Air handling units in industry

What is there to consider with air handling units?

Ventilation systems, so-called air handling units (AHU), influence or control the condition of the room air in production halls with regard to temperature, humidity, pollutant load and quality. They provide both air exchange, filtration and tempering of the air. The polluted hall air is continuously extracted, filtered and, if necessary, enriched with fresh air. The use of air handling units thus ensures a high level of safety in terms of health, occupational safety and fire/explosion protection. Viruses and aerosols can also be effectively filtered out of the hall air by using so-called HEPA H14 filters.

Fields of application in industry

Production halls

Warehouses

Freight forwarding

Goods transshipment points

Technical rules

for workplaces

(ASR)

The Technical Rules for Workplaces ASR A 3.6 »Ventilation« stipulate that RTL systems must be state of the art and operated in accordance with their intended use. Maintenance of the equipment must be carried out at regular intervals in accordance with § 4 of the Workplace Ordinance (ArbStättV). Within the framework of a risk assessment according to § 3 ArbStättV, the requirements for an air handling unit must be checked and specified. Furthermore, information must be provided about possible health hazards that may occur in the event of failure or malfunction of the air handling unit.

The employer is responsible for determining the maintenance intervals so that the technical, hygienic and ventilation properties and safe operation of the equipment are ensured during the entire period of operation. The VDI 6022 »Hygiene requirements for air handling systems and units« describes the hygiene requirements, while DIN EN 12599 »Test and measurement procedures for the handover of installed air handling systems« explains the acceptance test.

Get individual advice

We will help you find the best solution for your hall extraction system.

Feel free to contact us.

