REISCH FAHRZEUGBAU

Creative welding fumes extractionREISCH FAHRZEUGBAU

Creative welding fumes extractionAt Reisch Eliasbrunn GmbH, welding, laser cutting, sandblasting and bolting are carried out. With a production area of 40,000m² and 250 employees, the company produces up to 168,500 vehicles a year. Reliability and consistently high weld seam quality have top priority in demanding welding processes for large assemblies in the agricultural and commercial vehicle sector.

When investing in a turnkey welding system from Valk Welding with an integrated extraction system, Reisch Eliasbrunn GmbH was looking for a flexible partner like ABSAUGWERK. We developed a customized solution for two combinable welding robots despite the low ceiling height.

INDUSTRY

Vehicle construction

PROCESSES

Welding

MEDIA

Welding fumes

Requirement:

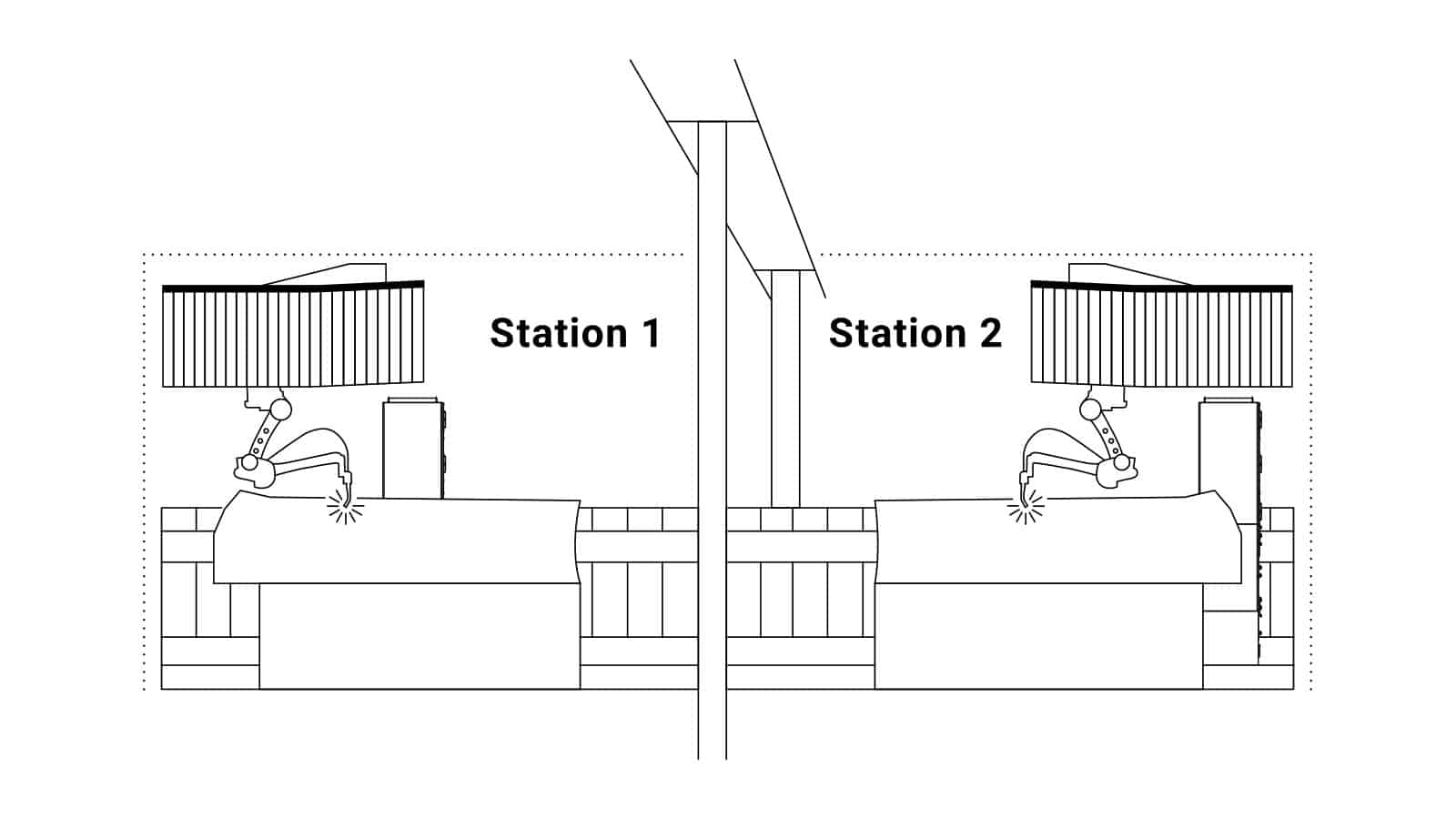

- Welding fume extraction for two combinable welding robots from Valk Welding

- Mounting on robot slides

- Low ceiling height

- Smoke capture via very large extraction hoods

Our extraction solution:

