PRECOAT-UNIT

Precoat units for extraction systems

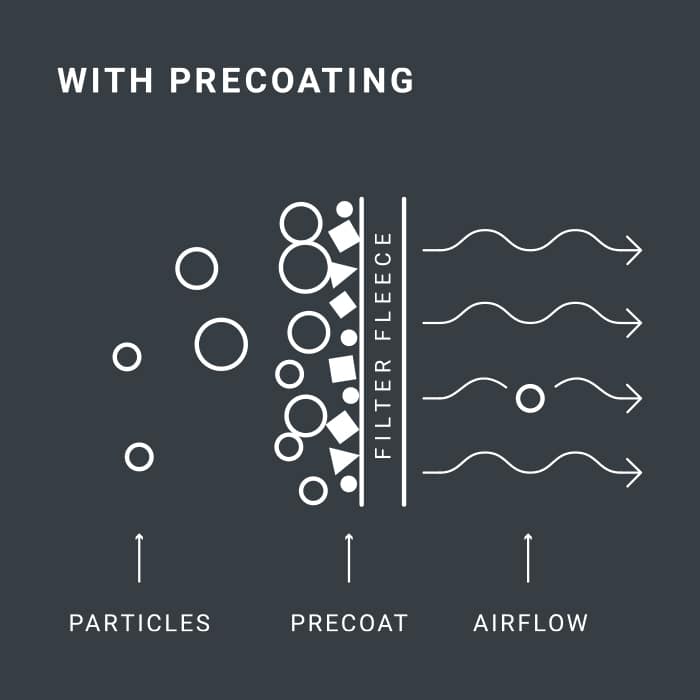

The use of precoat units increases filter performance many times over, reduces the risk of fire and extends filter change intervals. Precoat units are directly connected to the respective extraction unit and apply the filters fully automatically.

Filter protection and efficiency

through precoat powder

In order to extend the service life and effectiveness of filters in extraction systems, precoat units are often used, which periodically coat the filters with limestone powder or other precoating agents (so-called filter aids). Sticky, oily and moist media can thus not immediately stick to the filter material and filter cleaning is significantly improved.

-

Maximizing filter performance

-

Fully automatic operation and dosing

-

Lower fire risk

-

Longer filter service life

-

Sustainable

-

For sticky, oily and moist media

-

Easy to retrofit

Processes

Lasering

Cutting

Plasma cutting

Laser cutting

Welding

MEDIA

Moist particles

Lubricating particles

Oily particles

Welding fumes

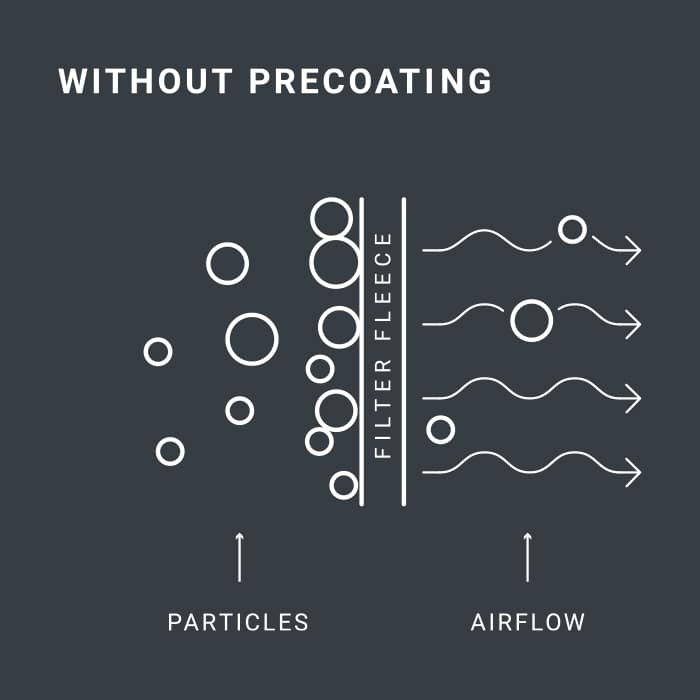

Without vs. with precoating

Due to the artificial dust layer of the precoat powder, dust and smoke particles are deposited on the precoat layer. The air flow passes through the filters and the filter medium is protected from sticky substances that can clog and stick to the filter fleece. Furthermore, the filter performance increases and a higher filtration efficiency can be achieved.

Dosage & Monitoring

Filter aid

If the dosage of the filter aid is not correct, this can impair the effectiveness of the filter performance and fire protection or render it ineffective. Therefore, we double-proof the dosing and additionally monitor the air flow in the unit.

Filter cleaning

The precoating agent is blown off the filters together with the dust and smoke particles via the automatic jet pulse cleaning system and ends up in the discharge container of the extraction unit.

Filter aid

Limestone powder, slaked lime (carcinogenic) or aluminum silicate can be used as filter aids. They serve as particle filters for sticky, oily dusts and coarser particles that could damage or stick to the filter fleece. All ASBAUGWERK precoat units work with limestone powder, as this is harmless to health and efficient. The correct dosage is crucial: If the mixing ratio is not correct, the fire protection becomes inactive, the filters stick together or clog aprubtly. Therefore, the dosing is monitored twice and an accurate dosing unit is used.

