ABSAUGANLAGEN

FÜR DIE LEBENSMITTELINDUSTRIEHerausforderungen für Absauganlagen in der Lebensmittelindustrie

Bei der Herstellung von Lebensmitteln wie Gummibärchen, Backwaren, Tee oder Kaffeebohnen entstehen Grob- und Feinstäube, die sämtliche Oberflächen bedecken, sich in der Luft verbreiten und so zu Querkontaminationen und Allergien führen können. Gemäß Verordnung (EG) Nr. 852/2004 des Europäischen Parlaments sind bei der Lebensmittelherstellung strenge Hygienevorschriften einzuhalten. Um diesen Anforderungen gerecht zu werden, müssen Absauganlagen für die Lebensmittelindustrie aus Edelstahl hergestellt sein. Wir entwickeln maßgeschneiderte Absauglösungen für Ihren Prozess und bietet eine umfassende Lösung von der Erfassung bis zum Rohrsystem. Für explosive und brennbare Stäube, wie bei Mehl oder Kräutern, bieten wir spezielle ATEX- und Brandschutzausführungen an.

PROZESSE

- Transport von Roh- und Grundstoffen

- Manuelle oder maschinelle Arbeitsprozesse:

Mahlen, Formen, Mischen, Kneten, Einstäuben - Abfüllen, Umfüllen, Mischen

- Reinigen, Verpacken

MEDIEN

- Brand- und explosionsgefährliche Stäube z. B. Mehlstaub oder Gewürze

- Kunstoffgranulat

- Sand und Stäube

- Pulversubstanzen

- Sonstiges Schüttgut und rieselfähige Stoffe

BEREICHE

- Getreide, Mehl, Stärke

- Milchprodukte

- Kaffee, Tee und Tabak

- Zucker, Süßwaren und Cerealien

- Samen, Kräuter und Gewürze

- Suppen

Warum Absaugen?

Eine effektive Absaugung in der Lebensmittelherstellung schützt Mitarbeiter, Maschinen und Produkte vor Verunreinigungen durch Fein- und Grobstaub und gewährleistet die Qualität Ihrer Erzeugnisse.

Hygiene & Explosionsschutz in der Lebensmittelindustrie umfassen:

- Absaugung von Grobstäuben an den Maschinen

- Absaugung und Filtration von Feinstaub und Aerosolen

- Verwendung von Edelstahl-Komponenten gemäß Hygienevorschriften

- Einhaltung der ATEX-Richtlinien für explosive Stäube

- Zertifizierte, hochwertige Filtermedien

- Integration von Vorabscheidern

Die passende Absauganlage speziell für die Ihren Anwendungsfall

NASSABSCHEIDER

ENTSTAUBER

RAUCHFILTER

VORABSCHEIDER

Ihre Vorteile

Unsere flexiblen Absauglösungen passen sich mühelos an die komplexen Produktionsabläufe und den hohen Automatisierungsgrad der Lebensmittelbranche an. Selbst spezielle Anforderungen wie prozessintegrierte Inline-Anlagen, besondere Hygienevorschriften oder Dauerbetrieb können durch die maßgeschneiderten Lösungen erfüllt werden. Mit ABSAUGWERK erhalten Sie nicht nur Flexibilität, sondern auch eine optimale Anpassung an die individuellen Bedürfnisse Ihrer Produktion.

SAUBERKEIT &

HYGIENE

Hygienemängel verursachen teure Rückrufaktionen, Bußgelder und Reputationsschäden. Eine sichere Filtration von brennbaren Stäuben ist entscheidend, um Ihre Mitarbeiter zu schützen und Brände oder Explosionen zu vermeiden.

NIEDRIGE

FOLGEKOSTEN

Langlebige Anlagenkomponenten und individuell konfigurierte Absaugsysteme reduzieren die Betriebs- und Folgekosten auf ein Minimum.

ENERGIE-

EFFIZIENZ

Energetische Komponenten und intelligente Steuerung ermöglichen automatische Leistungsregelung sowie Umluft- oder Abluftbetrieb, während die Wärmerückgewinnung Energie- und Heizkosten einspart.

WELTWEITER

SERVICE

Via Fernwartung unterstützen wir Sie weltweit von der Beratung bis zur Montage und bieten umfassenden After-Sales-Service.