Creative welding fume detection

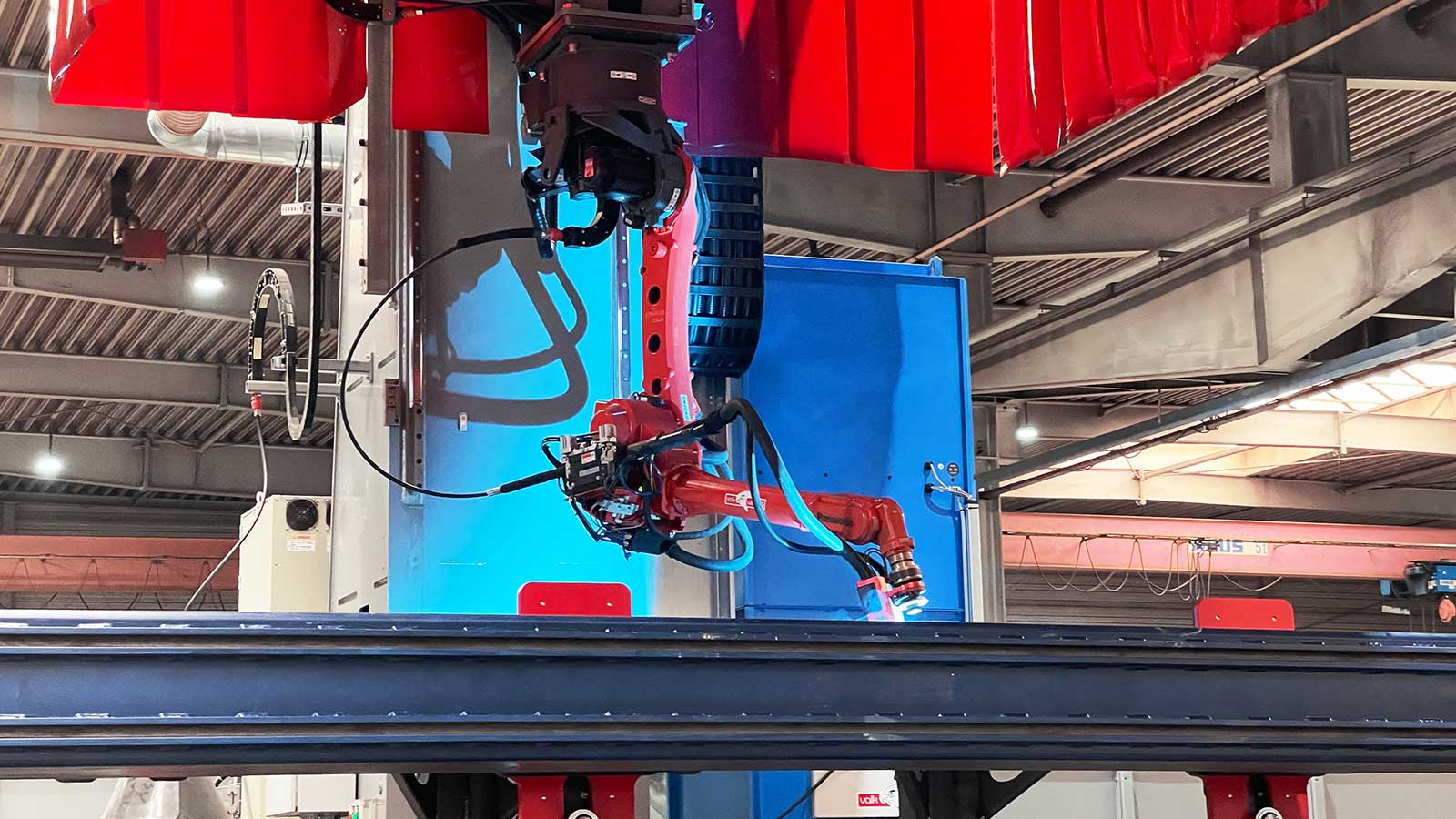

Two welding fume filters each extract the harmful fumes via an extraction hood. The extraction systems, welding robots and hoods were mounted on the mobile carriages. The piping had to be flexible and was supplemented with expandable hose elements.

Weight Watchers

Despite the high suction line, the two smoke filters were designed to be particularly light in order to keep the motor power and energy costs of the carriages low.

The footprint of the system was reduced to the available space.

Capture with power

The extraction hoods from Valk Welding are height-adjustable and require large diameters for optimum fume capture. The extraction systems achieve high extraction capacities of up to 6,000 m³/h despite their low weight and small footprint.

Result:

✓ Individual extraction solution

Thanks to the individual planning, all requirements and restrictions could be met without expensive compromises.

✓ Safe working area

The fine smoke particles are filtered efficiently and protect all employees in the hall. Occupational health and safety requirements are met and air quality is improved.

✓ Space-saving

The welding fume filters could be mounted on the carriage and do not take up a centimeter of space on the production floor.

We were pleasantly surprised by the extraction power!

»We were surprised that the extraction...We were pleasantly surprised by the extraction power!

»We were surprised that the extraction works so well in terms of air volume and that the flue gases are extracted upwards accordingly.«

We support our customers from A to Z: personal advice, technical design, planning of the pipe system, production, installation, piping, commissioning, maintenance and after-sales.

TECHNICAL DATA

- System: 2 fume filters series R 2000

- Power: 4 kW

- Max. Air volume: 6,000 m³/h

- Air flow: Recirculated air

- Installation: Indoor area

- Filter: Cartridge filter, HEPA H14 filter

- Control system: Siemens LOGO! 8

- Acquisition: Extraction hoods

- Discharge: Deduster 15 L

ADVANTAGES AT A GLANCE

-

- High extraction power

- Low energy consumption

- Suitable for low hall ceilings

- Low space requirement

- Filter cleaning for longer service life

- Low wear

- Low operating costs

ABSAUGWERK offers first-class extraction solutions for the manufacturing industry that protect people, machines and the environment. We are proud to make workplaces safer and cleaner with our systems. In this way, we actively contribute to the protection of employees, extend the service life of machinery and reduce the environmental impact.