ATEX deduster

Aluminum – Steel – Stainless steelOne deduster – three materials

When deburring, polishing or cutting aluminum and stainless steel, dusts are generated that can lead to serious fires or explosions due to chemical reactions. As a manufacturer of extraction systems, we have developed a special ATEX deduster that safely extracts and filters steel, stainless steel and aluminum even in mixed operation.

With our internal WERK development department, we also design individual extraction systems or special collection and discharge elements, specifically for your application.

Contact us for a no-obligation consultation, together we will find the optimal extraction solution!

Chemical reaction of aluminum and stainless steel

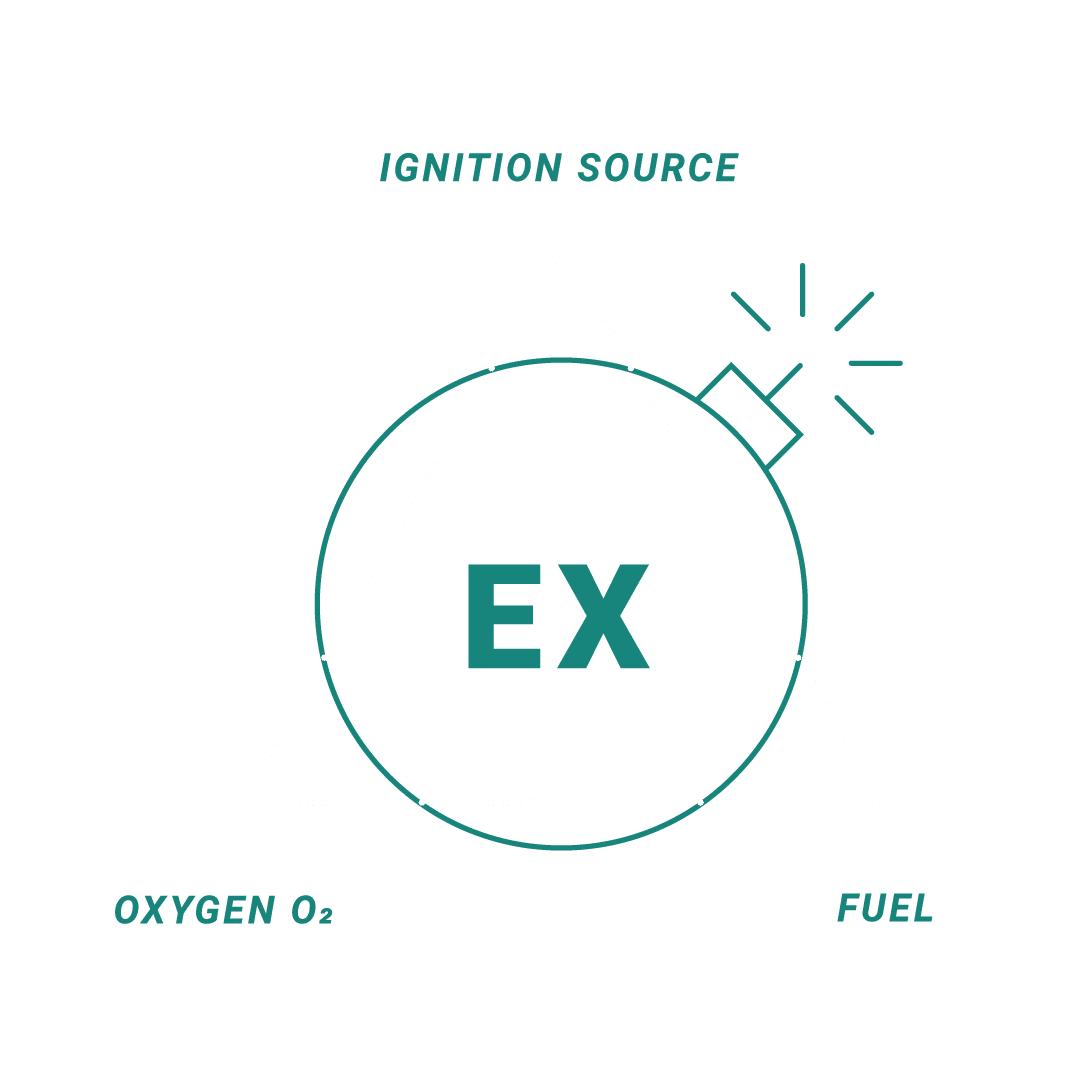

The machining of aluminum by grinding or sawing, for example, is usually accompanied by high levels of flying sparks. The resulting aluminum dusts are highly explosive in combination with oxygen and an ignition source. Therefore, extraction systems must comply with so-called ATEX directives.

