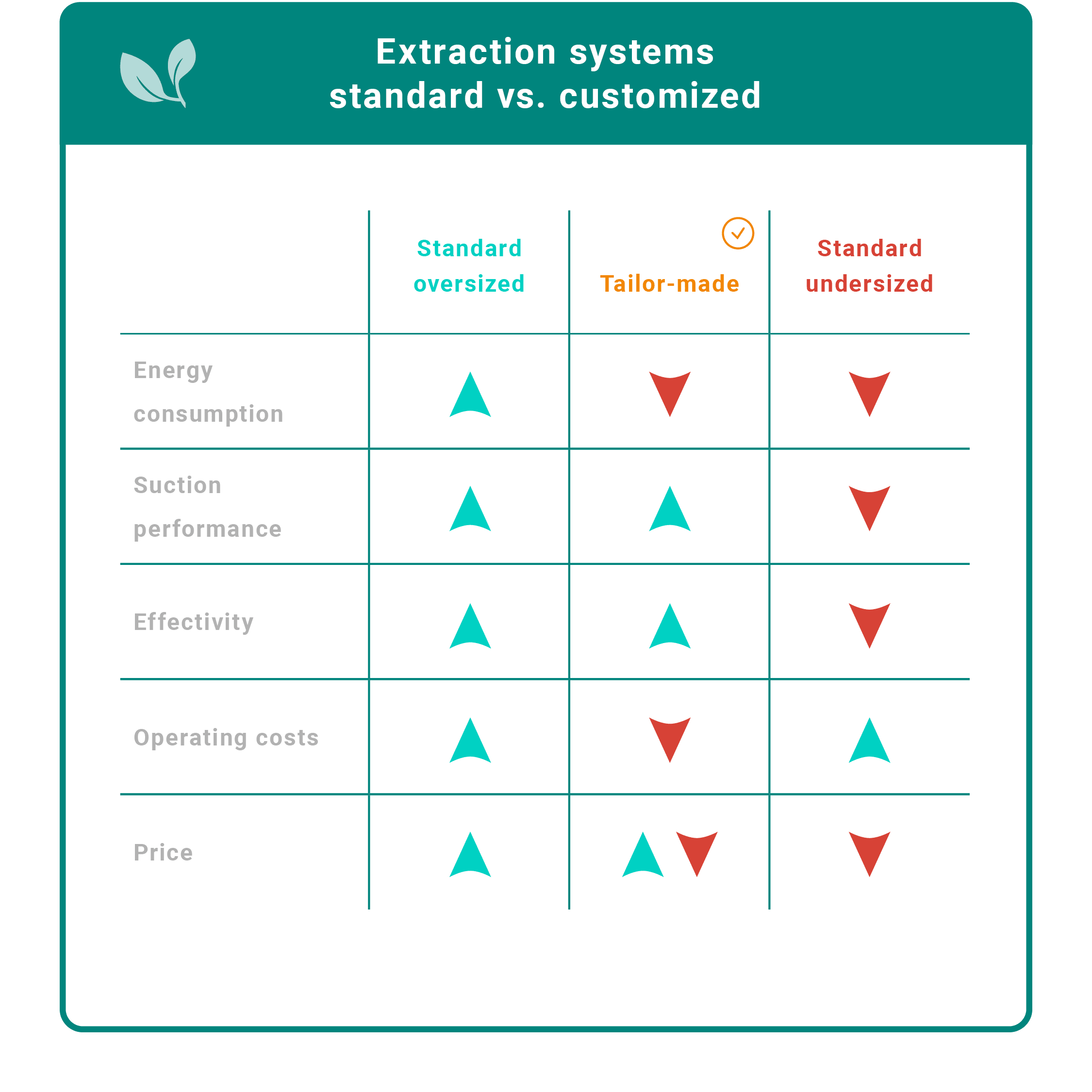

Every application is unique. Therefore, wet separators from ABSAUGWERK are available in various sizes and designs. With versatile options, we plan our extraction systems tailor-made and optimally adapted to your processes and materials. This way we can guarantee you an economical investment and deliver an effective extraction solution.

