energy saving in production

Energy efficient extraction systems

In industry, targeted measures can save energy and resources and increase productivity. As a manufacturer of extraction systems, we fully exploit the potential of our systems to offer you a sustainable and economical solution.

Extraction units from ABSAUGWERK mean low resistance and maximum efficiency.

FILTER TOWER

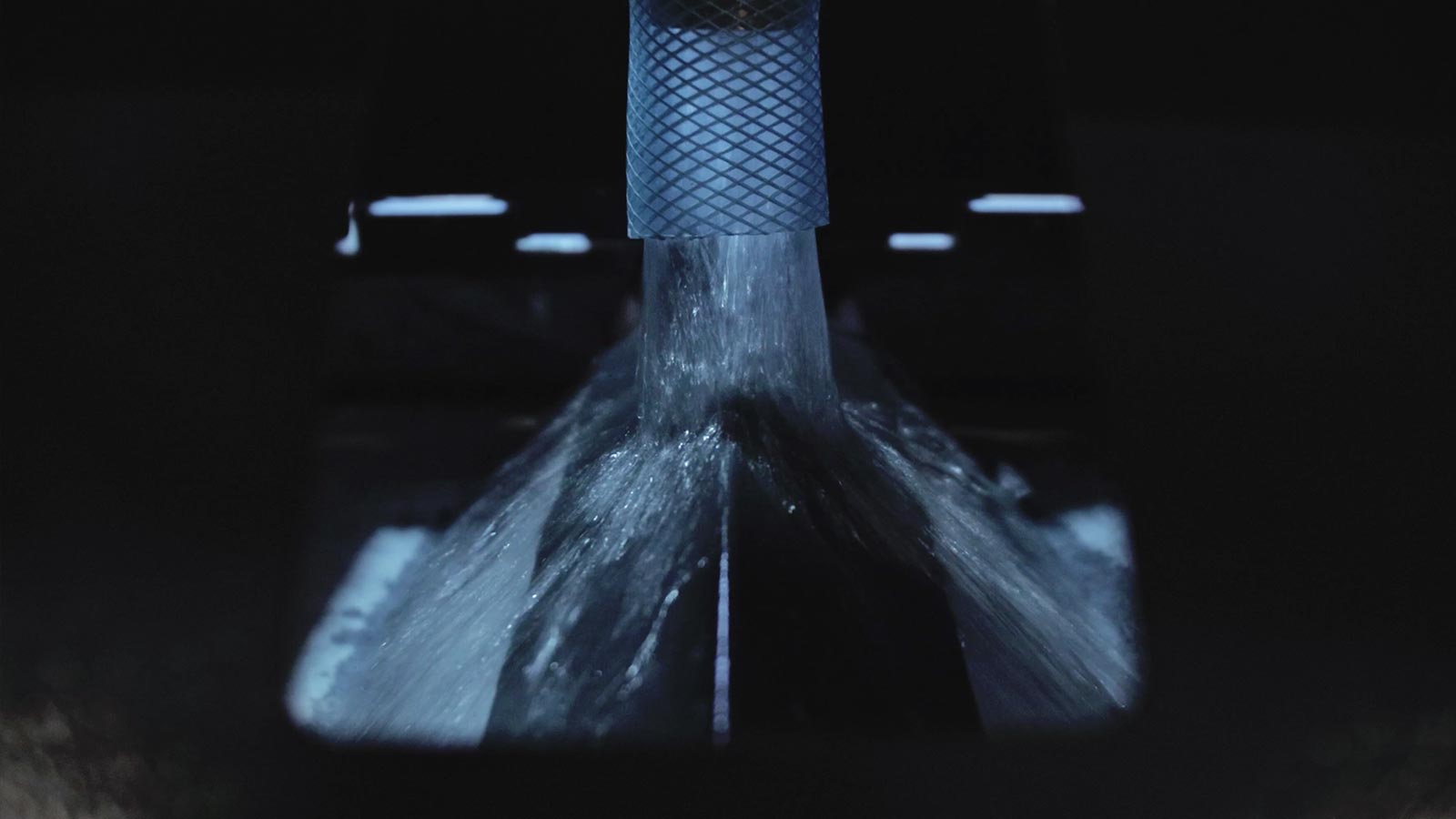

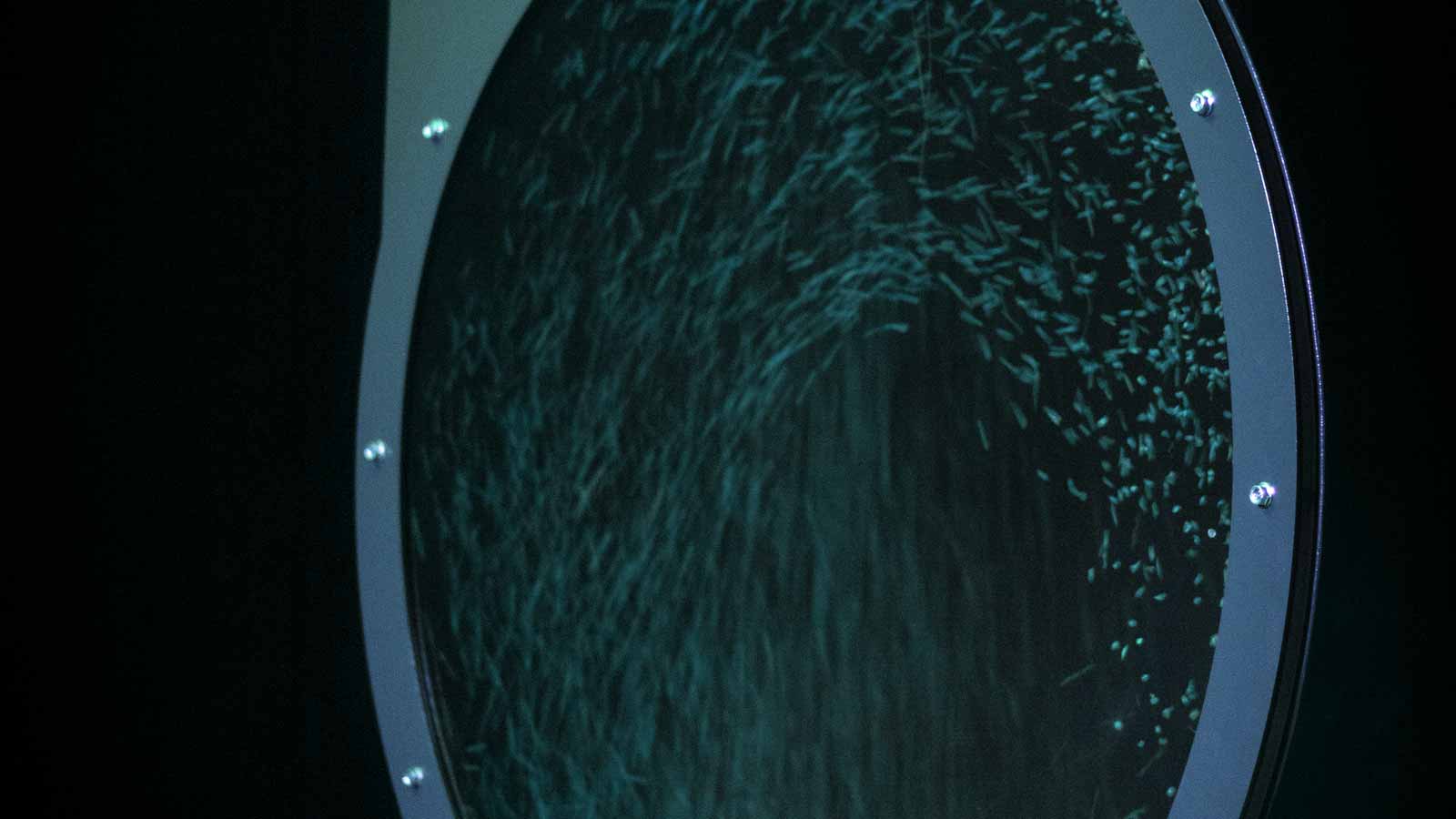

Wet separator

FUME FILTER

DEDUSTER

Energy efficiency means using available energy in such a resource-efficient way that the desired benefit can be achieved. An extraction unit is energy-efficient if it delivers the required extraction performance with as little electricity as possible. However, it also means using as little heating and cooling energy as possible to keep the building at the right temperature. Overall, the less energy required to achieve the required output, the greater the energy efficiency and cost-effectiveness.