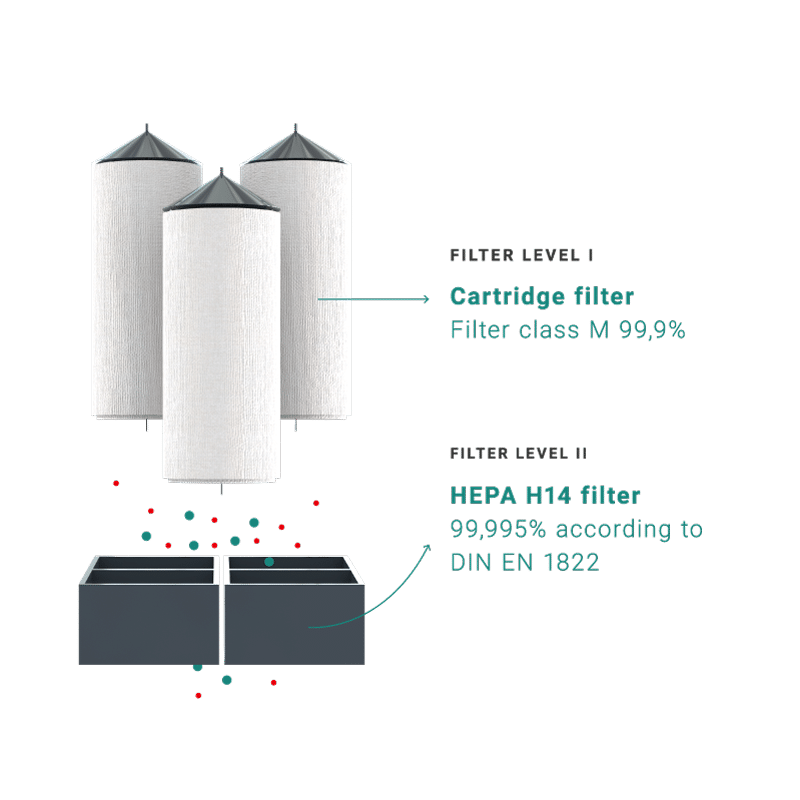

Again, stainless steel dusts released during industrial processing are highly carcinogenic and must be specially filtered in accordance with occupational health and safety guidelines. This is done via so-called HEPA filters, which separate particle sizes from 0.001 μm up to 99.995%.

If these dusts come into contact with each other, e.g. in a deburring machine, a self-igniting dust mixture is created by thermal reaction, which can set the machining center and other machines on fire. Again, stainless steel dusts released during industrial processing are highly carcinogenic and must be specially filtered in accordance with occupational health and safety guidelines. This is done via so-called HEPA filters, which separate particle sizes from 0.001 μm up to 99.995%.

