Dry separator or wet separator

Dry dust extractor or wet separator?

Whether a wet separator or dry deduster is the ideal filter system for your application depends on the nature of the substances released, the quantity and the physical properties of the dusts or fumes. Is the dust dry, moist, sticky, flammable, explosive or carcinogenic? Are sparks generated during machining? How to capture and how many workstations / machines to exhaust? These factors determine whether wet or dry extraction is the most effective and economical system for your process and whether legal regulations can be complied with.

Areas of application for extraction units

In industry, hazardous substances are produced during grinding, polishing or welding, which must be extracted from the air and filtered in order to protect the workforce and comply with legal regulations. Filter systems such as dedusters, wet separators or welding fume filters filter these emissions from the hall air of manufacturing companies by using different filter media (e.g. cartridge filters, water, HEPA filters). The extraction technology and filter surface depend on the amount of dust, air volume and the chemical properties of the separated particles.

Functionality dry separator

Dry separators are used for the extraction and filtering of dry or sticky dusts as well as chips, granules, fibers, flakes or fluff. The particles are separated via several filter stages; a certified HEPA H14 filter is also installed for carcinogenic and fine dusts. In processes with combustible dusts or flying sparks, a wireless sensor with automatic extinguishing agent device is used and further fire protection measures are taken.

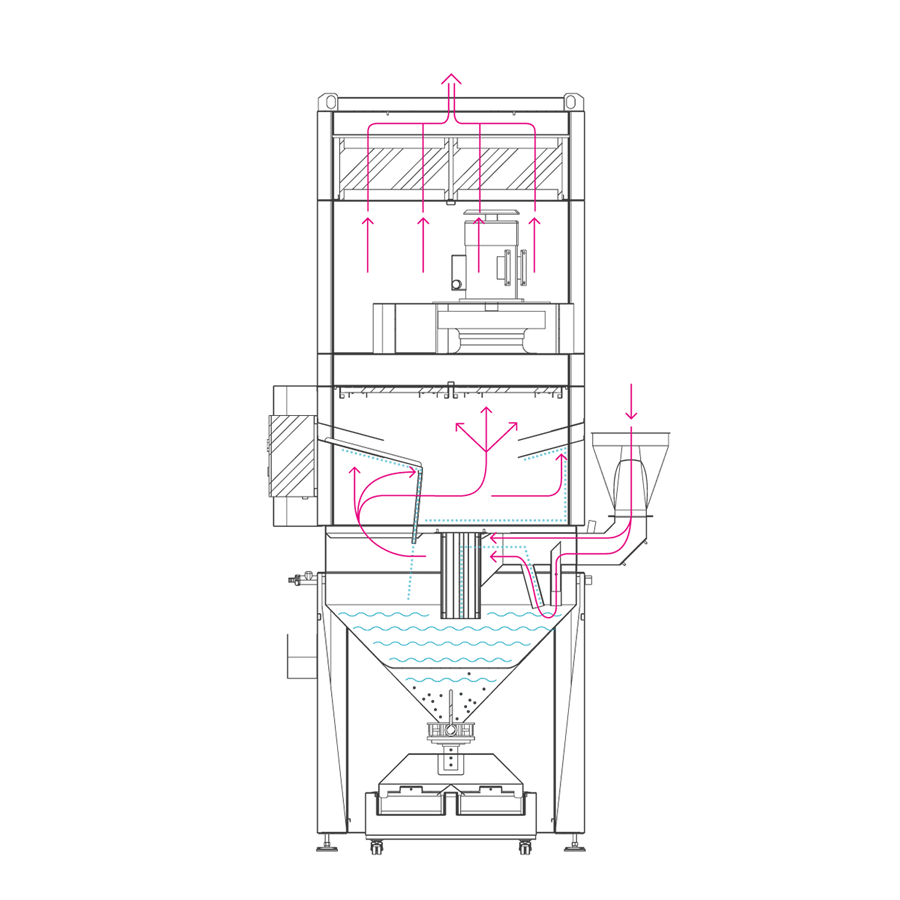

How a wet separator works

The polluted air is extracted through a revolutionary multi-chamber system and dusts are separated in the water. Sparks and combustible dusts are extinguished by high air velocities and the use of water. The discharge is a solid sludge that must be disposed of in accordance with local regulations.

Dry separator suitable for dusts, granules, fibers, …

Application areas dry extraction

Dry dust extractors are all-purpose weapons in extraction technology and are suitable for numerous processes such as sawing, separating, cutting, deburring and many more. Handling and disposing of the discharge is convenient and cost-effective, which is why dedusters are also ideal for processes with a high air flow rate, such as mixing or filling. If the dusts are combustible or sparks are released, we integrate a radio sensor with an extinguishing agent device and other fire protection safety measures.

Advantages

- Very low operating costs

- Cheap & easy disposal of the discharge

- Numerous discharge variants

- Various pre-separators

- Wide range of configuration options

- Cleanable filters & minimal filter wear

- Low costs for wear parts

- Very high separation efficiency of approx. 99.9%(depending on particle size)

Cons

- Cost-intensive extinguishing equipment for combustible dusts required

- Acquisition costs initially more expensive than ATEX wet separators. 💡Compare operating costs!

