Wet separator

B SERIESWet separator

B SERIESWhat is a wet separator?

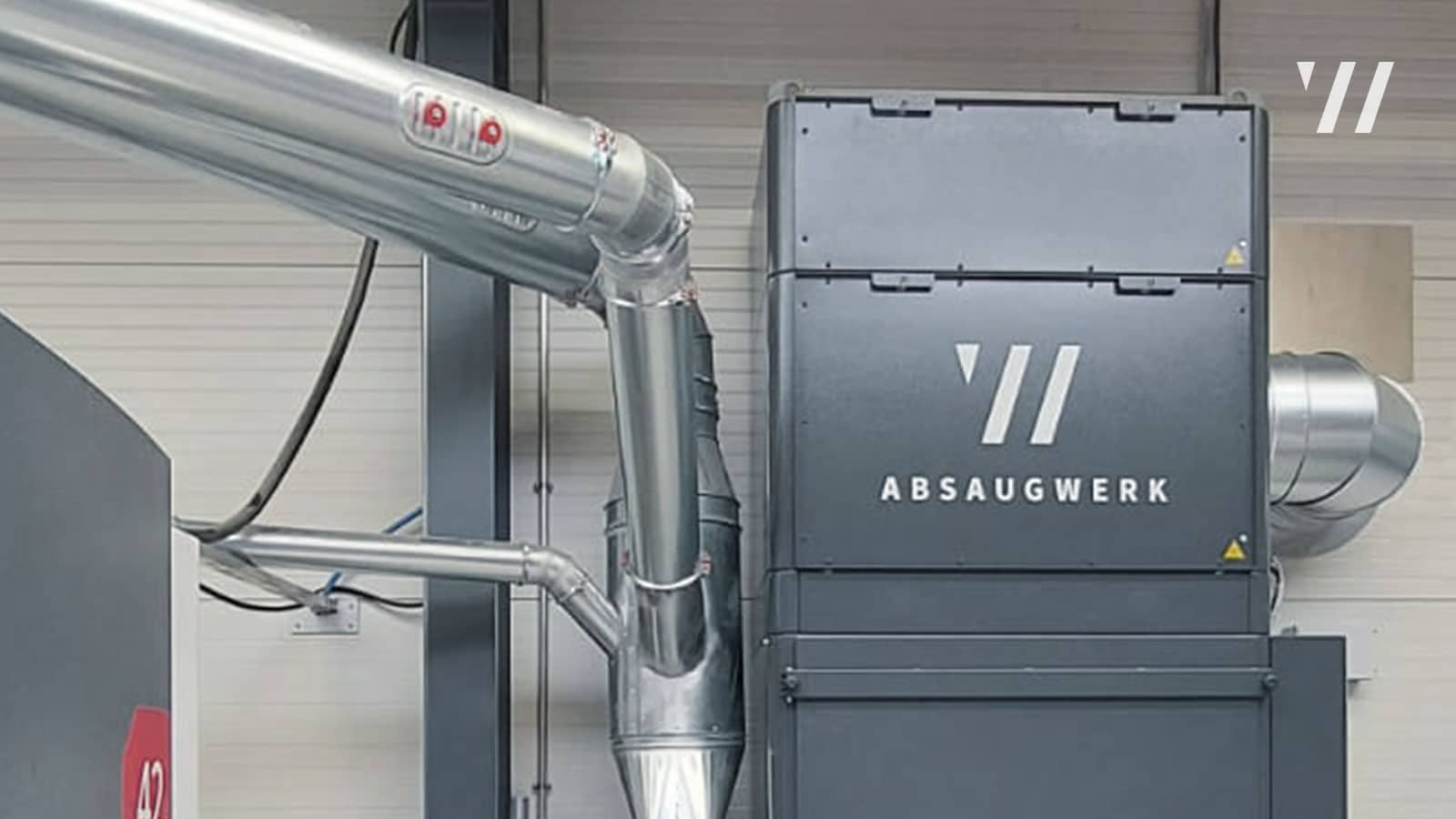

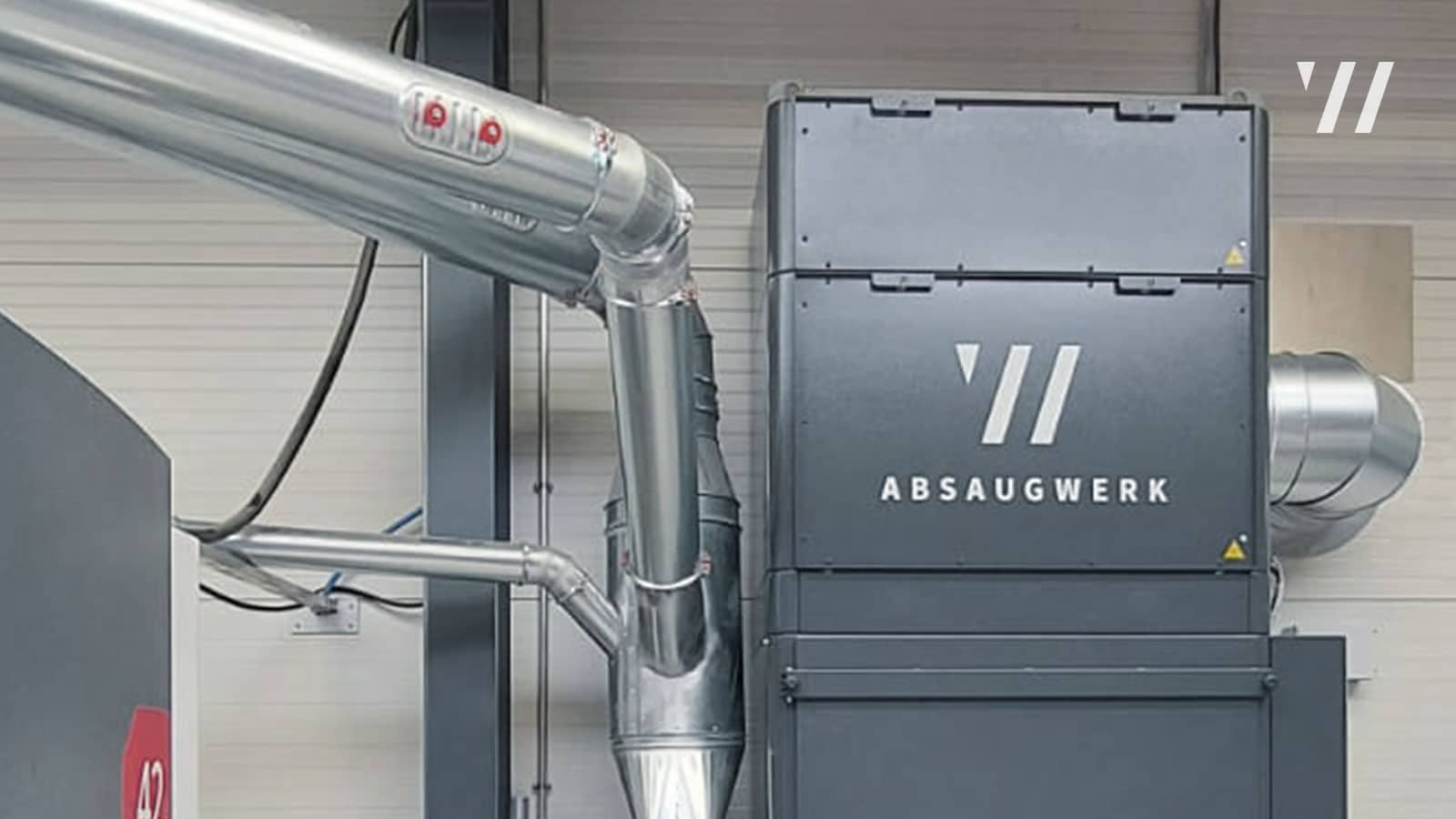

In industrial extraction technology, a wet separator is a filter system that uses water as a filter medium to clean the hall air of dust and chips. The units are particularly suitable for processes with flying sparks and for filtering combustible/explosive dusts (ATEX). There are various techniques for capturing these emissions, each with its own advantages and disadvantages. ABSAUGWERK’s separation technology is patented and particularly energy-saving, despite higher suction power than conventional wet scrubbers, gas scrubbers or vortex scrubbers.

Wet separator for flammable

and explosive dusts

-

Very high extraction power

-

Low water and power consumption

-

Patented flow technology

-

Individual configuration and special solutions

-

Recirculation mode also for carcinogenic substances

Application areas

Metalworking

Chemical industry

Pharmaceuticals

Food luxury food industry

Automotive industry

PROCESSES

Grinding, polishing, cutting, sawing etc.

MEDIA

Dust shavings

Sticky, moist, flammable, explosive

Wet separators are extraction units that bind dust and chips in a stream of water to save energy and effectively clean the extracted air via several filter stages. Coarser particles settle in the water and are collected directly in a discharge container. Any fine dust still present is separated via several filter stages. For carcinogenic substances such as stainless steel dusts, the use of additional HEPA H14 filters is recommended.

