GRAMMER

Grinding and polishing in the automotive industryGRAMMER

Grinding and polishing in the automotive industry

Grammer AG is one of the world’s leading suppliers of driver and passenger seats for commercial vehicles, trucks, buses and trains. In the automotive sector, Grammer supplies well-known car manufacturers and system suppliers to the automotive industry. The original saddlery was founded back in 1880 and has grown to become a global company with 14,000 employees in 19 countries.

For the final processing of glass panels for a German car manufacturer, a dust mixture of fluff, polishing paste and glass is released during the polishing process. Glass dust has carcinogenic properties that can endanger the health of employees in the vicinity. It was therefore important to find a solution that effectively protects against these dusts.

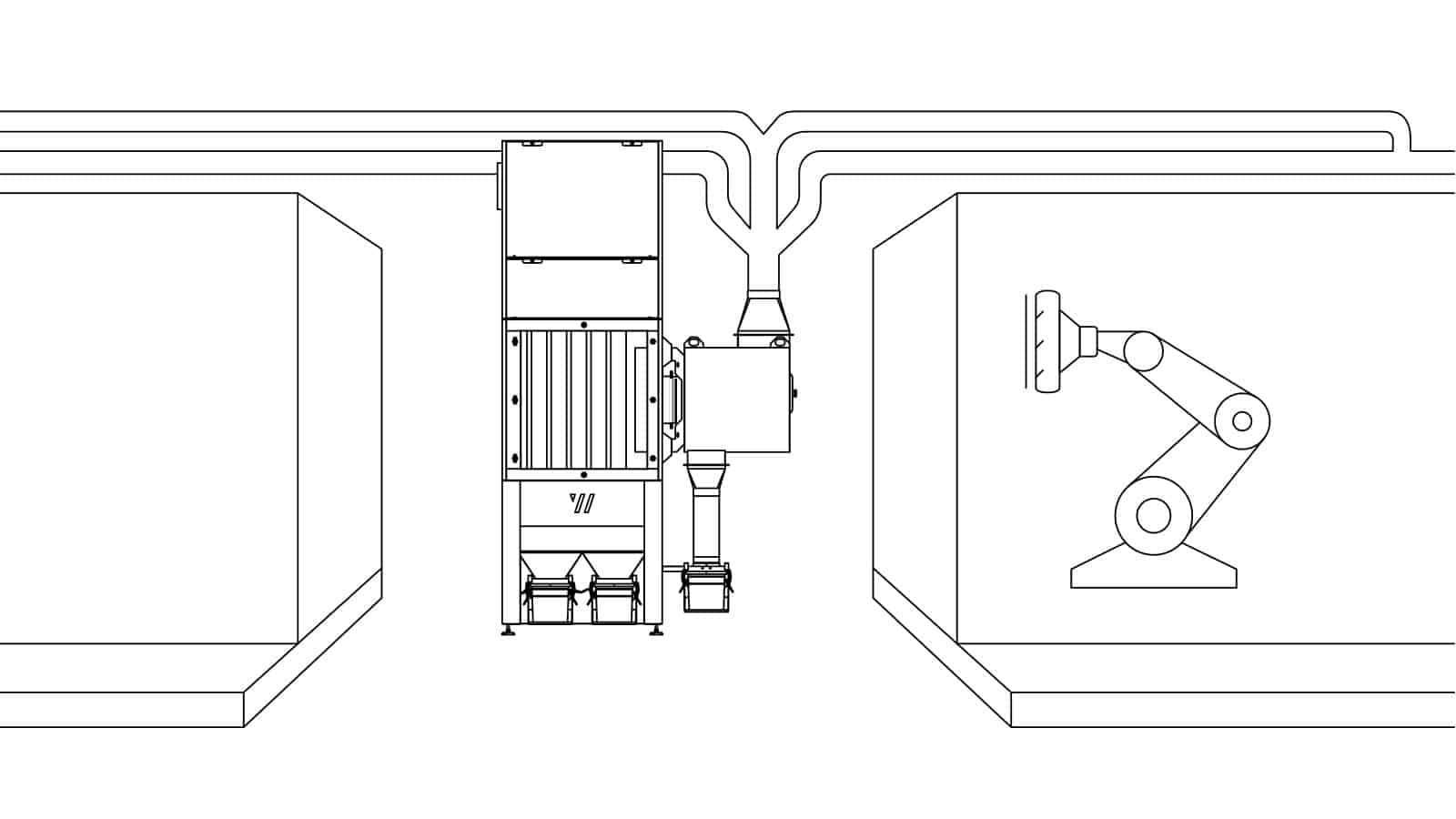

Two separate work booths were set up specifically for robot grinding and equipped with suitable protective measures to minimize employee exposure to the dust.

INDUSTRY

automotive

PROCESSES

Grinding

Polishing

MEDIA

Lints

Glass

Polishing compound

Requirement:

- 2 sanding cabins with extraction hoods

- Filtering the cabin air using an extraction system

- Reliable protection against carcinogenic dusts

- Compliance with applicable workplace regulations

- Reliable filtering of 3 types of dust: lint, glass, polishing paste

- Longest possible filter service life

- Smooth 3-shift operation

Our extraction solution:

Robot grinding in 2 cabins

The dust is collected by 3 extraction hoods in the two sanding booths and filtered by a deduster. A pre-separator removes coarse particles and sparks before the air is cleaned by two further filter stages.

Special HEPA H14 filters are used for the fine, carcinogenic glass dust. The cleaned air is then fed back into the hall in energy-saving recirculation mode.

Long life filters

48 antistatic bag filters are ideally suited for continuous operation in 3 shifts. A pre-separator renders sparks harmless and protects the filters from damage caused by coarse particles or chips.

The automatic Jet-Pulse filter cleaning maximizes service life.

Fire and explosion protection

The multi-stage fire protection concept includes a special filter coating, wireless sensors and a powder extinguishing system, thus meeting the highest technical standards in accordance with DIN norms.