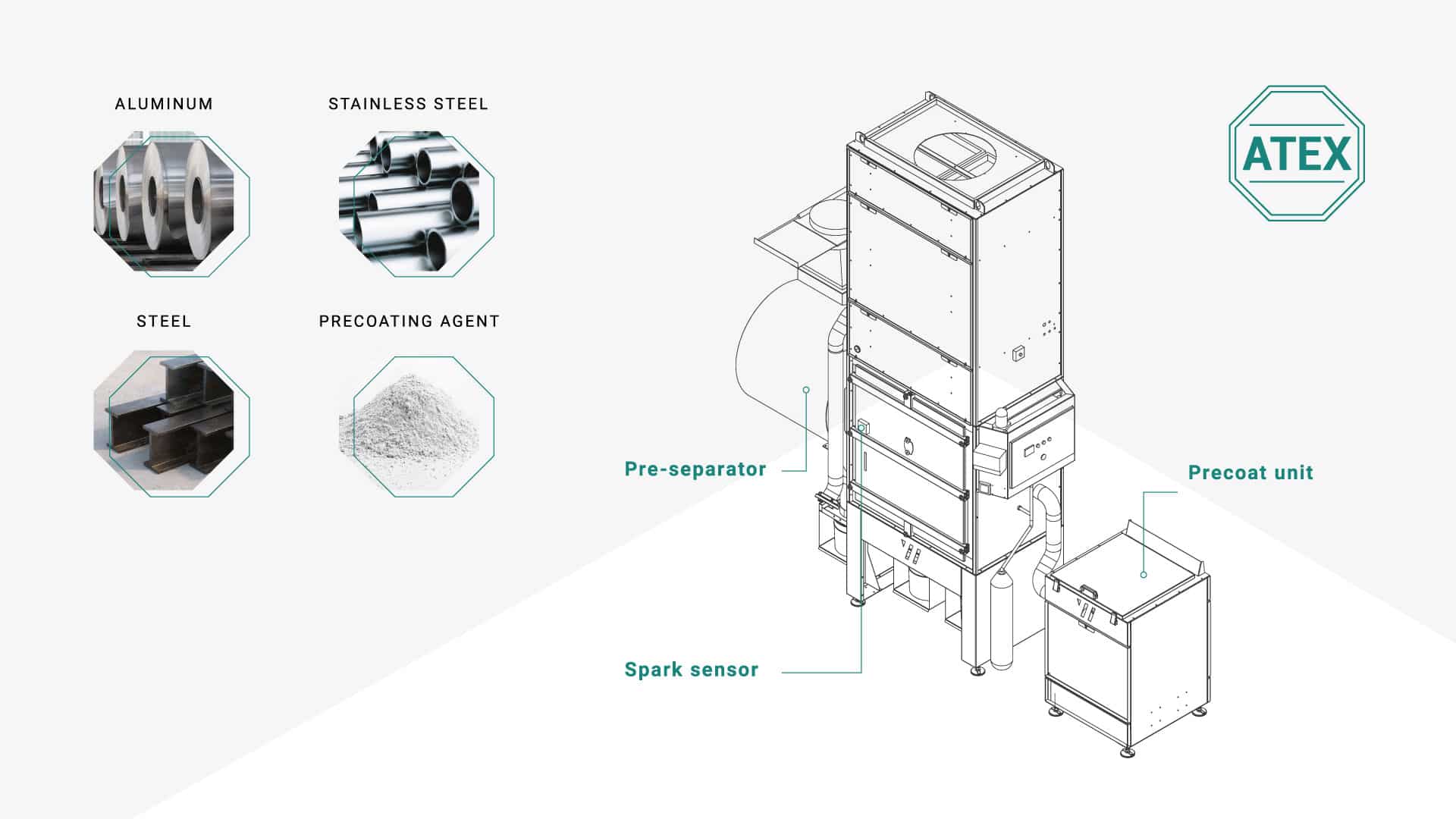

ATEX deduster mixed operation

In order to defuse the flammable dust mixture, we have developed a special extraction system for potentially explosive work areas in industry and trade, which can also be operated safely in recirculation mode. During planning and construction, we take various fire protection measures and build our extraction systems according to the primary explosion protection principle:

1. Precoat unit

A precoat unit continuously applies a precoating agent such as slaked lime to the filters in an extraction system. This reduces the material concentration of aluminum and stainless steel. The dosing of the precoating agent must be exact and continuous and is therefore doubly safeguarded.

2. Pre-separator

Before the extracted dusts reach the filter unit of the dedusting system, coarse particles and possible sparks are already separated in advance. In addition to fire protection, this also serves to extend the filter service life and ensures low follow-up costs. The filters have to be cleaned less frequently, which significantly reduces the downtimes of processing machines and increases productivity.

3. Spark sensor with extinguishing agent device

If a spark does reach the filter unit or if, contrary to expectations, a fire does develop, a radio sensor triggers the automatic extinguishing equipment (water, powder, CO₂) The filter unit then only has to be cleaned and new filters inserted.

4. ATEX design

To comply with ATEX regulations, extraction systems must be free of ignition sources and electrically conductive, and special ATEX components must be installed.

Your advantages

One unit for three

media: aluminum, steel,

stainless steel

Max. 15 min.

cleaning effort

per week

Up to 40% cheaper

than conventional

systems

Low operating and

follow-up costs

Up to 30% longer

filter service life

(HEPA H14 filter)

Installation in

interior possible

Customized extraction systems

To guarantee you an optimal and economical extraction system, our extraction systems are available in various sizes and numerous options. In this way, we keep operating and follow-up costs low, for a future-proof machine park.

PROCESSES

Sawing, cutting, grinding, polishing, deburring

MEDIA

Dust, fine dust, chips

Options & variations

HEPA H14 FILTER

Against carcinogenic substances

ACTIVATED CARBON FILTER

Against gases and odors

EXPLOSION PROTECTION

ATEX execution

Fire protection

Automatic extinguishing system

noise protection

Effective and safe

PRE-SEPARATOR

For large amounts of material

PRECOAT-UNIT

Premium filter protection

CROSS HEAT EXCHANGER

Effective heat recovery

DIFFERENT FANS

Medium/high pressure, high vacuum

INTELLIGENT CONTROL

Versatile operating options

unit color & branding

Individual as desired

Filter Technology ATEX Deduster

The dust-laden air is extracted via a capture element and a large proportion of the particles is already extracted in a pre-separator. The air flow then passes through two filter levels and can be cleaned and returned to the hall or outside.