PRE-SEPARATOR

Pre-separators or pre-filters for extraction systems serve as spark traps or to separate large quantities of dust and chips before the extracted media reach the filter unit. They protect the main filters of the extraction system and ensure a longer filter service life.

More

Security

Low fire risk due to the separation of glowing particles and sparks.

Higher

filter service life

Relief of the main filter at constant extraction power for increased service life.

Reduced

Reduce

Low operating and maintenance costs due to sustained protection of the filter units.

More

Security

Low fire risk due to the separation of glowing particles and sparks.

Higher

filter service life

Relief of the main filter at constant extraction power for increased service life.

Reduced

Reduce

Low operating and maintenance costs due to sustained protection of the filter units.

Functionality

Pre-separators are installed upstream of the extraction systems. Medium and coarse dust particles can be separated up to 99 % in advance, so that only the filtration of fine dust is required. By connecting a pre-separator upstream, the filter service life is significantly increased and follow-up costs are reduced.

Pre-separators from ABSAUGWERK are suitable for every type of unit and can be easily retrofitted. The different designs and sizes guarantee optimum extraction performance with low energy consumption. All pre-separators can also be designed for several extraction systems.

Types of pre-separators

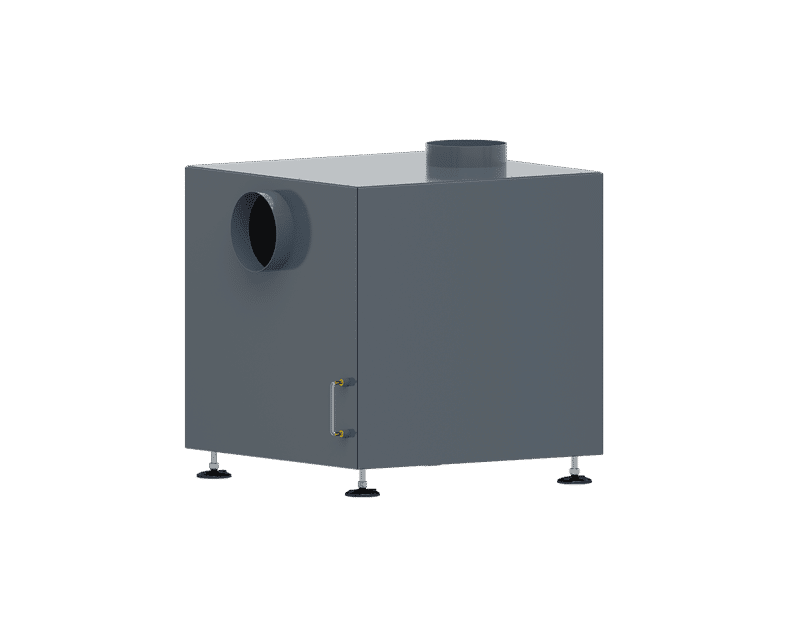

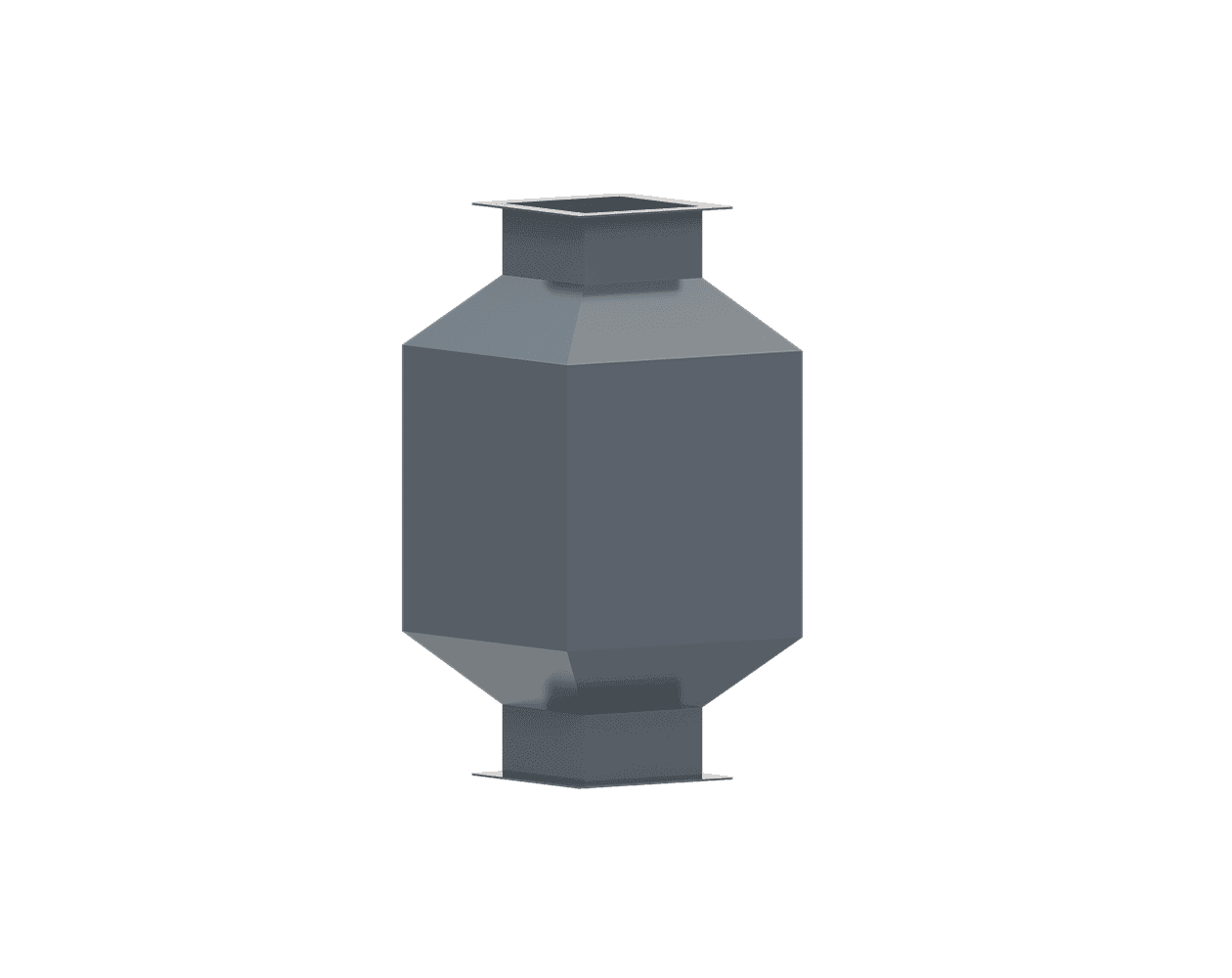

Separate cyclone pre-separator

Separate cyclone pre-separators can be placed independently next to the unit. They have the best separation efficiency.

Side cyclone pre-separator

With its compact and robust design, the side cyclone pre-separator can be installed directly on the unit. This saves space and costs.

Water pre-separator

Water pre-separators bind smoke in a water bath and extinguish sparks or glowing particles with a separation efficiency of almost 100 %.

Spark trap

The spark trap is placed between the capture and the pipe system. Due to the reduced air velocity in the spark pre-separator, the sparks cool down and extinguish.

FAQs

Individual pre-separators

In addition to the standard designs, we also offer special designs for pre-separators such as zigzag pre-separators or non-return valves.

Thereby we try to fulfill every demand.

Let us advise you!

Explosion and fire protection

If a spark gets into the filter unit, serious explosions and violent fires can occur. To guarantee the safety of employees and industrial units, so-called ATEX directives (ATmosphères EXplosibles) apply. Our ATEX-compliant extraction systems guide the air in a flow-optimized manner via pipe systems into the pre-separator and thus prevent the penetration of possible sparks. In addition, a number of other measures provide additional protection.