The cleaned air can then be fed back into the production room or outside. Special ATEX components are required for explosive media to ensure safe operation in hazardous areas.

As a manufacturer of wet separators, we also develop special solutions for special applications and configure our extraction units specifically for our customers’ processes.

%

MORE

EXTRACTION POWER

%

LESS ENERGY COSTS

PER YEAR

%

MORE

FILTER SURFACE

%

LESS WATER CONSUMPTION

PER YEAR

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationService videos wet separators

From the safe installation of an extraction unit and commissioning to filter changes and cleaning. We regularly publish new service and product videos on our YouTube channel to make the use of our extraction units even more customer-friendly.

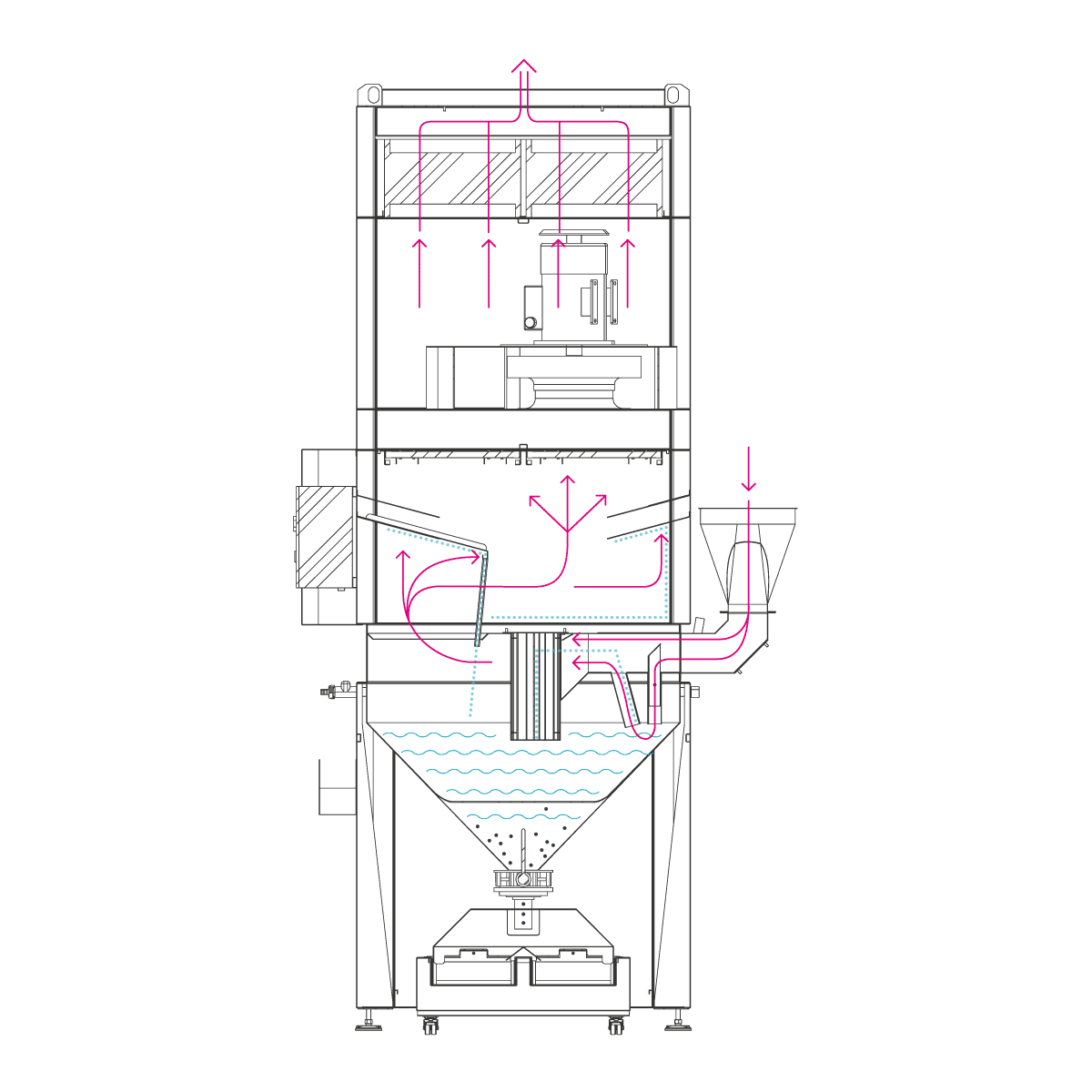

How a wet separator works

The operating principle of our wet separators is based on a patented flow technology that enables a 50 % higher suction capacity with low energy and water consumption.