It is still common practice to value investment projects in ventilation systems, such as extraction systems, filter systems and ventilation systems, primarily on the basis of acquisition costs. With this approach, only the immediately visible investment costs are considered, but the ongoing operating costs remain hidden. We continuously optimize our units and ensure long filter service lives, minimal power and water consumption, few service calls, heat recovery, automatic performance adjustment and much more

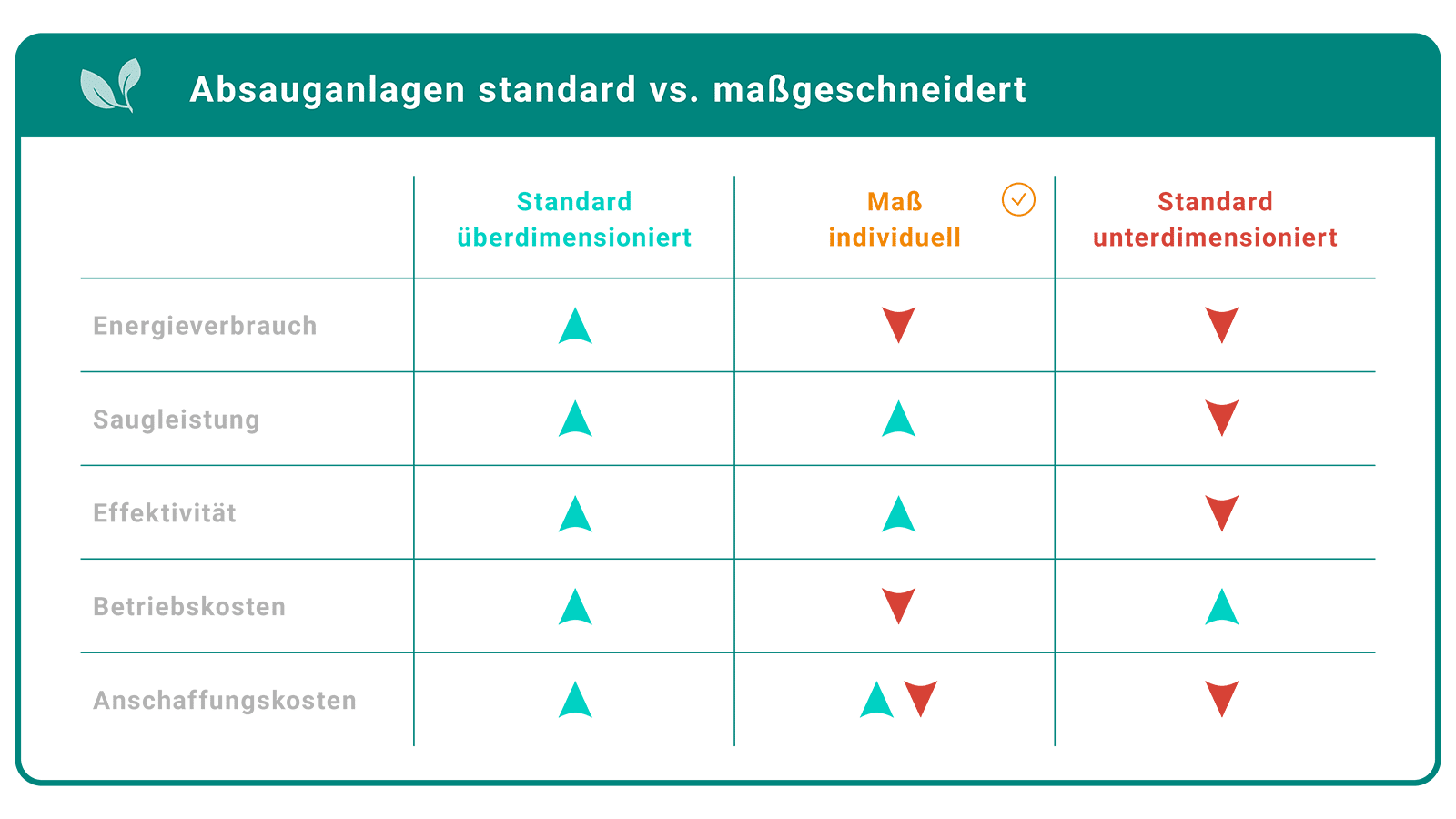

Customized extraction solutions

Off-the-shelf extraction units are usually oversized or undersized. This has a negative effect on performance or energy consumption. As a developer and manufacturer of extraction units, we offer complete solutions including capture, discharge, pipe system and other accessories. In this way, synergies of the individual components are exploited, air resistance is minimized across the board, and thus more extraction power is achieved with less kW.

Energy saving in production

There are many ways to save energy in production halls: Lighting, heat supply, electrical drives. The right ventilation technology plays a decisive role in this. The following parameters must be considered for energy-saving extraction.