Wet separator suitable for explosive dusts and chips

Application areas wet extraction

Wet separators are filter systems that are optimally suited for separating explosive dusts due to their technical properties. Sparks are extinguished to a large extent by the high air velocity before the air flow reaches the water basin.

Advantages

- Minimal fire risk

- Low filter wear

- Ideal for sticky, sparking and wet materials

- ATEX version cheaper

Cons

- Higher cleaning and maintenance effort

- Higher disposal costs for the discharge

- Higher operating costs

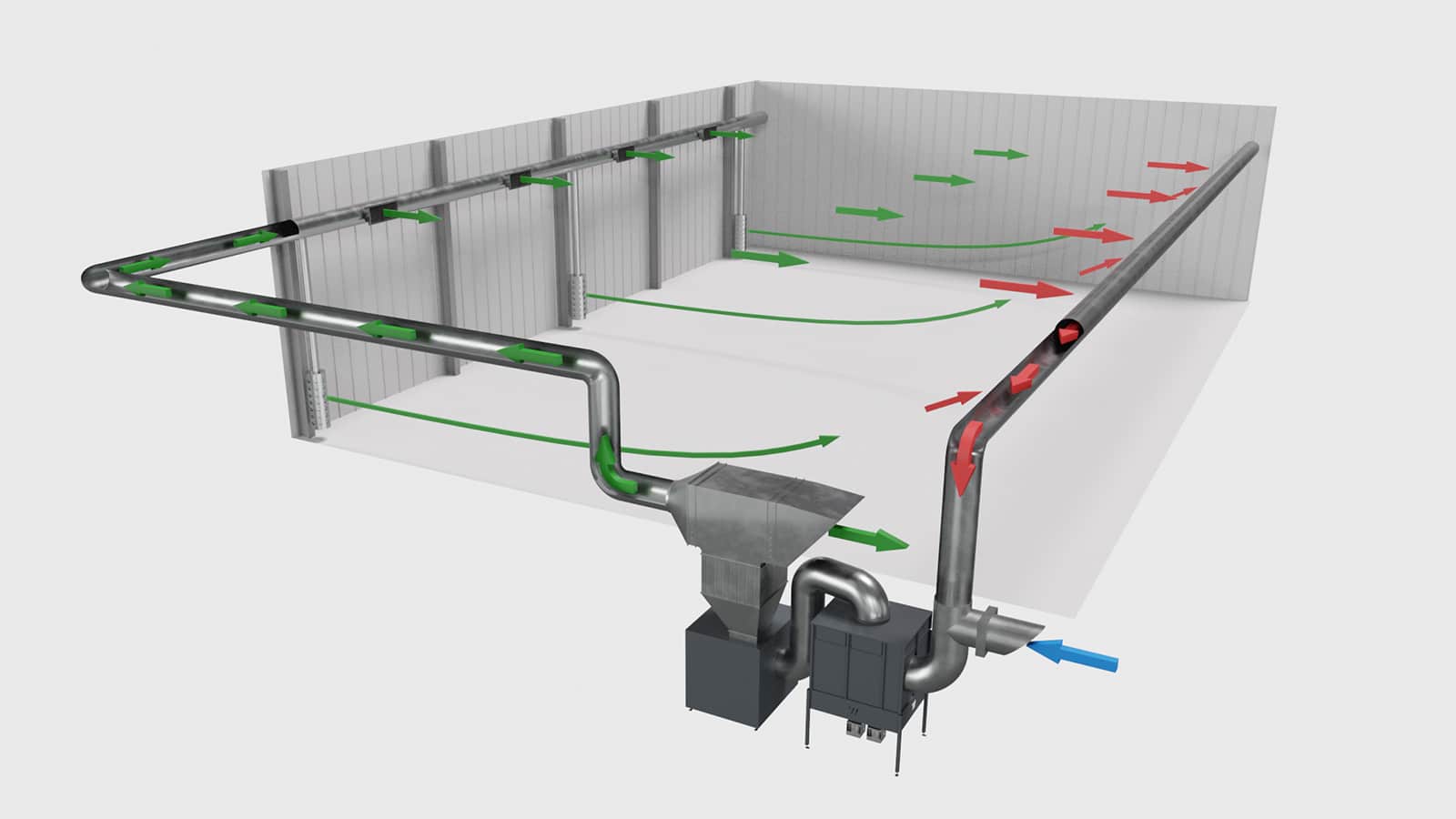

Individual extraction units for dry and wet separators

Our broad product portfolio ranges from dedusters, fume filters and wet separators to complete hall extraction systems or extraction cabins for a wide range of industrial processes. We offer customized extraction solutions and suitable pipe systems for almost every application in manufacturing companies. The extraction systems are specially tailored to your process, which makes them particularly energy-saving and powerful.

FUME FILTER

DEDUSTER

Wet separator