Individuelle Absaugsysteme für die Lebensmittelindustrie

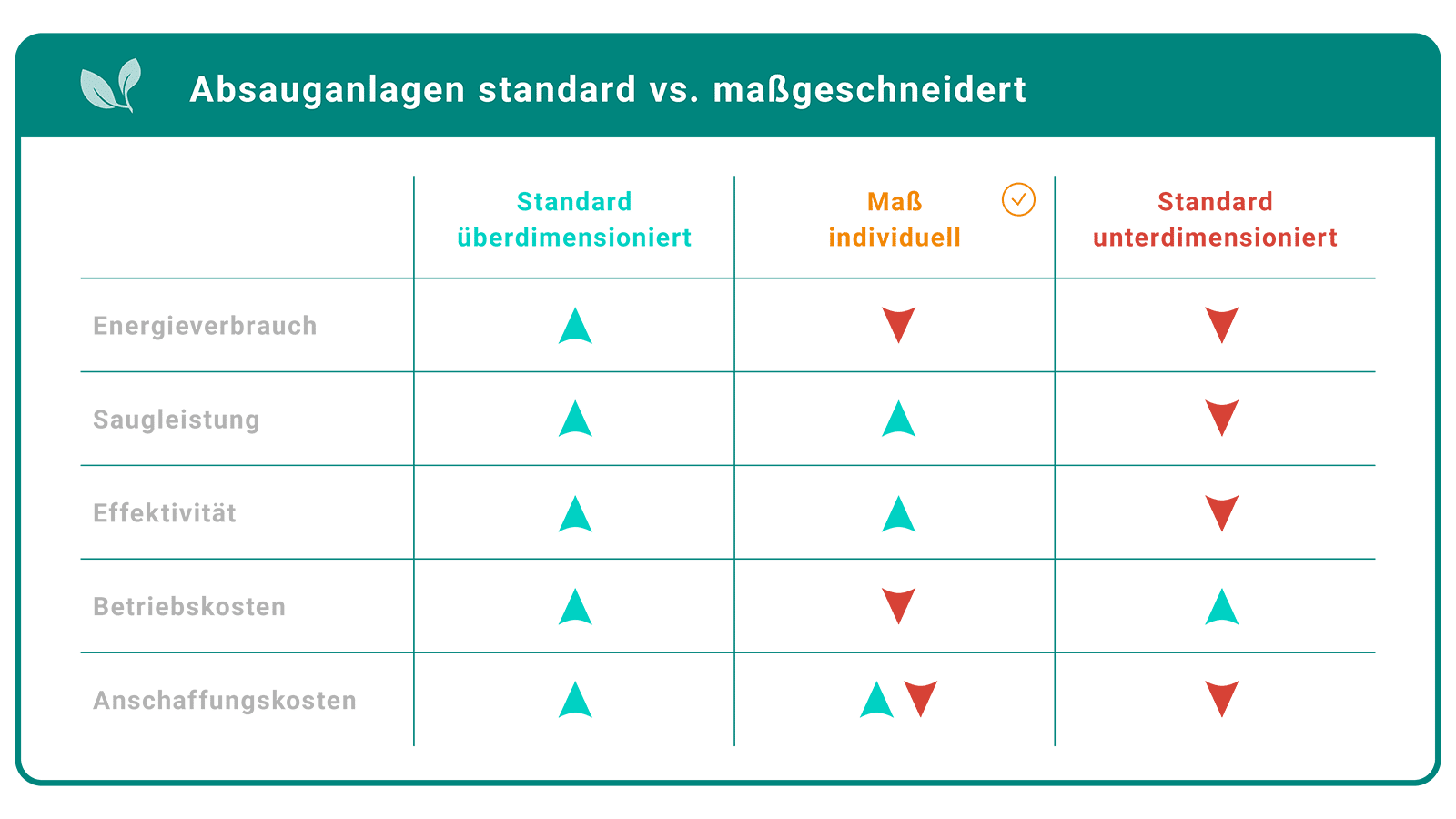

Wir konfigurieren unsere Anlagen entsprechend Ihrem Anwendungsfall und gewährleisten maximale Saugleistung bei minimalem Energieverbrauch. Nutzen Sie unsere Erfahrung in der Lebensmittelbranche, um gemeinsam Ihren Prozess zu optimieren.