System design

- Correct dimensioning

- Little air resistance

- Flexible construction

- Optimally designed pipe system

- ATEX and fire protection measures

Filter system

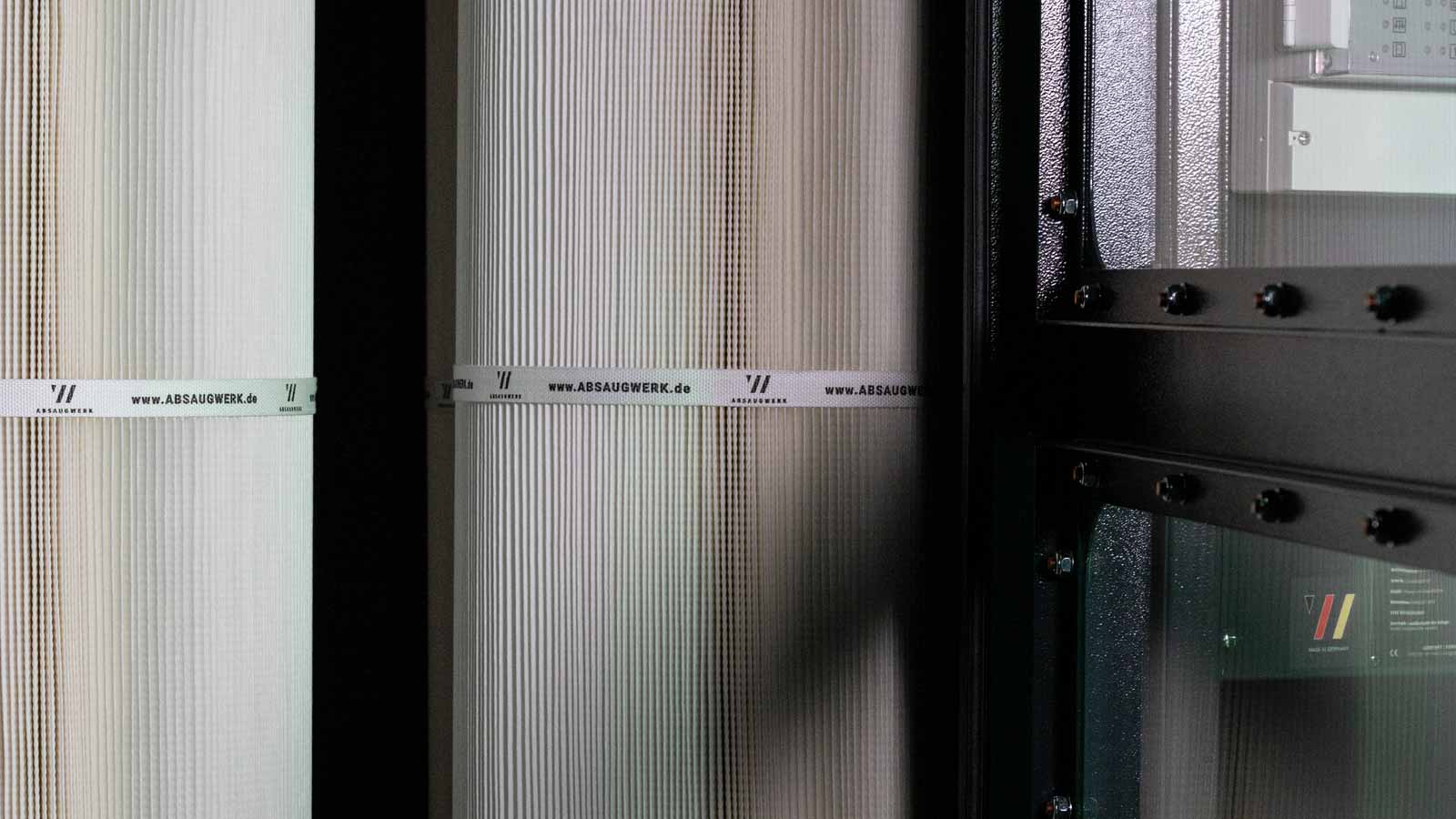

- Durable quality filters

- Cleanable metal mesh filters

- Regular Jet-Pulse filter cleaning

- Filter protection with precoat unit

- High volume post-filter

Control & drive

- Energy-saving EC and AC fans

- Automatic power adjustment

- Airflow control

- Automatic extinguishing device

Recirculation mode

- More energy-saving than exhaust air mode

- Less piping required

- Less maintenance/cleaning required

- Preservation of heat in the air

heat recovery

- Summer/winter switchover

- Recycling of the exhaust air heat

- Temperature controlled fresh air function

- 70% heating cost saving

- Government financing options

Resource saving

- Water savings up to 5,200 L/year through recovery

- Recovery of the separated media

How can I produce more sustainably?

Sustainable management and production is becoming increasingly important, regardless of the industry. Sustainability does not stop at environmental protection and cost efficiency. Health and safety also play a major role. A physically healthy production worker will remain efficient for a long time, will be motivated and the quality of his work will increase.

Save energy

Reduce heating and electricity requirements

Conserve resources

Waste less water

Save toads

Reduce operating costs

Stay healthy

Fewer pollutants =

fewer cases of illness

Prevention

instead of aftercare

Regular

cleaning & maintenance

Reduce waste

Recycle materials

Work safely

Set up EX and fire protection

Precision and

high quality

Extend product life

A sustainable investment

Resistant design and use of robust materials, as well as improvement of serviceability and reparability, result in a long service life of our extraction systems.

