INDUSTRY SECTORS

Hazardous emissions from industrial processes occur in almost all industries and must be reliably extracted in order to protect workers and machines and comply with occupational health and safety guidelines. We adapt our flexible extraction systems specifically to the respective industry and your application in order to find the right solution for every area.

Metal

The processing and extraction of metal or iron produces chips, dust or fumes. Due to applicable occupational health and safety guidelines, legal regulations and to optimize production processes, these media must be safely collected and extracted. When processing explosive, flammable or carcinogenic substances, we offer special designs to efficiently protect employees and machinery.

Mechanical Engineering

Various production processes such as welding, grinding, sawing, soldering, and drilling are used in mechanical engineering.

These processes generate smoke, dust, chips, and gases that must be safely extracted to protect people and machines. With our extraction systems, we not only improve the indoor air in production halls, but also ensure the quality of your end products and protect your machinery. Clean workplaces significantly minimize the risk of accidents and increase the satisfaction of your employees.

Food

In the luxury food and beverage industry, special hygiene standards and other legal requirements must be met in order to comply with inspections and certification requirements. Reliable extraction is required to protect machines, workstations and end products from coarse and fine dust and other contaminants. Our flexible extraction systems can also be adapted to complex production processes with a high degree of automation to ensure the high quality of your end product. We offer special ATEX and fire protection versions for explosive and flammable media, such as flour or herbs.

Building materials

Despite the enormous technical development in mining and in the building materials industry, coarse and fine dusts are produced during the processing, extraction and transportation of stone or earth. Fine dusts (so-called A-dusts) can penetrate into the lungs and are extremely harmful to health or even carcinogenic. In order to protect machines, workplaces and, above all, employees, the resulting media must be reliably collected and extracted. For larger quantities of dust, direct extraction at the machine and additional room or hall ventilation are recommended. room or hall ventilation.

Medical technology

The processing of chemical base materials by weighing, grinding, mixing or decanting releases dusts that settle in the production room and on machines. In addition, harmful, carcinogenic and even explosive substances can escape, which must be safely extracted to protect employees. We also adapt our flexible extraction systems to complex production processes with a high degree of automation in order to guarantee the quality of your end products. We offer special ATEX and fire protection versions for explosive and flammable media such as magnesium.

Environment and recycling

During the processing of recycling material, dust, chips and fibers of a wide variety of materials are produced by crushing, shredding, transferring and separating. Depending on its composition, the material mix can be hazardous to health, flammable or even explosive. Our flexible extraction systems can be connected directly to machines or machining centers and can also be integrated into complex production processes. The cleaned air can then either be returned to the room or discharged outside. Unpleasant odors are neutralized by special filter elements.

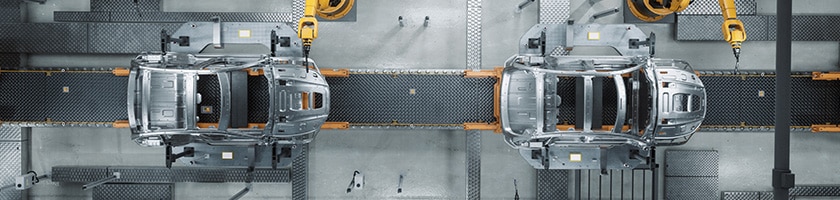

Automotive

In this industry, effective just-in-time production and the quality of the workpieces are crucial to success. Production losses due to dirty machinery, defective end products or even inadequate workplace conditions are usually associated with high costs. With our extraction systems for fume, dust or chips, we not only improve the ambient air in production halls, but also ensure the quality of your end products and protect the machinery. Clean workplaces significantly reduce the risk of accidents and increase the satisfaction of your employees.

On the safe side

Certain regulations apply when processing flammable or explosive media. Find out more here:

Still unsure? Our sales team will be happy to answer your questions and provide you with more information.