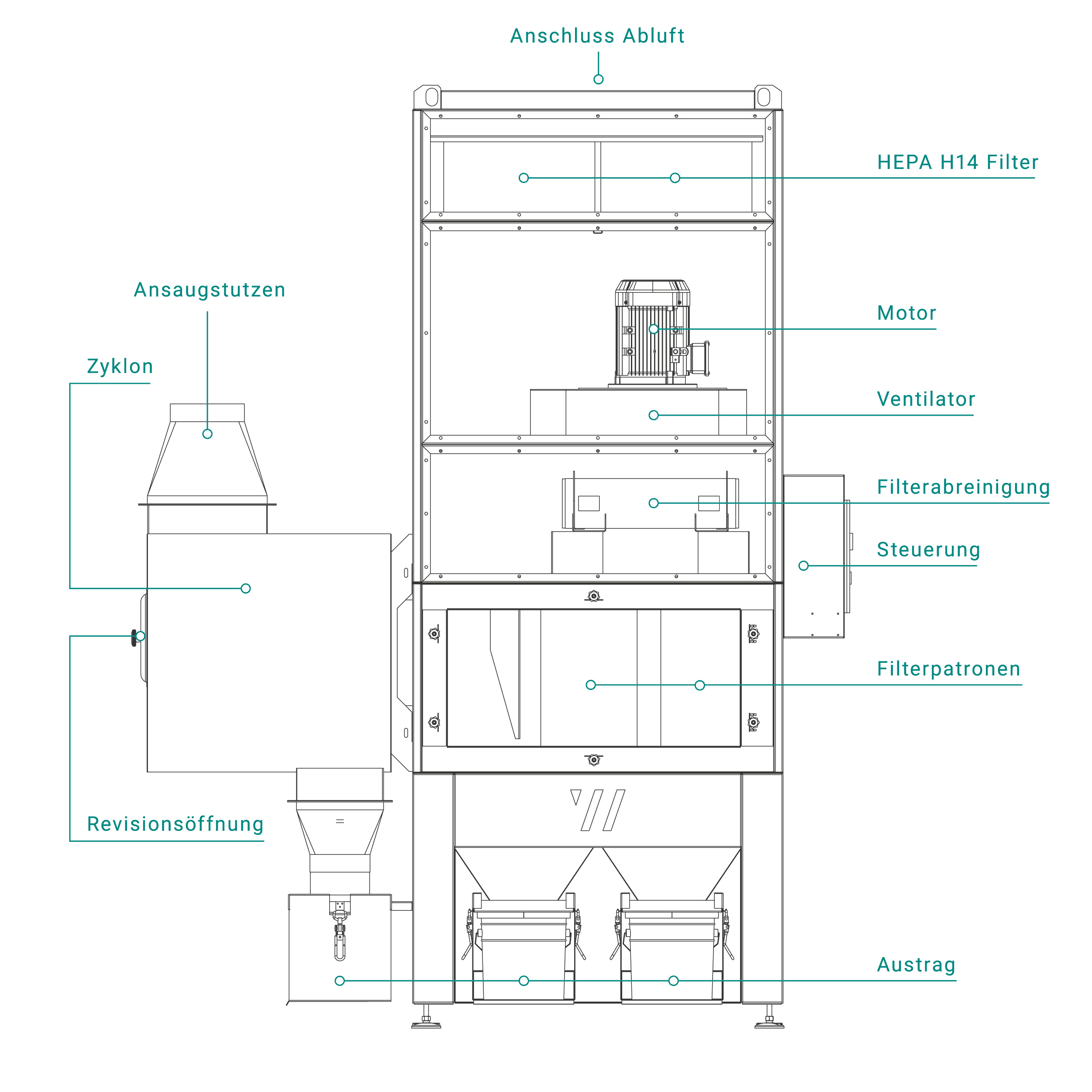

Zyklonvorabscheider

Vorabscheider kommen bei großen Materialmengen zum Einsatz, um die Hauptfilter zu schonen. Bei explosiven Medien dienen sie als Funkenfalle, um Brände und Explosionen zu vermeiden.

Erfassung

Für eine effektive Absaugung von industriellen Emissionen ist das richtige Erfassungselement, wie z. B. Absaugarm oder Absaughaube, entscheidend.

Austrag

Erfasste Medien können direkt über ein Rohrsystem abgesaugt oder alternativ über ein Austragsystem wie Eimer, Schublade oder (Schlamm-)Behälter entsorgt werden.

Unsere Anlagen sind komplett in Edelstahl-Ausführung verfügbar.

Explosionsschutz für Absauganlagen in der Lebensmittelindustrie

Bei industriellen Prozessen wie Schleifen oder Entgraten werden nicht nur sichtbare, sondern auch unsichtbare Feinstäube freigesetzt, die gefährliche Brände und Explosionen auslösen können. Zu den explosiven Stäuben gehören organische Stoffe wie Mehl, Kaffee oder Cellulose sowie Aluminium oder Magnesium. Um Explosionen zu vermeiden, müssen elektrische Komponenten und weitere Bauteile ATEX-konform verbaut werden.

Haben Sie eine Frage?

Wir erfüllen nicht nur die gesetzlichen Anforderungen für Absauganlagen in der Lebensmittelindustrie, sondern auch Ihre individuellen Bedürfnisse. Kontaktieren Sie uns für einen unverbindlichen Beratungstermin unter +49 731 141 108-0 oder nutzen Sie das Kontaktformular. Wir melden uns schnellstmöglich bei Ihnen zurück.