Air handling units from ABSAUGWERK

FILTER TOWER

HALL EXTRACTION

System components

Ventilation systems

Filter

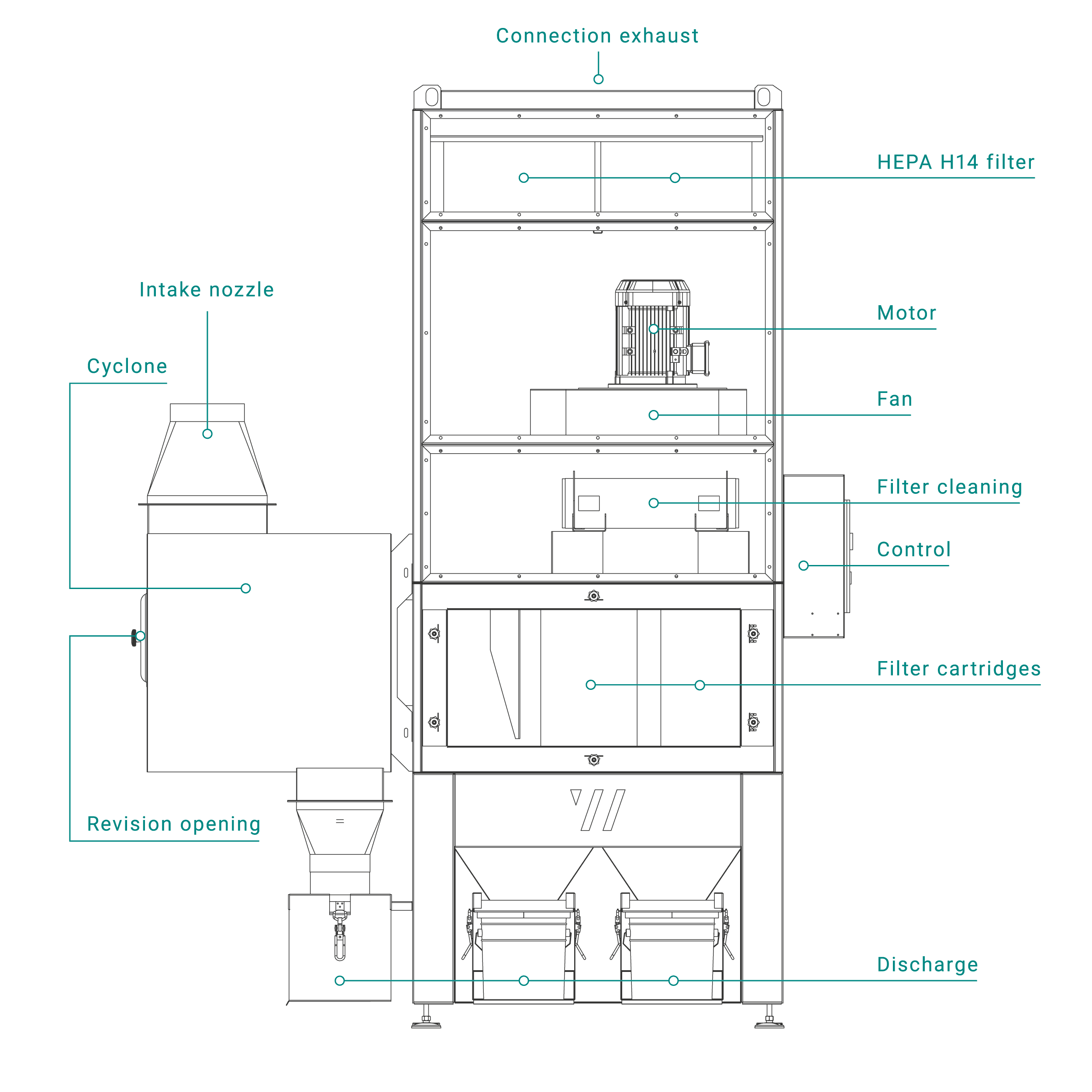

The filters are selected according to the amount and nature of the extracted material such as smoke, dust or oil mist. The filter area is also crucial for effective extraction. Commonly used are bag, cartridge or cassette filters. For carcinogenic fine dusts or viruses, additional HEPA H14 filters are integrated into air handling units.

Cleaning

To avoid premature clogging of the filters, they should be cleaned regularly. This can be done manually or automatically via jet pulse cleaning. Here, compressed air is fed into the filter unit, which blows the so-called dust cake from the filters.

Fans

The fan draws air through the AHU according to a calculated volume flow. The extraction must not only carry enough air, but also the pollutants in the air without deposits through the system and filters. The fan consumes the most electricity and must therefore be economically sized. So-called EC fans consume significantly less electricity and are easy on the environment and your wallet.

Heating and cooling coil

Up to 70% heating costs can be saved via a cross-heat exchanger. In this process, the warm air containing pollutants heats chambers through which the fresh air flows.

Control

Innovative controls such as the SIEMENS LOGO!8 are not only responsible for the proper operation of an air handling unit, but also regulate performance and energy consumption (summer/winter switchover). In addition, communication with system components such as the precoat unit, fire protection device, filter cleaning system, etc. is carried out in this way. and much more

Pre-separator

Pre-separators serve as spark traps and to separate large quantities of material before the extracted media reaches the filter unit. This considerably increases the filter service life.

Precoat-Unit

In order to prolong the life and effectiveness of filters in extraction systems, precoat units are often used, which periodically coat the filters with slaked lime or other precoating agents (so-called filter aids) to the filters. Sticky, oily and moist media can thus not immediately stick to the filter material and filter cleaning is significantly improved.

Capture

The right capture element is crucial for effective extraction of industrial emissions. These include extraction arms, extraction hoods and extraction tables in various sizes and designs, as well as individual acquisition components.

Discharge

The solids, which are bound by the filters, collect in a so-called discharge. These can be buckets, bins, containers or special discharge systems. Depending on the type of material and quantity, different sizes and designs are offered.

