FILTER UNITS

O SERIES | E SERIESFilter units can be set up individually or combined and extract several workstations at once. The extraction elements with separate fan are particularly suitable for large volumes of air and material. Series O and E filter units work on the same technical principle as oil mist separators and are ideal for the extraction of moist and sticky emissions.

Filter unit for aerosols, emulsions, vapors and mists

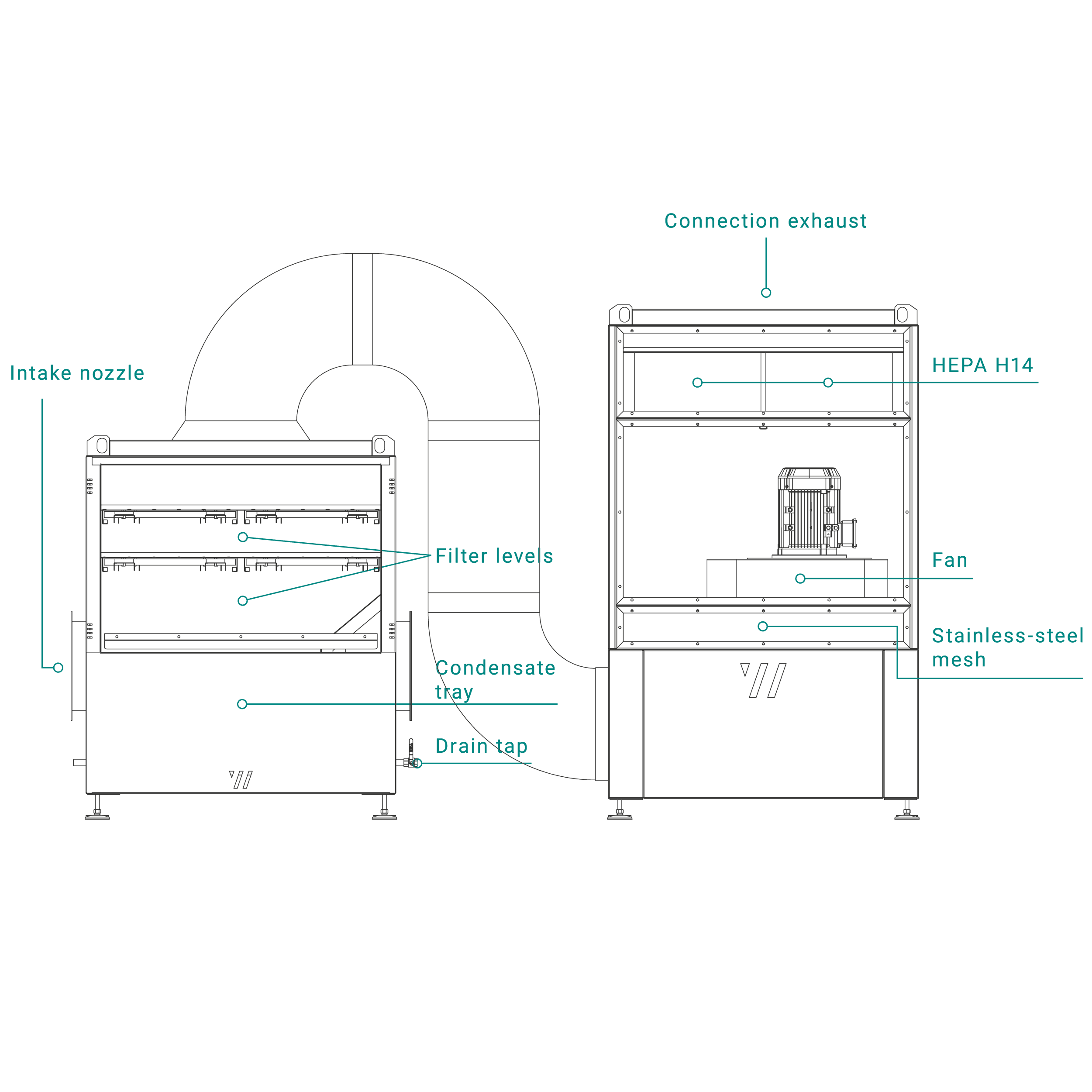

The O and E series filter units are available in various sizes and designs and bind aerosols, emulsions, steam or oil mist using high-quality filter media. A special stainless-steel metal mesh already separates a large part of the media and thus increases the filter service life many times over. The cleaned air can then be fed back into the hall (recirculated air) or outside (exhaust air).

As a manufacturer of filter units and extraction technology, we also develop individual systems for special applications.

-

For large amounts of air and media

-

Extraction of several individual workstations

-

Powerful fans

-

Planning and installation of the pipe system

-

Low height and footprint

-

Robust and weather resistant

-

Recirculating air or exhaust air operation possible

MEDIA

Oil mist

Emulsion vapors

Aerosols

PROCESSES

Welding, cutting, turning, milling, soldering etc.

PERFORMANCE

max. 21,500 m³/h

per filter unit

Unit components

FILTER

- Cleanable stainless-steel metal mesh

CAPTURE

- Extraction arm

- Extraction table

- Extraction hood

- Machine connection

- Individual recording system

TECHNICAL DATA

- Motor power: 0.55–22 kW

- Fan capacity: 1,800–21,500 m³/h

- Operating time: 24 hours per day

DISCHARGE

- Siphon connection

Options & variations

HEPA H14 FILTER

Against carcinogenic substances

ACTIVATED CARBON FILTER

Against gases and odors

V2A-EXECUTION

Hygienic & stainless

HEPA H14 FILTER

Against carcinogenic substances

ACTIVATED CARBON FILTER

Against gases and odors

V2A-EXECUTION

Hygienic & stainless