Safe operation

- Exact dosing

- One to three extraction hoods for filling

- Contact switch on system cover

- 2-fold monitoring of the dosing

- No bridging, clogging, sticking

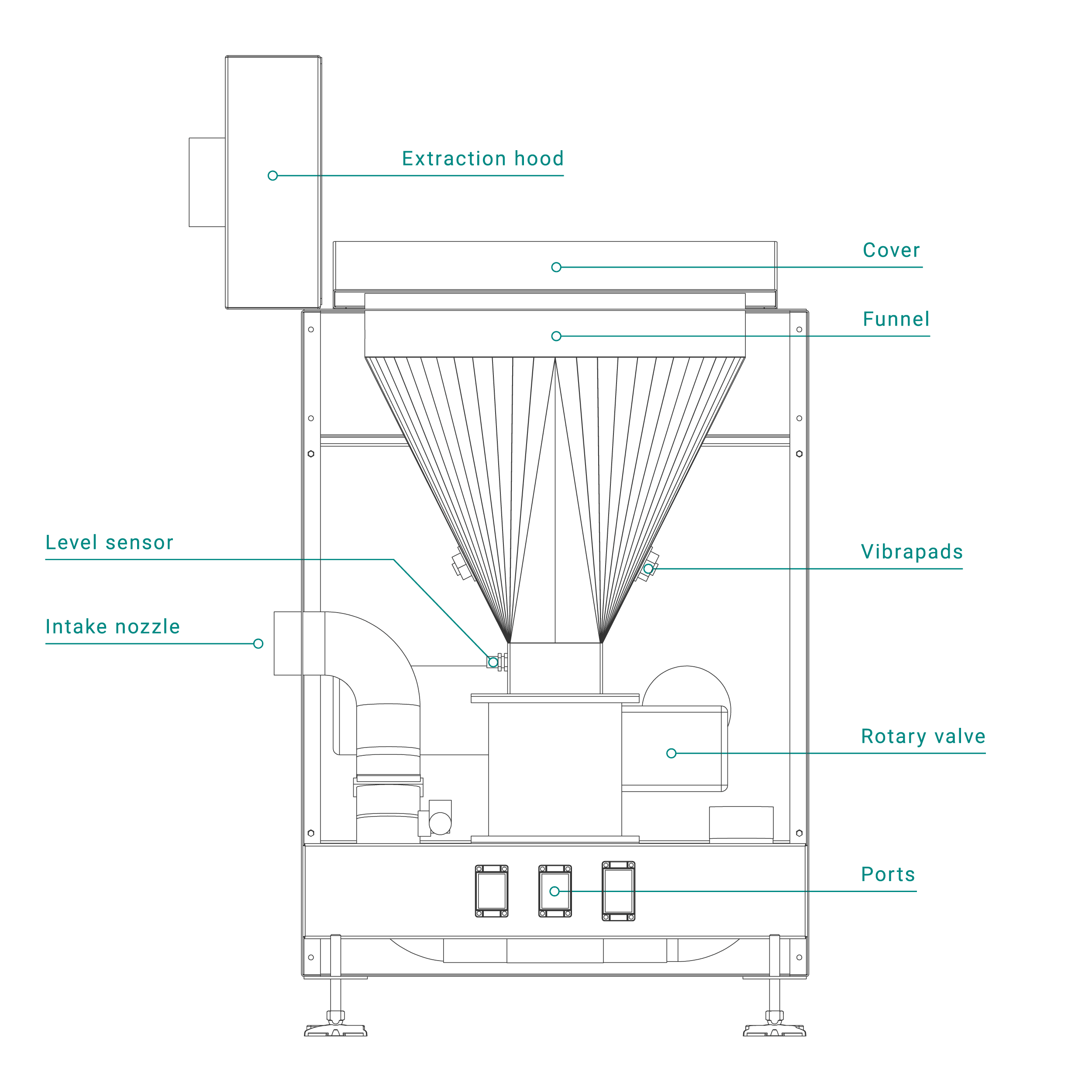

Technical data

- Motor power: 0,37 kW

- Footprint (WxDxH): 800 x 800 x 1.260 mm

- Capacity: 80 L

- Empty weight: approx. 60 kg

- Built-in vibrator for even dosing

- Regular filter loading after cleaning

- Access to rotary valve via inspection opening

- Lid with convenient toggle locks

Options & variations

Optionally, up to three side extraction hoods can be fitted to directly extract rising precoating agent when filling the system, thus effectively protecting your employees. The control can be separate or integrated into the control of the extraction system.

CONTROL

Separate or integrated into extraction system

EXTRACTION HOOD

One to three sided

HARTING PLUG

Convenient interface

CONTROL

Separate or integrated into extraction system

EXTRACTION HOOD

One to three sided

HARTING PLUG

Convenient interface

Fire protection through precoating

Due to the mixing of non-combustible limestone powder and the extracted dust, the concentration of combustible particles is reduced and the risk of fire is minimized.

References precoat units