The revolutionary multi-chamber system separates dusts with low resistance in water, providing highly efficient protection against fire or deflagration. The residual moisture in the air is separated via several filter stages and a stainless steel droplet separator.

The interior of the wet separator is conveniently accessible for cleaning work via several inspection openings. This saves valuable time during cleaning and maintenance. The innovative technology is also reflected in the design and is unique in the industry.

The cleaned air can then be fed back into the hall (recirculation mode) or outdoors in exhaust mode.

System components wet separator

FILTER

- Cleanable stainless-steel metal mesh

- Multiple filter stages for max. separation efficiency

- Robust quality filters

- Long filter service lifetime

CAPTURE

- Extraction arm

- Extraction table

- Extraction hood

- Machine connection

- Individual recording system

TECHNICAL DATA

- Motor power: 1.1–15 kW

- Fan capacity: 2.350–18.000 m³/h

- Operating time: 24 hours per day

DISCHARGE

- Container (different sizes)

- Pinch valve

- Ball valve

- Sludge container (different sizes)

- Gate valve manual/el./pneumatic

- Continuous discharge systems

- Individual discharge system

Options & variations

HEPA H14 FILTER

Against carcinogenic substances

ACTIVATED CARBON FILTER

Against gases and odors

EXPLOSION PROTECTION

ATEX execution

Fire protection

Automatic extinguishing system

noise protection

Effective and safe

INTELLIGENT CONTROL

Versatile operating options

unit color & branding

Individual as desired

Wet separator cleaning & care

Depending on the degree of soiling, we recommend cleaning the wet separators once a week. Regular cleaning of the pipe transition, droplet separator and discharge container prevents the build-up of deposits and ensures optimum operation with consistent suction power. A clean extraction unit also minimizes the risk of explosion and the separation performance of the filters is not impaired. All you need to clean our wet separators are gloves and a clean cloth.

Cleaning droplet separator

The droplet separator consists of a specially developed stainless steel mesh. The material is rustproof and can be washed out with a conventional high-pressure cleaner. To keep your employees clean and dry, we have also developed a special cleaning station, the Cleanbox. The droplet separators are simply clamped in place and the dirty water collects in a trough.

ATEX wet separator

In the correct mixing ratio with oxygen and an effective ignition source, flammable and explosive particles in the form of gas, vapor, mist or dust can form an explosive atmosphere. If a fire or explosion develops, people can be injured, buildings and unit components destroyed and other flammable substances ignited.

So-called ATEX directives (ATmosphères EXplosibles) therefore apply to extraction units such as dedusters, wet separators or welding fume filters for potentially explosive areas in which flammable substances such as aluminum can be processed industrially.

As a manufacturer of ATEX wet separators, safe operation and the protection of your employees is our top priority. This is why the ATEX wet separators from ABSAUGWERK are designed according to the primary explosion protection principle and have special ATEX components installed.

ATEX measures

- Air speed in the pipe min. > > 20 m/s

- Negative pressure and volume flow monitoring

- Motor according to ATEX Zone 22

- Construction free of ignition sources and conductive

- No ex-zones during operation

- All electrical components installed ATEX-compliant

- Electrical cabinet outside the system

Environmental protection & sustainability

When developing our wet separator series, our aim was to achieve the highest suction performance in the industry with minimal energy and water consumption. The principle of our customized extraction units is based on individual configuration. We develop individual solutions specifically for your application using various captures, performance sizes and discharge systems. This enables us to supply economical, energy-saving, state-of-the-art extraction units.

For the green industry of today and tomorrow.

High-quality workmanship

for a long service life

Lower energy costs

per year

Certified

HEPA H14 filter

Summer/winter changeover

through intelligent control

Reduced heating costs

due to cross heat exchanger

Water savings

up to 7,200 L/year

No expensive

EX protection components

Automatic regulation

of the air flow rate

References wet separators

Our customized extraction systems are used in a wide range of industries. Wet separators are particularly suitable for separating sticky, moist or flammable particles that are produced during work such as grinding or polishing. Unlike dry separators, wet separators use water as the main filter medium. The purified air can be fed back into the hall as exhaust air outside or in recirculation mode. The discharge can be collected in a container, via a pinch valve or other discharge systems according to customer requirements. All wet separators are also available as ATEX compliant for explosive dust particles.

Quadrus Metal Engineering

“ABSAUGWERK is characterized by very high extraction performance and good service. That’s why we opted for this extraction system.”

FAQs

We are happy to help!

We provide you with comprehensive technical expertise for the planning and consultation of your wet separator. We work together to develop customized solutions and will be happy to provide you with an individual offer.