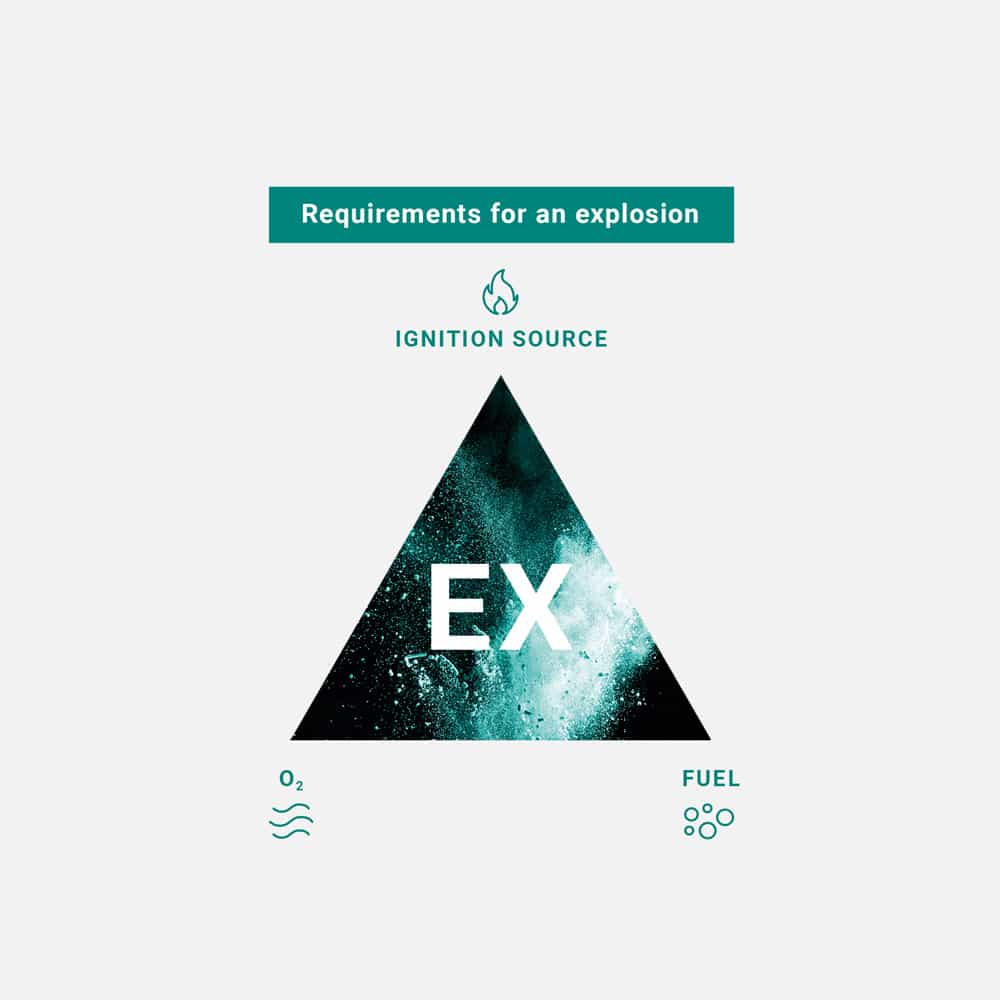

Explosion protection according to ATEX for wet separators

In the right mixing ratio with oxygen and an effective ignition source, flammable and explosive media in the form of gas, vapor, mist or dust can cause serious fires and violent explosions. This can injure people, destroy buildings and plant components, and ignite other flammable substances.

For this reason, so-called ATEX directives (ATmosphères EXplosibles) apply to industrial extraction systems.

Better for people and the environment

50%

MORE

EXTRACTION POWER

30%

LOWER ENERGY COSTS

IN THE YEAR

25%

MORE

FILTER AREA

20%

LESS WATER CONSUMPTION

IN THE YEAR

Clean air in production halls promotes the health of employees, makes workplaces safer and protects the environment. At the same time, machinery, tools and workpieces are protected and their service life is significantly extended.

When developing our wet separators, we paid special attention to low operating costs, high energy efficiency and low follow-up costs. For example, our metal mesh filters are easy to clean with a conventional high-pressure cleaner. In contrast to standard systems, our individual extraction systems consume only the amount of electricity, air and water that is actually needed. In addition, the cleaned air, which is still warm, can be returned to the hall through recirculation operation. This saves enormous energy costs, especially in winter.

Customized extraction systems for maximum efficiency and economy