Pieé

Extraction for metal dustPieé

Extraction for metal dust

Pieé CNC-Blechbearbeitung GmbH specializes in precision sheet metal processing and offers tailor-made solutions for various industries. Using state-of-the-art CNC technology, the company manufactures high-quality products such as sheet metal housings, control cabinets and individual components.

Parts made of stainless steel, aluminum and mild steel are ground and welded in a production room. An extraction system was required for the metal dust mixture of stainless steel, aluminum and mild steel. The work tables also needed to be able to be positioned flexibly in the room.

INDUSTRY

Sheet metal processing

Powder coating

PROCESSES

Welding

Grinding

MEDIA

Dust mixture of:

mild steel, stainless steel &

aluminum

Welding fumes

Requirement:

- Extraction of metal dust and welding fumes

- Spatial captures for flexible workstations

- Filtration of mixed metal dusts: aluminum, stainless steel, mild steel

- Low ceiling height

- 4 workstations with 100% simultaneity

Our extraction solution:

Filtration of the entire room air

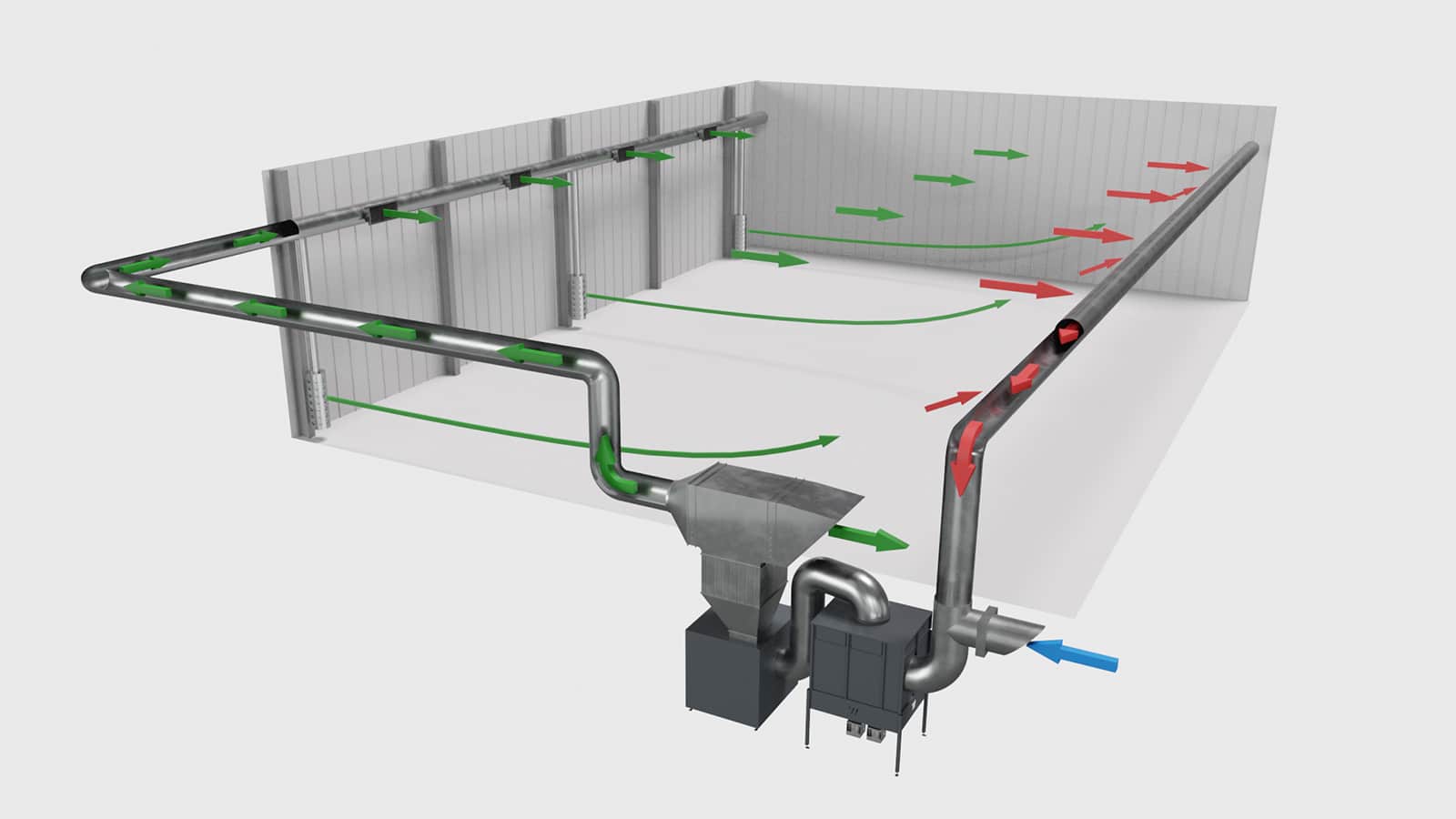

A Push-Pull-Plus hall extraction system was installed for maximum flexibility in the production room. The room air is extracted via grilles in the pipe system, filtered in an extraction unit and returned draught-free via displacement outlets. This creates a constant air cycle.

Safe grinding & welding

Aluminum dust is flammable and explosive, which is why special technical protective measures are required in accordance with ATEX directives. These include spark detection, extinguishing equipment, electrically conductive components and much more.

Stainless steel + HEPA = cancer-free

Stainless steel dust is particularly fine and highly carcinogenic. We have therefore installed an additional HEPA H14 filter, which is also used in laboratories and the pharmaceutical industry.

Result:

✓ Compliant with the law

Combustible and carcinogenic particles are reliably filtered so that all legal requirements are met to the highest technical standard.

✓ Inexpensive to operate

The centrally controlled air circuit in recirculation mode saves considerable energy costs in winter and can be enriched with fresh air in summer.

✓ One for all

Air filtration in a central extraction unit saves energy, maintenance costs and replacement filters. In addition, the welding fume filter could be installed outside the work area according to customer requirements.

We support our customers from A to Z: personal advice, technical design, planning of the pipe system, production, installation, piping, commissioning, maintenance and after-sales.

TECHNICAL DATA

- System: Deduster series P 3000

- Performance: 11 kW

- Max. air volume: 15,000 m³/h

- Air flow: Extract air + fresh air

- Installation: Indoor area

- Filter: Cartridge filter, HEPA H14 filter

- Control system: Siemens LOGO! 8 with frequency inverter and much more

- Captures: Push-Pull-Plus piping system + 6 extraction columns

- Discharge: 2 dust collection bins 30 L

- Pipe system: 21 m longitudinal seam pipe, 32 m spiral seam pipe

- Fully automatic jet pulse cleaning

- Cyclone pre-separator

- Precoat unit

- ATEX execution

- Fire protection with powder extinguishing system

ADVANTAGES AT A GLANCE

- Individual, economical extraction solutions with pipe system

- ATEX dry extraction in indoor areas

- High extraction power

- Low energy consumption

- Low operating costs

- Planning and installation directly from the manufacturer

Extraction techniques for metal dust

DEDUSTER SERIES

HALL EXTRACTION

ATEX SYSTEMS

ABSAUGWERK offers first-class extraction solutions for the manufacturing industry that protect people, machines and the environment. We are proud to make workplaces safer and cleaner with our systems. In this way, we actively contribute to the protection of employees, extend the service life of machinery and reduce the environmental impact.