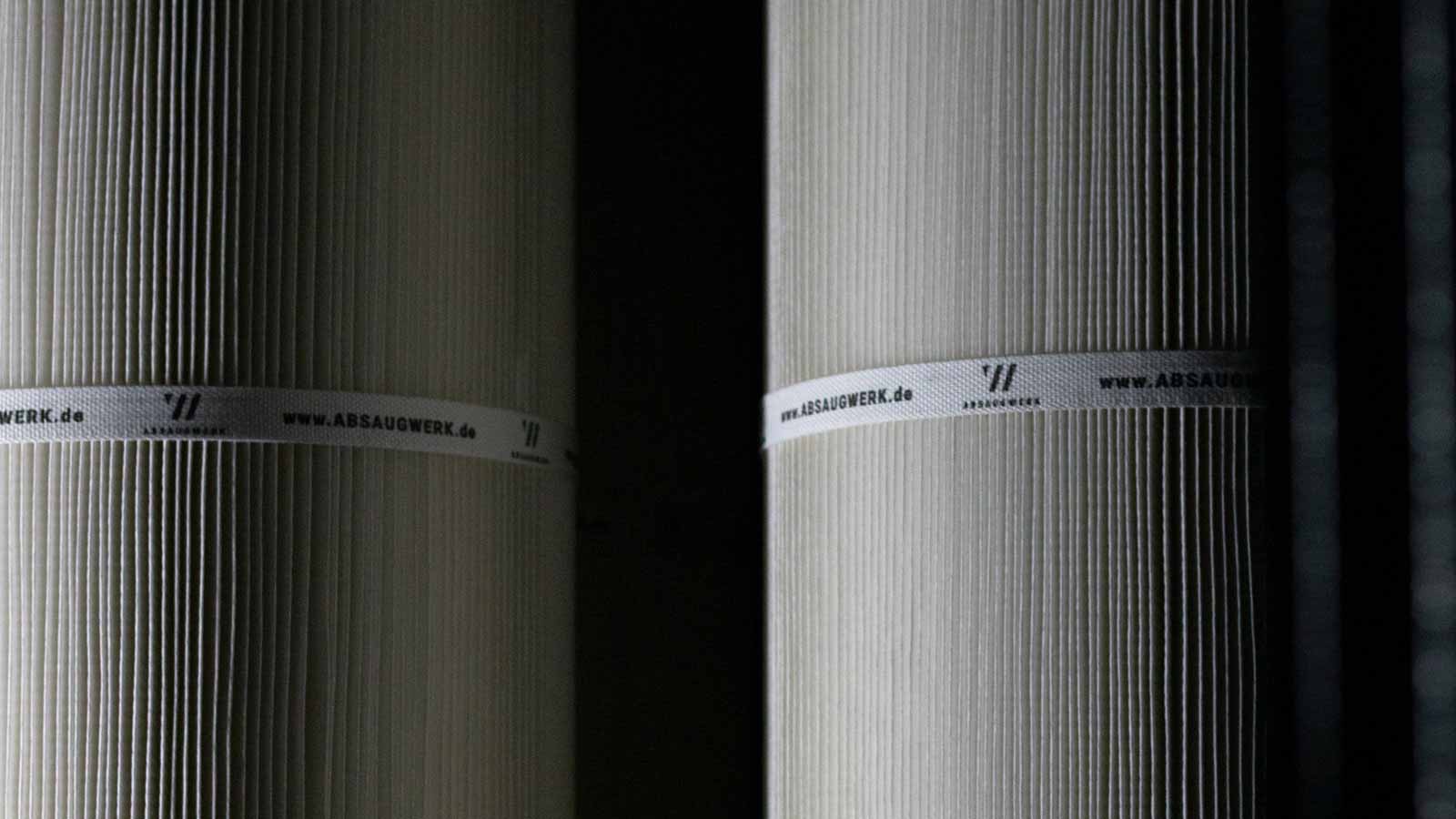

Premium filter protection

The filters are automatically and continuously dusted with a so-called precoating agent (e.g. slaked lime). This prevents the filter lamellae from sticking together and significantly increases the filter service life.

Filter cleaning and change

Added filters provide increased resistance to airflow and unnecessarily high energy consumption. The Jet-Pulse filter cleaning system automatically blows the dust off the filters with compressed air.

Pre-separator

These system components serve as spark traps or for separating large quantities of dust and chips before they reach the filter unit. They protect the filters and the air resistance in the plant remains constantly low.

Retrofit

Retrofitting and modernizing with new, up-to-date technology can often make a lot of sense. Our extraction systems are modular. We make sure that individual parts can be replaced and mechanics repaired.

Sustainable materials

We use materials that extend the technical life. This means that fewer products have to be reproduced, which in turn saves energy and materials.

All services directly from the manufacturer

As a competent partner, we support you throughout the entire product cycle. From the initial consultation to the planning and implementation of the systems. And that’s not all. Even though our systems require very little cleaning and maintenance, they still need to be checked from time to time. With us you can expect a comprehensive maintenance and spare parts service. Via third-party maintenance, we can even access your systems worldwide and provide immediate support if required.

Honest & competent advice

Together we will find the optimal extraction solution for your application – economical and future-proof.

Cleaning & maintenance

To guarantee optimal operation and constant performance, we maintain our own and third-party extraction systems. In this way, deviations can be detected at an early stage and rectified cost-effectively.

Spare parts service

We can provide you with the right wear and spare parts to keep your system running for as long as possible.