WITRON - STEEL CONSTRUCTION

Hall extraction & extraction arms for welding fumesWITRON - STEEL CONSTRUCTION

Hall extraction & extraction arms for welding fumesYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers. More Information

WITRON Stahlfertiger GmbH & Co KG produces over 6,000 tons of steel every year. As a close partner of the internationally active logistics system provider WITRON, they realize central components for their highly automated logistics solutions.

As part of the modernization of infrastructure and production, occupational health and safety measures were also specifically expanded, supported by our solutions for clean and safe production environments.

Welding workstations with direct extraction via extraction arms were set up for three halls of the steel construction company and supplemented by an automatic hall extraction system. In addition, two mobile extraction hoods on a welding robot were technically optimized, as the smoke was previously insufficiently extracted and spread uncontrollably in the hall. Due to the location in a mixed-use area, a maximum noise level of 65 dB(A) also had to be complied with. Challenges that we solved reliably.

INDUSTRY

Steel production

PROCESSES

Welding (MAG)

Robot welding

MEDIA

Welding fumes

Requirement:

- 2-fold extraction of welding fumes directly via extraction arms and centrally via a hall extraction system

- Technical optimization of two mobile extraction hoods

- Outdoor installation of the systems

- Sound level < 65 dB(A)

- Fresh air supply

- Energy efficiency with heat recovery

- Remote maintenance

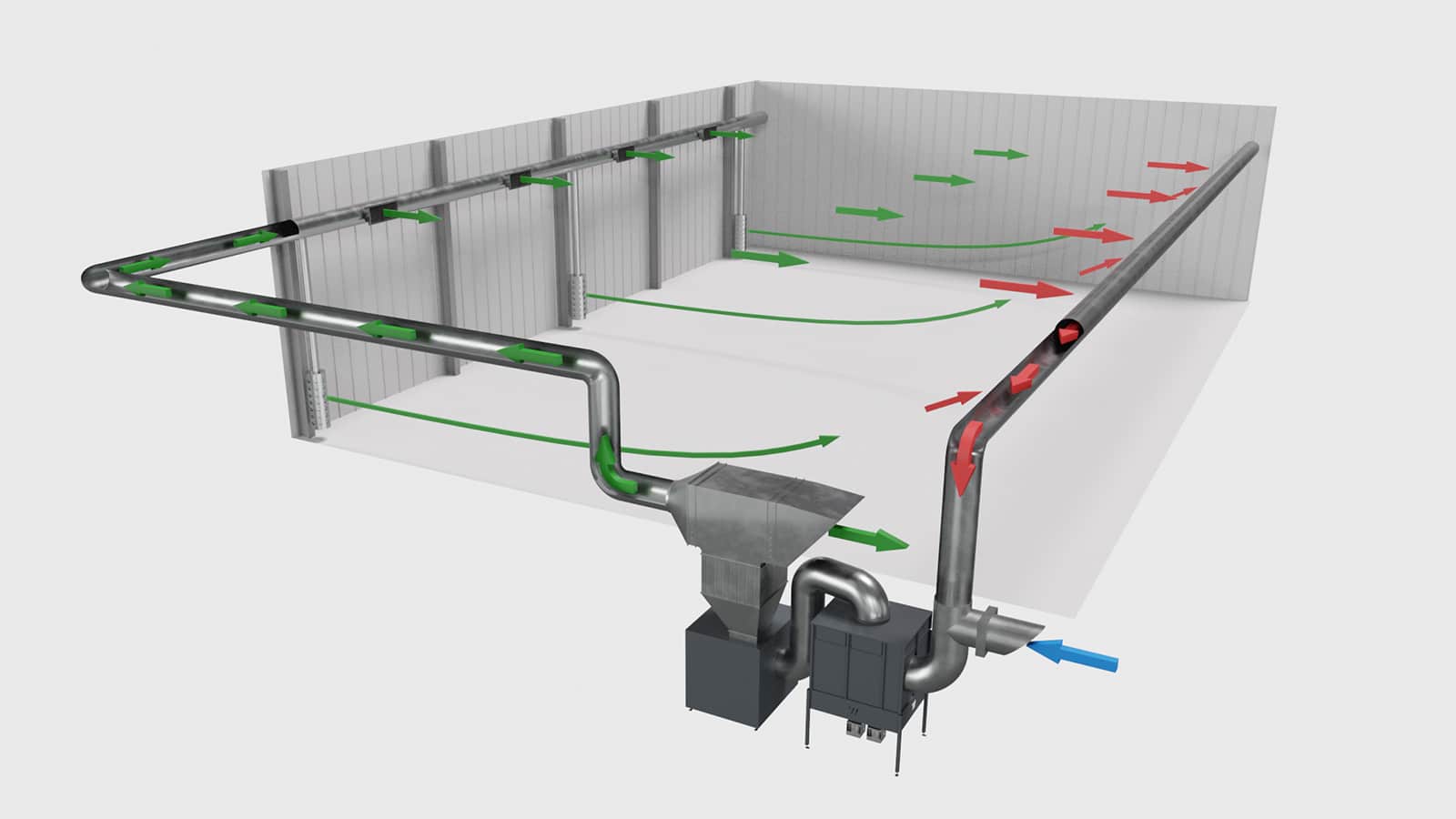

Orange = The contaminated extract air is extracted and filtered.

Green = The clean supply air enriched with fresh air is fed back into the hall.

Our extraction solution:

Extraction arms + hall extraction system

To ensure an efficient workflow, the workstations are equipped with extraction arms and a piping system for hall extraction on the ceiling. Employees can conveniently control the extraction in their area themselves using a toggle switch, allowing them to use either the extraction arms or the hall extraction system.

Extensive

sound insulation

In order to keep the sound level constantly below 65 dB(A) even at maximum power, various sound insulation elements were installed in the pipe system and systems.

Energy-saving ventilation principle

The intelligent control system automatically regulates the fresh air supply, recirculation mode and the system output. This keeps the air quality constant all year round, preserving heat in winter and exchanging it for cooler fresh air in summer.

Result:

✓ 2-fold extraction solution

In the designated work areas, employees can choose between hall extraction or direct extraction. The Push-Pull-Plus principle ensures complete filtration of the hall air without any draught effect.