Glass dust is not only carcinogenic, but also highly flammable and explosive. The use of a dust extractor therefore requires special explosion protection components in accordance with the statutory ATEX directives.

Result:

✓ 1 deduster, 3 types of dust

The dust mixture of carcinogenic glass dust, fluff and sticky polishing paste is separated from the air via various filter stages without clogging the filters.

✓ Long filter service life

The high-quality permanent filters and the measures for filter protection and filter cleaning protect the filters and increase their service life. This reduces operating costs.

✓ Trouble-free operation

The smooth 3-shift operation and long filter service life prevent downtimes and reduce operating costs. Fires and explosions are effectively prevented over several stages.

We support our customers from A to Z: personal advice, technical design, planning of the pipe system, production, installation, piping, commissioning, maintenance and after-sales.

TECHNICAL DATA

- Work areas: 2 extraction cabins

- Systems: Deduster S series 4000

- Performance: 7.5 kW

- Max. Air volume: 8,500 m³/h

- Operating point: 3,700 m³/h

- Air flow: Recirculated air

- Installation: Indoor area

- Filter: Bag filter, HEPA H14 filter incl. monitoring

- Control system: Siemens LOGO! 8 with frequency inverter

- Detection: Pneumatic gate valve

- Discharge: Deduster 15 L

- Pipe system: 30 m longitudinal seam pipe, 3 m spiral seam pipe

- ATEX execution

- Fire protection with powder extinguishing system

- Sound insulation

ADVANTAGES AT A GLANCE

- Filter protection and filter cleaning

- Long filter service lifetime

- Low resistance in unit and piping system

- High extraction power

- Low energy consumption

- Low operating costs

- Quiet operation thanks to innovative sound insulation concept

- Development and assembly directly from the manufacturer

ABSAUGWERK offers first-class extraction solutions for the manufacturing industry that protect people, machines and the environment. We are proud to make workplaces safer and cleaner with our systems. In this way, we actively contribute to the protection of employees, extend the service life of machinery and reduce the environmental impact.