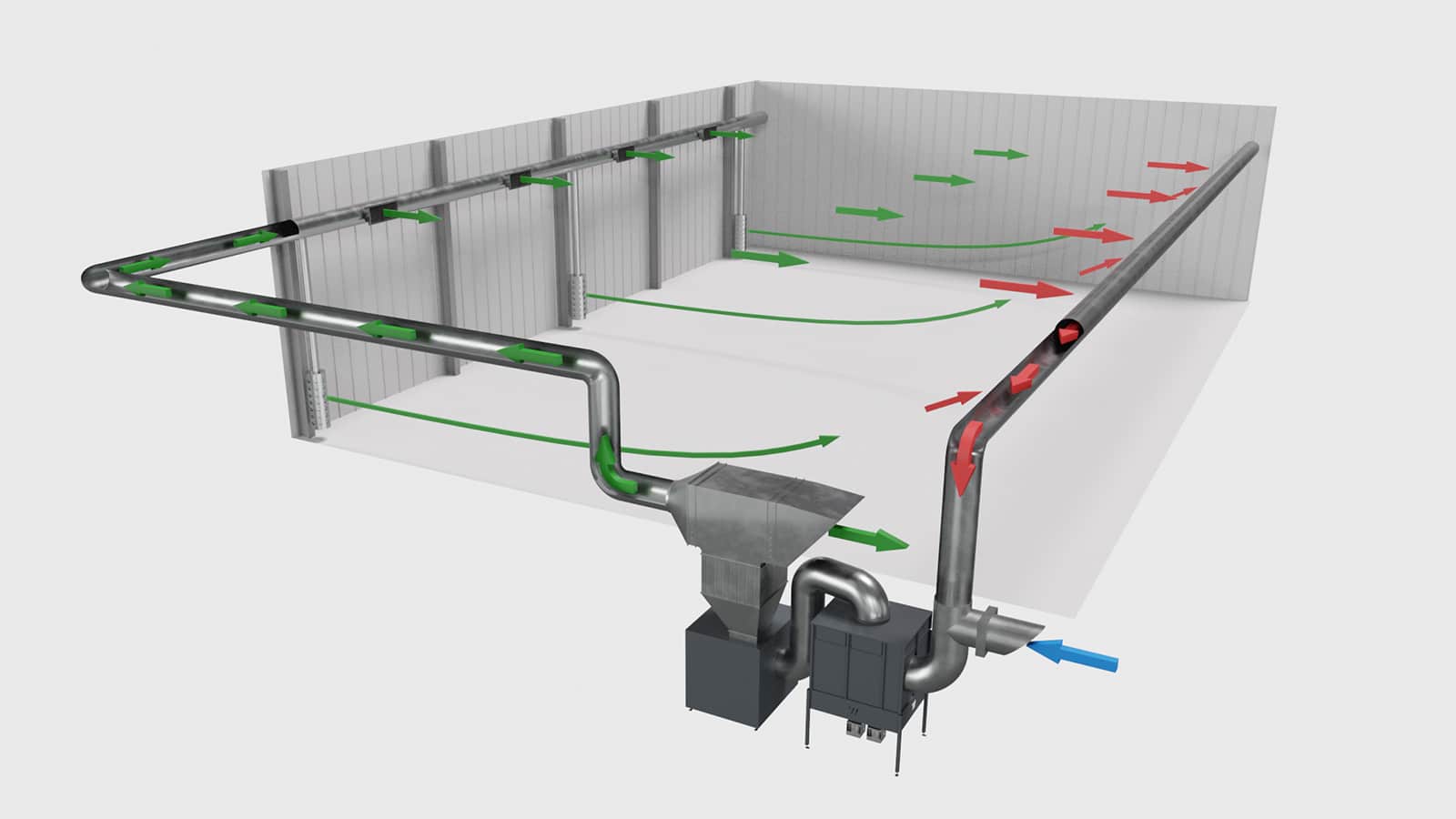

Pipe system

Pipe systems feed the polluted air to the extraction system and the cleaned air back into the hall or outside. Here, too, there are different types of texture and size, e.g. spiral duct or steel pipe.

Sound insulation

For large air volumes, fans with sufficient power must be used. Surrounding employees are protected from excessive noise exposure with silencers in the extraction system and pipe system.

Fire and explosion protection

Should a spark reach the filter unit, precautionary fire protection measures must be taken, e.g. spark sensor system with automatic powder extinguishing system. In certain mixing ratios of oxygen, explosive media and an ignition source, AHUs can self-ignite or even explode. Therefore, certain explosion protection components (ATEX) necessary during planning.

Coating

For outdoor use, the equipment should have a special weatherproof coating and the control cabinet should be moved inside.

For a healthy indoor climate