✓ Future-proof planning

The extraction systems have a flexible design and can provide a higher motor output if required, so that additional workstations can be easily integrated into the extraction system.

✓ Safe operation

The extraction systems meet the legal requirements for occupational safety, dust limits and noise protection and have been approved by TÜV Süd. Dirt and noise remain outside the hall.

Too good to be true!

»The solution was so practical and technically simple that...

Gerhard Braun

WITRON Stahlfertiger GmbH & Co. KG

We support our customers from A to Z: personal advice, technical design, planning of the pipe system, production, installation, piping, commissioning, maintenance and after-sales.

TECHNICAL DATA

- Systems: 2 R 7000 series fume filters

- Performance: 37 kW

- Max. Air volume: 30,500 m³/h

- Air flow: Extract air + fresh air

- Installation: Outdoor area

- Filter: Cartridge filter

- Control system: Siemens LOGO! 8 8 with frequency inverter + SO/WI changeover

- Captures: Push-Pull-Plus pipe system + 12 extraction arms

- Discharge: Dust collection bucket 15 L

- Pipe system: 406 m spiral duct

- Fully automatic jet pulse cleaning

- Fire protection with powder extinguishing system

- Mechanical non-return flap

- Sound insulation

TECHNICAL DATA

- Systems: 2 R 4000 series fume filters,

- Performance: 18.5 kW

- Max. Air volume: 23,000 m³/h

- Air flow: Extract air + fresh air

- Installation: Outdoor area

- Filter: Cartridge filter

- Control system: Siemens LOGO! 8 8 with frequency inverter + SO/WI changeover

- Captures: Push-Pull-Plus pipe system + 6 extraction arms;

also 2 extraction hoods for welding robots - Discharge: Dust collection bucket 15 L

- Pipe system: 363 m spiral duct

- Fully automatic jet pulse cleaning

- Sound insulation

ADVANTAGES AT A GLANCE

- Double protection through alternating direct extraction and hall extraction

- Combined air flow: energy-saving recirculation and exhaust air operation with fresh air supply

- Intelligent control for energy-saving operation

- Flexible system: open for the integration of additional extraction elements and production expansions

- 4 instead of 18: extraction capacity bundled in just four units instead of one welding fume filter per workstation

Our product recommendation for steel fabricators

FUME FILTER SERIES

HALL EXTRACTION

ATEX DEDUSTER

ABSAUGWERK offers first-class extraction solutions for the manufacturing industry that protect people, machines and the environment. We are proud to make workplaces safer and cleaner with our systems. In this way, we actively contribute to the protection of employees, extend the service life of machinery and reduce the environmental impact.